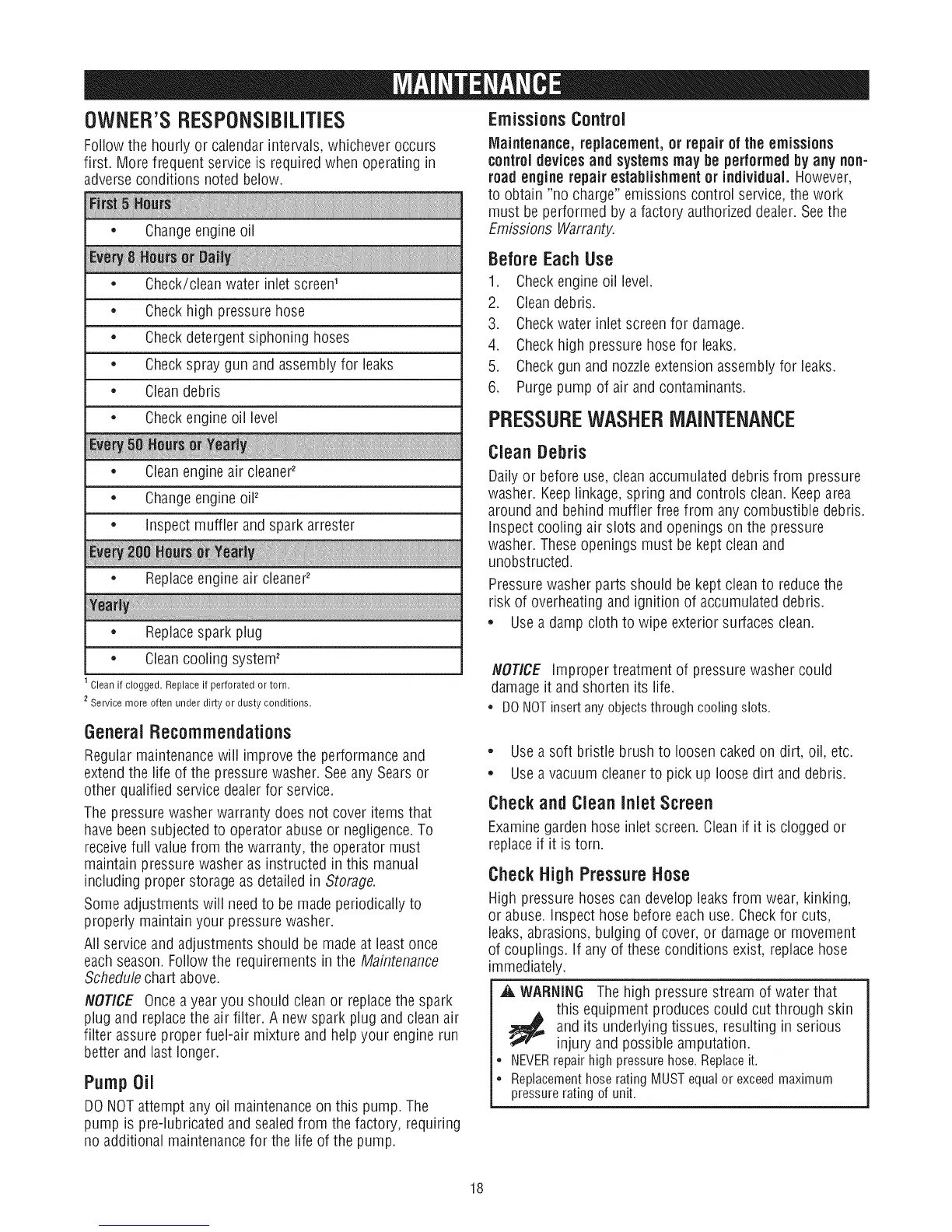

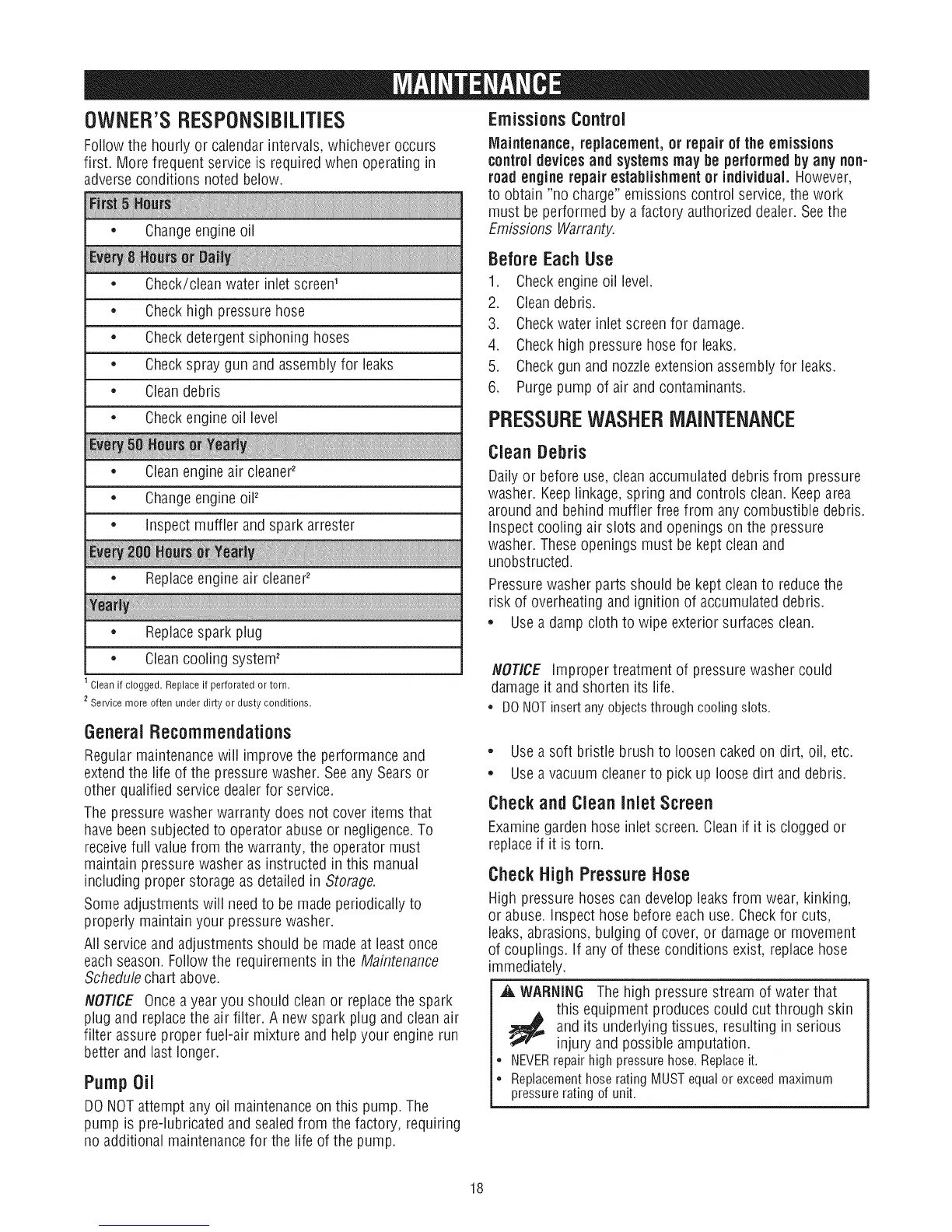

OWNER'SRESPONSiBiLiTiES

Follow the hourly or calendar intervals, whichever occurs

first. More frequent service is required when operating in

adverseconditions noted below.

