Operating Instruction and Documentation

CSL640/641

- 53 – TES1518/E

Deviating of the use duration, according to available inspection results and empirical values

with consideration of the operating conditions, can be specified in individual cases (excerpt

from standard: ZH 1/74// DIN 20066).

• Remove all fluids in the canister. After it, seal the cover again.

• Check the oil level. Fill the tank with clean, high quality oil (32 cst) (e.g. HLP 32 LTD. OEST

Company)

• The hydraulic oil has to be changed at least once a year. To change the oil, lower the lift into

its lowest position. Empty all tanks and refill with clean oil, see chapter 3.1.

Use an ATF-Suffix hydraulic-oil (OEST Company) if the ambient temperature is less than 5

degrees centigrade. After filling, the hydraulic oil must be between the upper and lower

markings of the oil level gauge.

Remove the old oil according to the appropriate regulations.

• Check all welded joints for cracks on the automotive-lift.

If any cracks are found on the lift cease use immediately. Switch-off and secure the main

switch (lock) and call the service partner.

• Check the condition and the function of the safety ratchet.

• Check all surfaces and repair if necessary.

• Damage to external surfaces, must be immediately repaired.

If theses repairs are not made immediately, permanent damage to the powder-coated

surface may result.

Repair and clean damaged areas with an abrasive paper (grain 120). After this is complete,

use a suitable paint (observe the RAL Number).

• Check the zinc surface and repair it with a suitable tool. Use abrasive paper (grain 280).

White rust can result from moisture lying in certain areas for long periods of time. Poor

aerating can also result in rust formation.

Rust may result from mechanical damage, wear, aggressive sediments (de-icing salt, liquids)

or insufficient cleaning.

Repair and clean these areas with abrasive paper (grain 280).

After this is complete, use a suitable paint (observe the RAL Number).

• Check all the safety devices of the lift (ratchet, the optional CE-Stop, etc.)

• Check the electric cable and channels for Damage.

• Check all the covers for Damage.

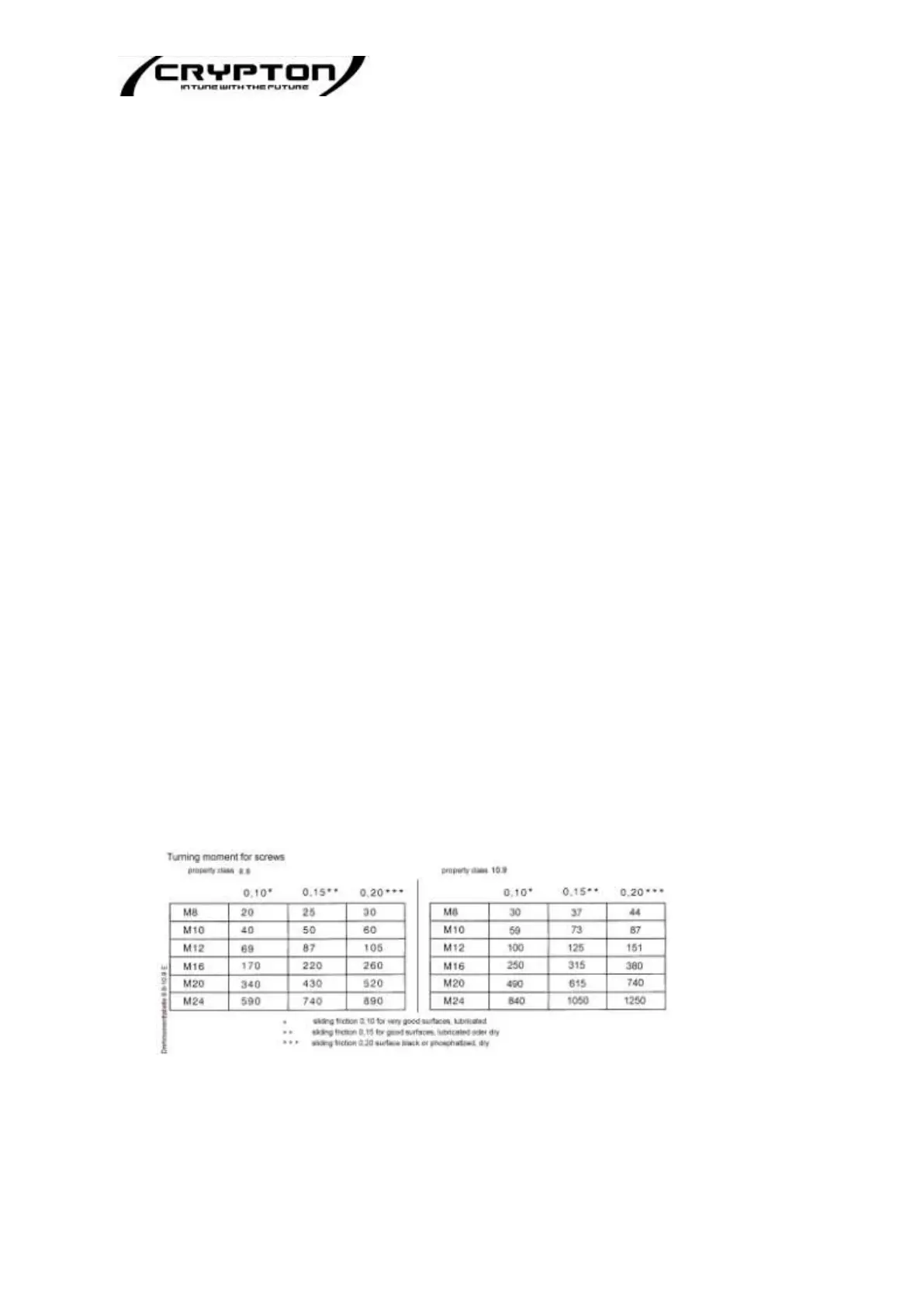

• Check that all screws and bolts are correctly torque (turning moments, see the list)

Pic 12:

The following bearing points of the LIFT should be examined by a competent person (as

described in this manual) who is able to judge the structural integrity of the lift. After

examining the lift, the bolts and bearing bushings should be lubricated as described in

this manual.

Loading...

Loading...