2.6 Safety Informaon

Electrical Safety

Other safety aspects

Policy of equipment requirements

Mechanical safety

Chapter 3: Installaon Site and Environmental Requirements

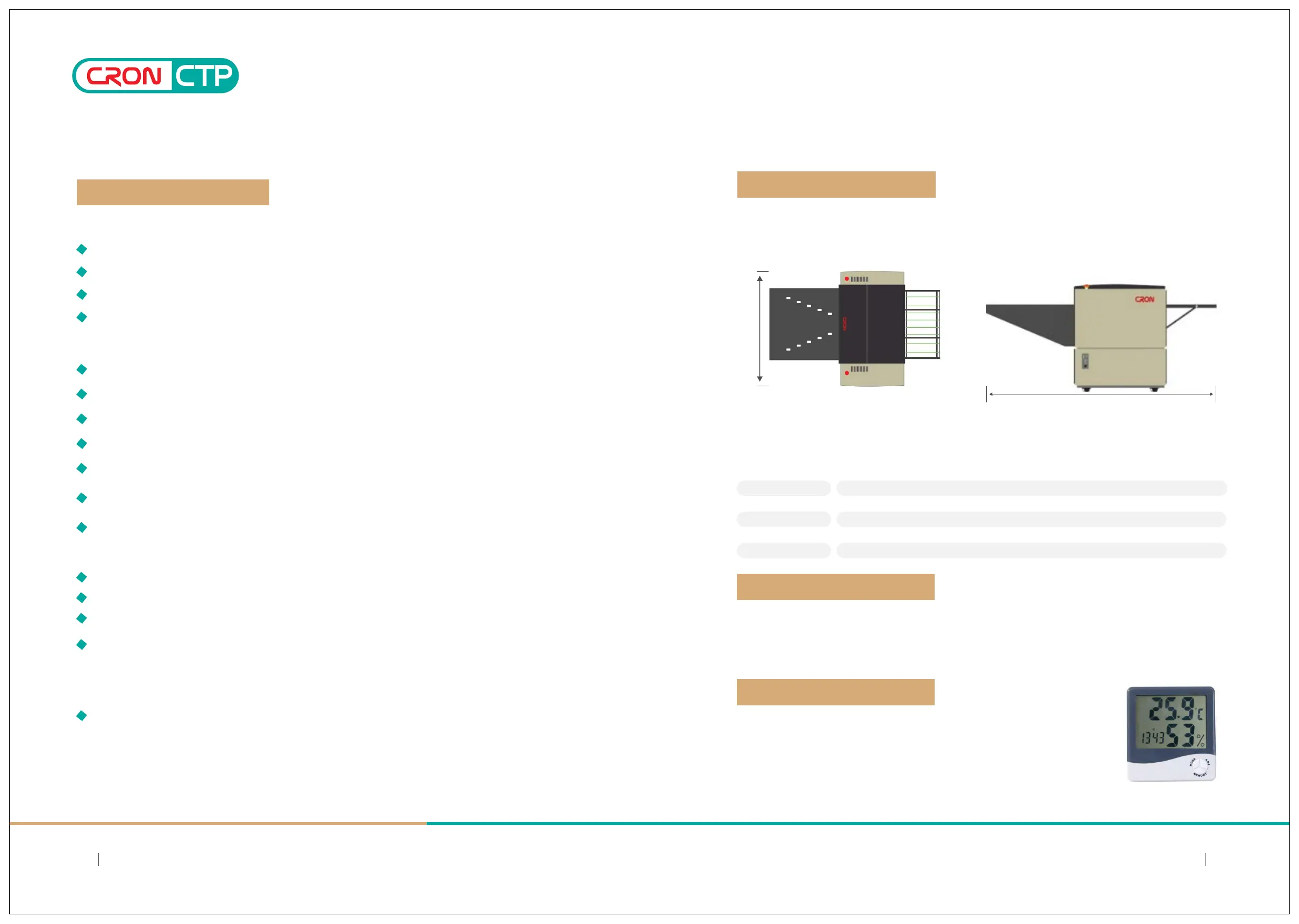

3.1 Space requirement

3.2 Flooring & hallway access

3.3 Environmental requirement

Table 3-1: System equipment size and installaon space required(Includes loading table+output bridge)

W

L

Device Model

Equipment Size

W(m)

TP26H/TP26G+

TP36H/TP36G+

TP46H/TP46G+

TP60H/TP60G+

TP72H/TP72G+

1.4

1.7

1.9

2.3

2.7

2.1

2.1

2.7

2.8

4

3.4

3.7

3.9

4.3

4.7

4.1

4.1

4.7

4.8

6

Equipment Size

L(m)

Installaon Space

W(m)

Installaon Space

L(m)

Table 3-1

Chapter 2: Overview

Equipment must be grounded effecvely;

To protect the equipment and personal safety, it is recommended to install indoor lightning arresng rod;

All maintenance work on the equipment must be carried out with the power off;

When the equipment is working, do not touch the moving parts of the machine with your hands or fingers.

Only under the circumstances necessary to dismantle the device casing;

Be aenon to the machinery operaon, always wear gloves, tools and parts must be placed in an orderly

manner;

Do not perform any maintenance or modificaons to the equipment system that is not authorized by CRON.

Do not place any foreign objects on the device;

In non-emergency situaons, it is strictly prohibited to press the emergency stop buon;

In the operaon of mechanical parts, always wear gloves, so as to avoid rusng parts; tools and parts should be

placed in order;

Avoid overhead collision during equipment operaon.

This device is not intended to be used in an explosive or potenally explosive atmosphere.

Fireworks is prohibited near the occasion of this device;

Prevent water or other liquids from flowing into the interior of the device;

Debris, scrap or residue generated from the use of this equipment must be handled in accordance with the laws

and regulaons of the hazardous material management authority in the country / region in which it is used.

To ensure that customer’s installaon site, environment and condions, are able to meet and comply to the

equipment operaonal requirements.

Refer to Table 3-1, given the size of the machine and consider the space needed, minimum distance between

wall and machine is 100cm, sizes of the room(space) needed for the machine installaon can be determined. It

is also advisable to reserve some room space close to the installed machine for placement of plates and media

too.

Doors and corridors at the installaon site must be wide enough ( 145cm) so that the machine can be

pushed into the room.Floor level should be maintained at ± 4mm. If installaon to be done above ground floor,

this requires an industrial elevator that have can load more than 2000kg. Aer the machine is in place, the

machine requires leveling by using a level gauge.

Working room temperature: 18°C ---- 28°C

Environment humidity: 40% ---- 60%, Non-condensing

Air quality: should meet internaonal quality standards, that is, API value

is less than or equal to 100;

Other installaons for indoor: Air-condion, Dehumidifier/humidifier, air

purifier.

1110

SIMPLE AND DIRECT 丨 STEADY 丨 MAJOR

SIMPLE AND DIRECT 丨 STEADY 丨 MAJOR

Loading...

Loading...