12

Auto Levelling

• Navigate to the Info screen, then Motion, and choose Level Bed. Return to the

info screen afterward.

• Access the Info screen, then Configuration, and select Store Settings. (Save Z-axis

compensation data.)

• Go to the Info screen, then Print from Media, choose the desired print file, and

initiate the printing process.

• On the Info screen, go to Configuration, then Probe Z offset. After the printing

starts, monitor the filament's adhesion to the glass platform and make necessary

adjustments to the Z-axis compensation value accordingly.

Wrong: The nozzle is too far away from the platform, causing poor adhesion, and the

filaments are unable to stick properly.

Right: Filaments are extruded evenly and adhere well to the platform.

Caution: The nozzle is too close to the platform, resulting in insufficient filament

extrusion and potential scraping of the platform.

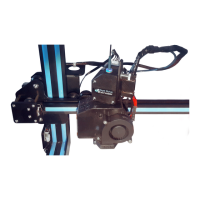

Filament winding

• When waiting for the temperature to rise, hang the filament over the filament

holder.

• Press the extrusion clamp and insert the filament along the extruder hole up to

the nozzle. Once the temperature reaches the target value, you will observe a

flow of filament at the nozzle, indicating that the filament has been loaded.

Note: For smoother printing, cut the end of the filament.

To replace the filament

When the printer is not in operation:

• Heat the nozzle to above 185°C first, wait for the filament inside the nozzle to

soften, then press the extrusion handle and quickly pull out the filament to

prevent it from getting stuck at the heat break.

• Replace the new filament onto the rack frame and repeat the loading procedure

above.

Loading...

Loading...