FEATURES - 13

COROB™ D600 - D700 - D800 EXTRA

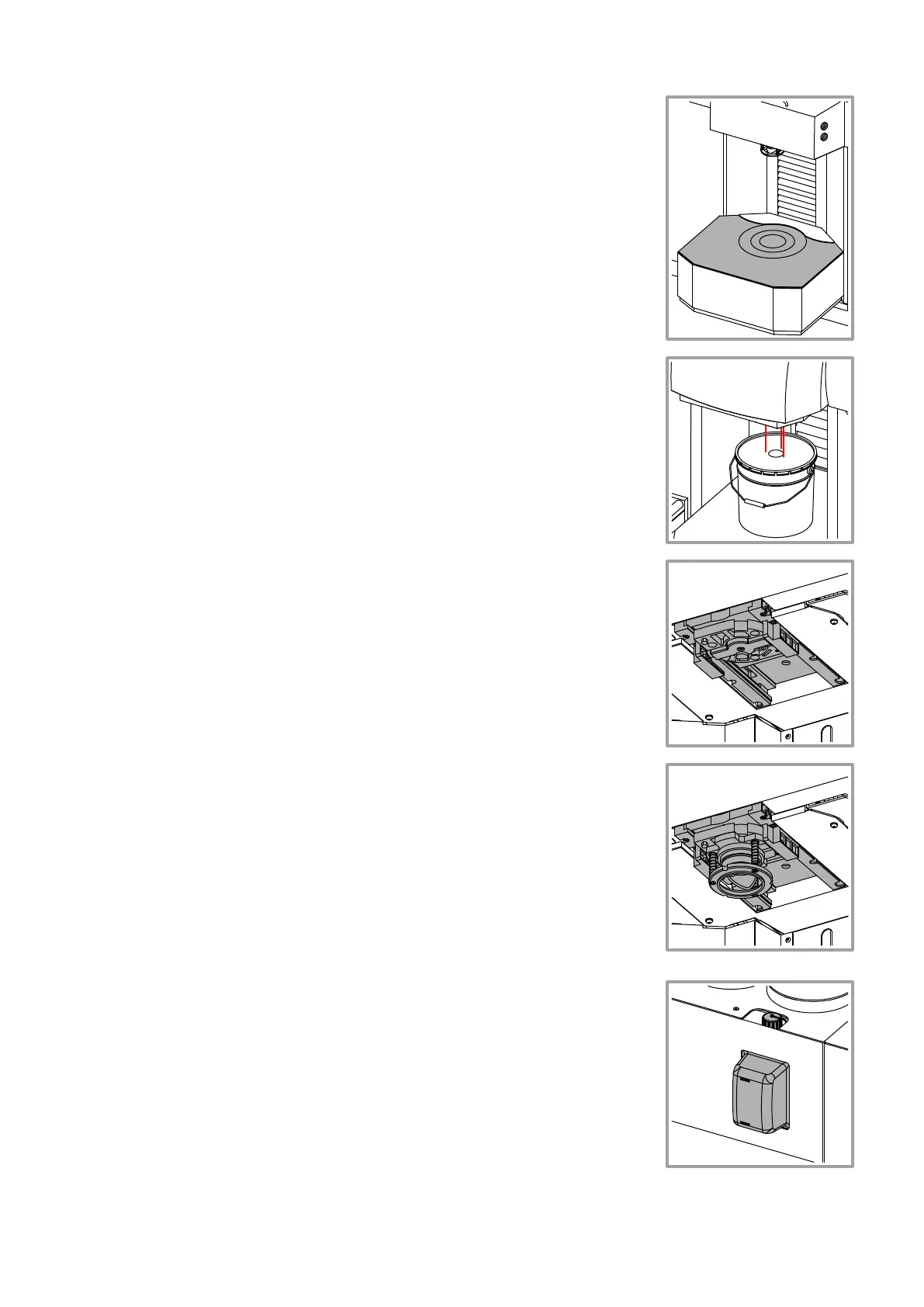

Can centering device

On the machine accessorized with punching system, a centering device is

mounted on the shelf. The can centering device is custom-made based on the

size of the cans to be handled and is useful for aligning them with the nozzle

center, so that the can lid is punched in the middle and dispensing takes place

precisely into the hole created. The can centering device is also available as an

optional accessory to the standard machine, useful for positioning pre-punched

cans right under the dispensing center.

