7.1Device internal cleaning & inspection procedures

在使用直接制版机之前,必须仔细阅读、并理解手册内容,操作应该严格遵守所有安全手则和规定流

未经许可打开或改造、及私自对制版机的硬件或者电路部分进行非法操作,都可能带来对身体的严重

Attention: Power must be turned off to ensure safety during maintenance.

Surface cleaning manners and precautions:

Important: Strongly recommended that the following maintenance should be carried out by a trained engineer or under the direction of a CRON qualified engineer.

Chapter 7: System Maintenance

For optimum performanceand productivity, regular maintenance and services are

required to be carried out on the device. The following are recommended maintenance

cycles and details to be noted (Inappropriate handling not according to

recommendation may affect device performance and even damage the

machine).Maintenance is divided into routine maintenance and regular maintenance.

The device must to be operated under standardenvironment requirement as stated

according in the 《User Manual》.

While cleaning device surface, first used a vacuum cleaner to clean dusts on the

machine casings, seams and accumulated dusts on plate loading platform.

If the indoor air is dry and clean, and the machine is often being cleaned, just use dry

cloth is wipe and remove the dust from the surface;

For thoroughly cleaning, wipe with a damp cloth mixed with mild cleanser and clean

with a damp cloth with detergent until it is cleaned and dried.

Attention: Do not spill or leak water or detergent into the device, this could causehazardous to operator or damage the machine.

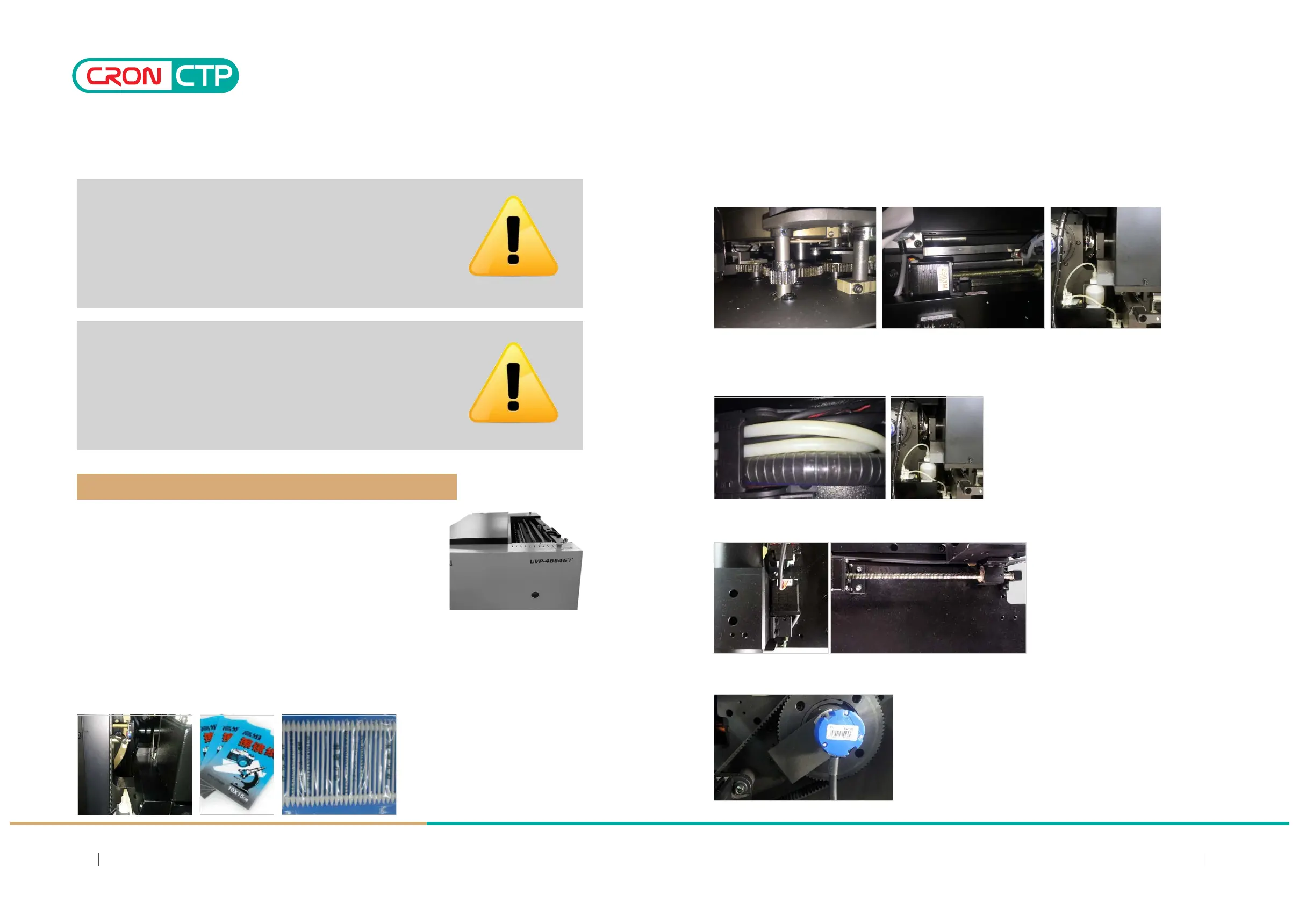

7.1.1Drum surface cleaning: After certain period of usage, plate pressing roller

(mounting roller) and drum surface will have accumulation of dusts and abrasions, that

could cause damageson plate surface, and/or affect the surface flatness during plate

loading or mounting, it is necessary to clean up both the roller and drum surface at any

time if found dusty;

a) Open the front cover of the device,you can observe the plate pressing roller

(mounting roller) and drum surface conditions and its mechanism components, please

use dry cloth to clean and wipe these area if found dusty.

7.1.2Lens cleaning: After long period of usage, even its dust removal module, front lens sections are parts that could get

dust accumulates, and could affect laser power, focus efficiencies during operation, and therefore this need regular

cleaning maintenance;

a) Remove the device’s upper right casing, notice the position of the Optical sensor and the lens. When opening, pay

attention to the cable connection of the emergency stop switch and avoid pulling.

b)Manually move the scanning platform to the most outer side, Clean the lens with special dust-free cotton bud or

glass/mirror wiping paper;

7.1.3 Regularly lubricants level check: Equipment lack of oil could easily get rusted, causing overloaded and other

mechanical problem.Please check/inspect gears structure regularly、linear bearing rail, guide raillubrication conditions and

guide rail oil container level;

7.1.4 Regularly inspection on pipelines: Aging pipelines (air flow/vacuum/pressure) can cause damage, pressure leakage

and other problems, that can affect the proper operation of the device. Please inspect the device internal pipelines for any

defectiveness, crack or fragmented.If necessary, do replace the affected pipes such as moisture depleting pipe, vacuum

pipeetc;

7.1.5 Check the scanning platform side screw, worknut lubrication and pitch cleanliness. Regularly top up lubricating oil,

such as worknut pitch worn off(loose pitch), replace the lead screw’s worknut.

7.1.6 Check the drum motor timing belt tightness and wear & tear conditions, if necessary, adjust the timing belt tightness

or replace the timing belt if found fatigue.

4140

SIMPLE AND DIRECT 丨 STEADY 丨 MAJOR

SIMPLE AND DIRECT 丨 STEADY 丨 MAJOR

Loading...

Loading...