ii ii _ i iiii iiii ]i i;;iiii_ii_i{ii_i!_i!i}iiiii}}iiiiJii}iiiii_ i{__ii _!Ji}iiii_i_i}_ii iiH_iiiiii i]iiii iiii iiiiii iiii iiiiii iiii iiiiii iiii iiiiii iiii iiiiii iiii iiiiii iiii iiiiii iiii iiHHHHHHHHH_

• Changeengine oil

iiiiiiiiii,'_iiiiiiiiii;1; ; ;; ;;; ;; 3 ;

• Check/clean water inlet screen'

• Checkhigh pressure hose

• Checkdetergent siphoning hoses

• Checkspray gun and assembly for leaks

• Cleandebris

• Checkengine oil level

!i{i;;iiiiiiiiiiii_iiiiiiiiiiiiiiiii]i/i;;iii iiii _} iii ii_ i{i iiiiiii i HH:::::__i_ii

• Cleanengine air cleaner_

• Changeengine oil_

• inspect muffler and spark arrester

• Replaceengine air cleaner_

• Replacespark plug

• Cleancooling system_

Clean if clogged. Replace if perforated or torn.

2Service more often under dirty or dusty conditions.

GeneralRecommendations

Regularmaintenancewill improve the performance and

extendthe life of the pressurewasher. Seeany Searsor

other qualified service dealerfor service.

Thepressure washer warranty does not cover items that

havebeensubjected to operator abuseor negligence.To

receivefull valuefrom the warranty, the operator must

maintain pressurewasher as instructed in this manual

including proper storage as detailed in Storage.

Someadjustments will needto be made periodically to

properly maintain your pressurewasher.

All service and adjustments should be made at least once

eachseason.Follow the requirements in the Maintenance

Schedulechart above.

NOTICE Oncea year you should clean or replace the spark

plug and replacethe air filter. A new spark plug and clean air

filter assure proper fuel-air mixture and helpyour engine run

better and last longer.

Pump Oil

DONOTattempt any oil maintenance on this pump. The

pump is pre-iubricated and sealedfrom the factory, requiring

no additional maintenancefor the life of the pump.

EmissionsControl

Maintenance,replacement,or repair of the emissions

control devices and systemsmay be performedby any non-

roadengine repair establishment or individual. However,

to obtain "no charge" emissions control service, the work

must be performed by a factory authorizeddealer. Seethe

Emissions Warranty.

BeforeEachUse

1. Checkengine oil level.

2. Cleandebris.

3. Checkwater inlet screenfor damage.

4. Checkhigh pressure hose for leaks.

5. Checkgun and nozzleextension assemblyfor leaks.

6. Purge pump of air and contaminants.

PRESSUREWASHERMAINTENANCE

Clean Debris

Daily or before use, clean accumulateddebris from pressure

washer. Keeplinkage, spring and controls clean. Keeparea

around and behind muffler free from any combustible debris.

inspect cooling air slots and openings on the pressure

washer. Theseopenings must be kept clean and

unobstructed.

Pressurewasher parts should be kept clean to reduce the

risk of overheating and ignition of accumulated debris.

• Usea damp cloth to wipe exterior surfaces clean.

NOTICE improper treatment of pressurewasher could

damageit and shorten its life.

• DONOTinsertanyobjectsthroughcoolingslots.

• Usea soft bristle brush to loosen caked on dirt, oil, etc.

• Usea vacuum cleaner to pick up loosedirt and debris.

CheckandClean Iniel Screen

Examinegarden hose inlet screen. Cleanif it is clogged or

replaceif it is torn.

CheckHighPressure Hose

High pressure hoses candevelop leaksfrom wear, kinking,

or abuse, inspect hose beforeeachuse. Check for cuts,

leaks,abrasions,bulging of cover, or damage or movement

of couplings. If any of these conditions exist, replace hose

immediately.

,A WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

, NEVERrepairhighpressurehose.Replaceit.

• ReplacementhoseratingMUSTequalor exceedmaximum

pressureratingofunit.

18

Loading...

Loading...