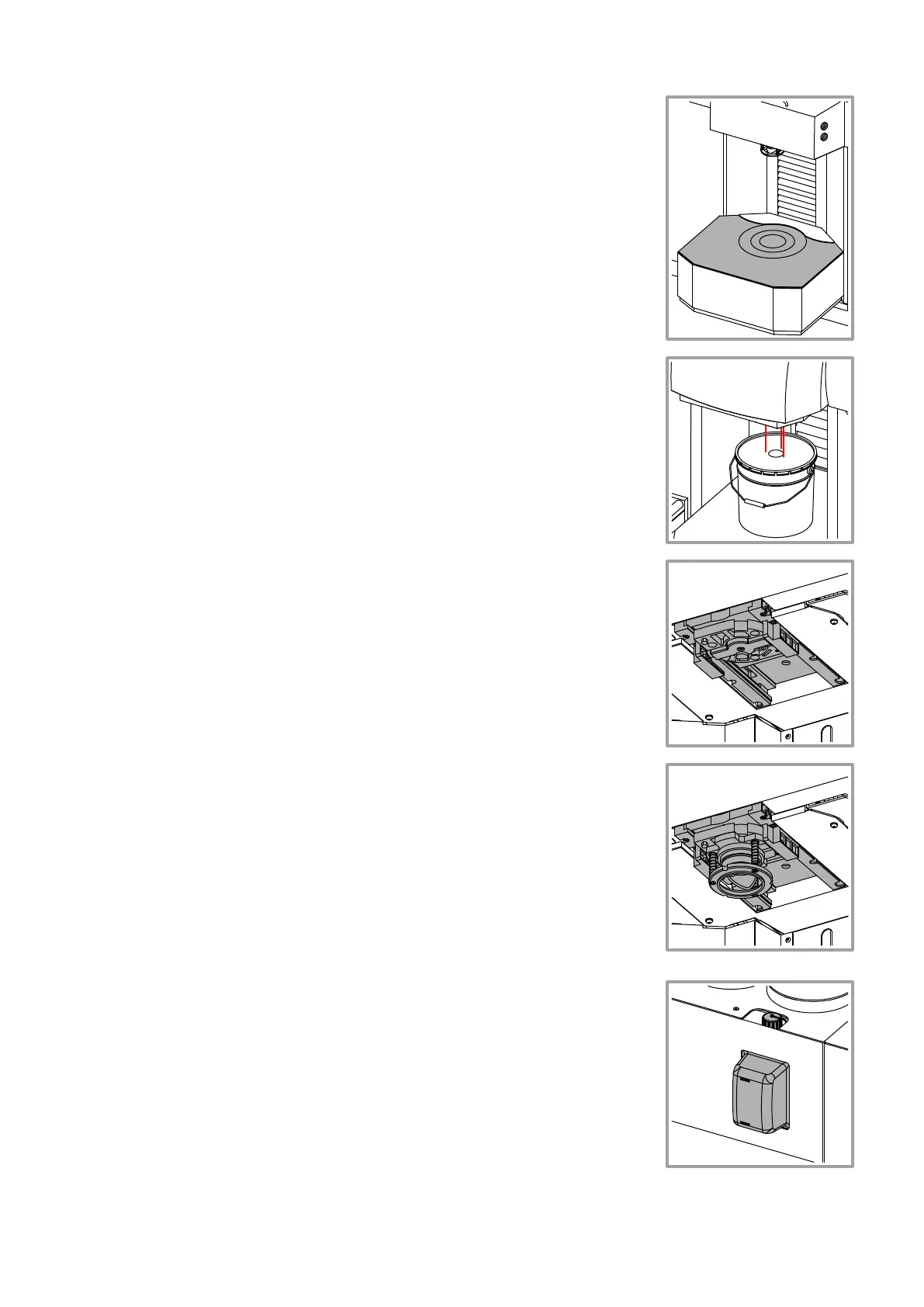

Bung Hole Locator (B.H.L.)

This is a system that emits laser beams that allow the positioning of pre-punched

cans, so that the hole is in line with the center of the dispensing nozzles.

Nozzle Humidier Cap

Colorants tend to dry out; this tendency may be more or less strong depending

on the type of colorant and the environment conditions (temperature, relative

humidity, etc.). To prevent colorants from drying out in the nozzle center, the

machine is equipped with a humidier cap which requires constant maintenance.

The Lift-up Autocap is an automatic humidier cap which ensures that

the nozzles are hermetically sealed. It is managed by the software,

which opens it automatically before dispensing and closes it immediately

afterwards.

Manually-operated automatic puncher

The puncher is a device that perforates the can lid. Punching is carried out by

the operator by pushing contemporaneously the semiautomatic shelf activation

buttons (two-handed control); thanks to the upward movement, the shelf pushes

the can resting on it against the puncher, and with a downward movement

brings it to the correct position for dispensing.

No-Dry-Nozzle Humidier System

The humidier system for water-based colorants guarantees the nozzles are

humidied not only with Autocap closed but also during dispensing. The air,

humidied by the water contained in the bottle, is transferred to the nozzles

area. Based on the humidity level detected, the system activates or shuts off

whenever needed.

The humidier system for solvent-based colorants humidies the nozzles when

Autocap is closed. The solvent, contained in a small tank inside the Autocap,

keeps the nozzles area constantly saturated.

The two systems can be used individually or together according to the tinting

system used on the machine.

MAX

MIN

Loading...

Loading...