6.1.2 Built-in Punch connecon

Chapter 6: Oponal Devices

6.1Built-in Punching

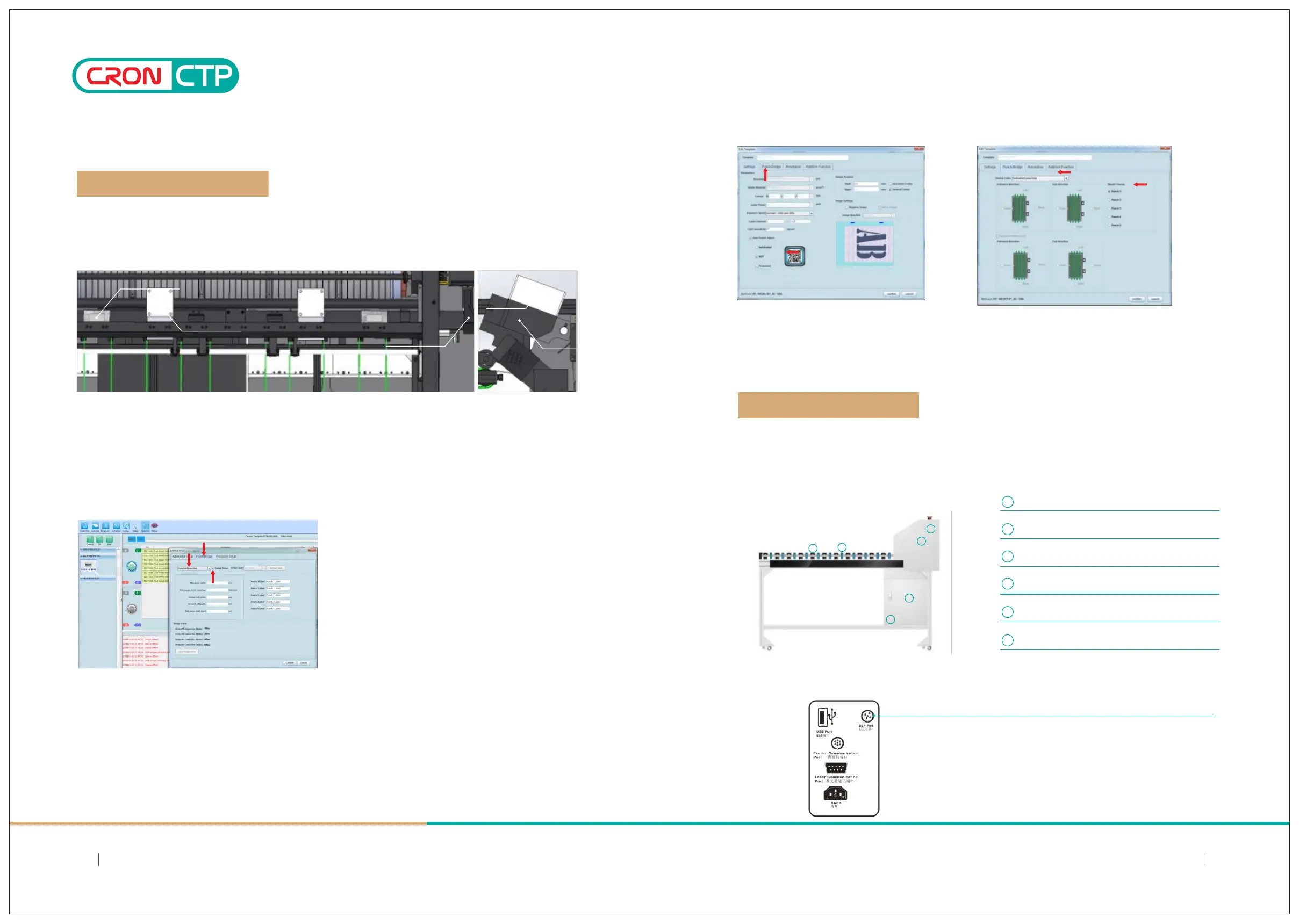

6.1.1 Built-in Punching structure

6.2 BGP Punch Bridge

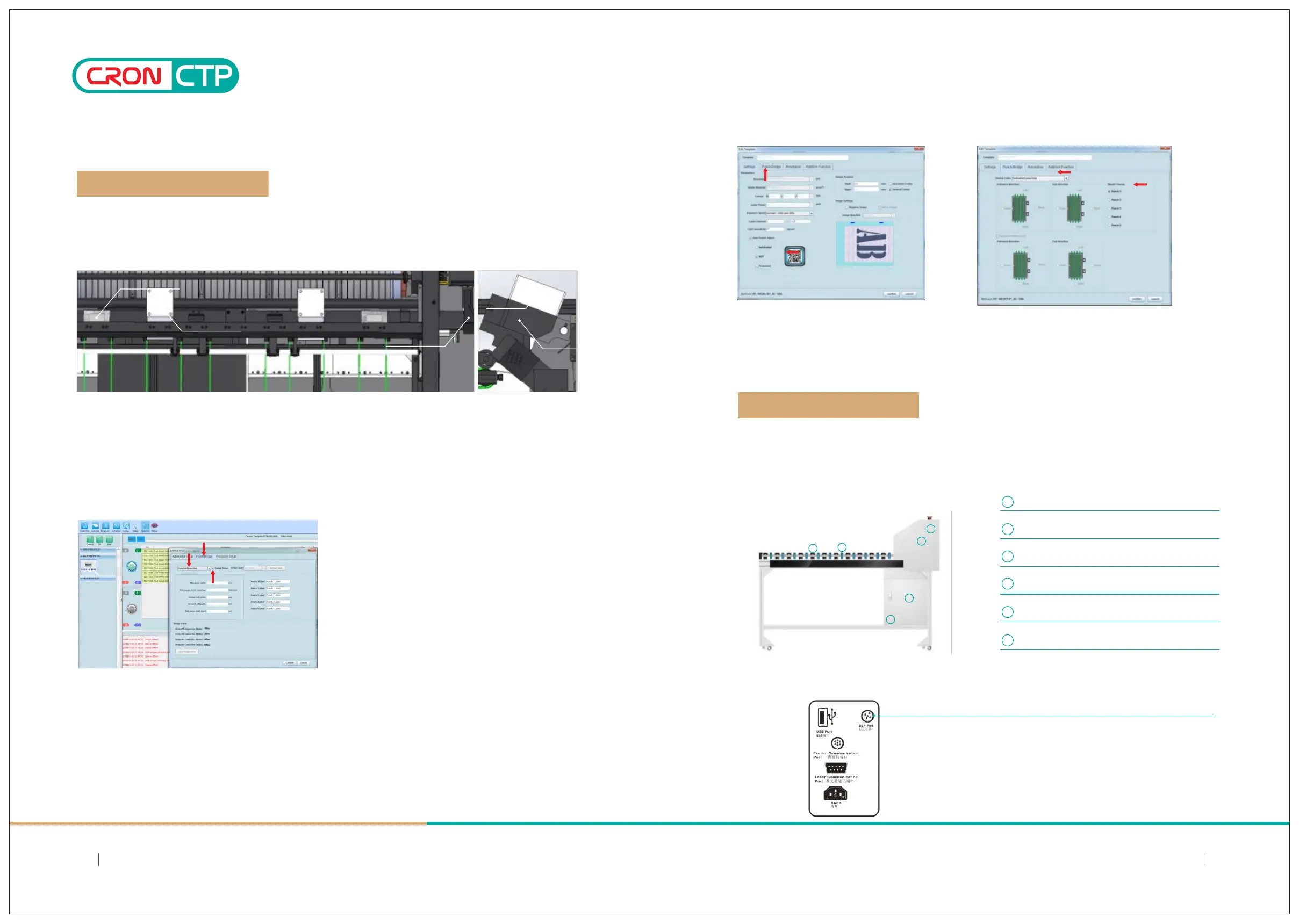

6.2.1BGP Punch Bridge structure

6.1.3 Built-in Punch sengs

6.1.4 Built-in Punching maintenance

Reserved notch

Die punch components

Chuds removal tube

Die punch

Air Cylinder

BGP Interface port connecon

1

6

2

3

4

5

1

6

2

3

4

5

Built-in punching is an oponal peripherals, it is a module that can be integrated onto CTP equipment, to

provide precise registraon on punching while having plat mounted at a same posion for imaging.

a) Click the "Opons" on the LaBoo soware main interface to call up the "External Setup" dialog box and click

on the "Punch Bridge" tap for sengs;

b) Select "Embedded Punching" in the first pull-down menu field, then put a ck on the "Enable Bridge” check

box;

c) There is no need to select “Bridge Type” and you may leave the lower parameter fields as default (fields will

be gray out).

a) Device with built-in punching featurerequires proper setup of “Punch Bridge” sengs in Template Upload in

order to have built-in punching working accordingly;

b)In the Template sengs, click on the “BGP” to enable the “Punch Bridge” tab under the Template edit mode,

on the Device Code field: select “Embedded punching”;

c) For plate Entrance direcon, or Exit direcon: No need to set or apply if using “Embedded punching”.

d) Mold selecon (Die punch): select the correspondent Die Punch set for used with the current working

template, only one set of Punching can be used or applied in each Template. (Each CTP device can have maximum

up to 3 sets of Punching mold installaon);

a) Regularly inspects for aluminum chuds remains, clean and repair die mold if necessary to extend its life spend

b) Regularly check the air cylinder support rod for lubricaon and sealing condions

c) Replace cylinder seals every 24 months

BGP Punch Bridge is an oponal peripheral. It can be linked with a CRON CTP device for automac

registraon and plate holes punching according to template sengs. Main funcons of BGP Punch Bridge are:

Able to automac carry out plate registraon and plate holes punching according to plate specificaons used on

the CTP. Allow 4 direcons of plate media delivery depend on devices layout. And can be directly joint with a

plate processor equipment.

Punch moldcover

Die punch components (internal)

Electrical box

BGP Interface port connecon

Le-right conveyorbelts

Front-back sending rollers

6.2.2BGP Punch Bridge conneconConnect the BGP Punch Bridge communicaon cable(CAN BUS) on both the

BGP interface port connectors on the CTP device and on the BGP Punch Bridge.

2928

SIMPLE AND DIRECT 丨 STEADY 丨 MAJOR

SIMPLE AND DIRECT 丨 STEADY 丨 MAJOR

Loading...

Loading...