Operating Instruction and Documentation

CSL640/641

- 57 – TES1518/E

After having lubricated the bearings, the lift should be run up and down a few times, without a

load, so that the grease properly spreads in the bearings.

In order to maintain the grease film, the bearings should be lubricated on a regular basis. We

recommend this should be done at least once a month or, more often when the lift is being used

more intensely.

Recommended lubricants:

Grease: any regular grease

Do not use grease with Graphite or Mos 2 additives.

Spray: any regular lubricating spray

Do not use spray with a Silicon additive.

7.2 Maintenance schedule for the play detector

To be carried out at least once in a period of twelve months.

• Before beginning any maintenance work isolate the power supply. Secure the main switch

(lock it). Secure the danger area around the automotive lift and secure the lift against

unintentional lowering.

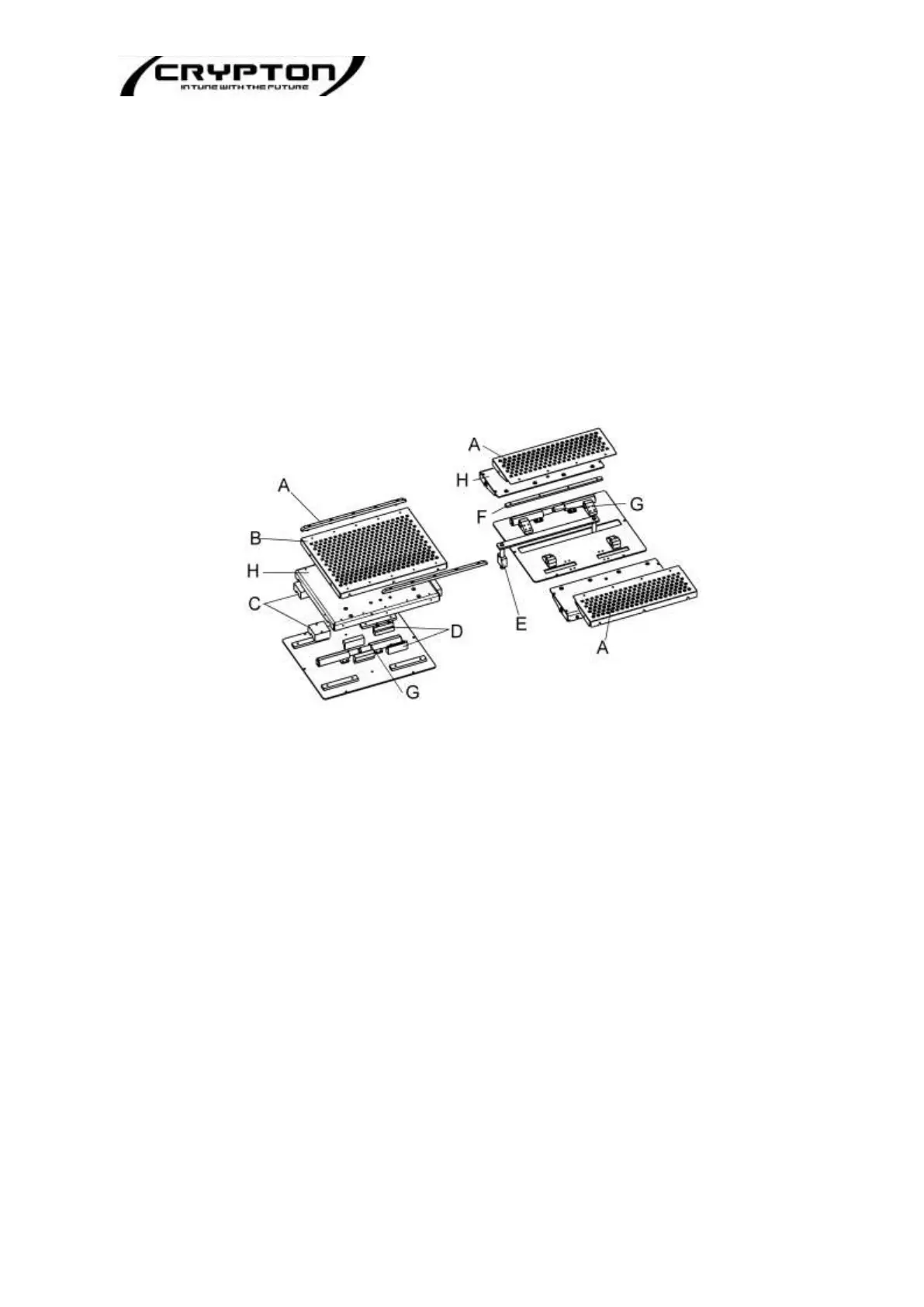

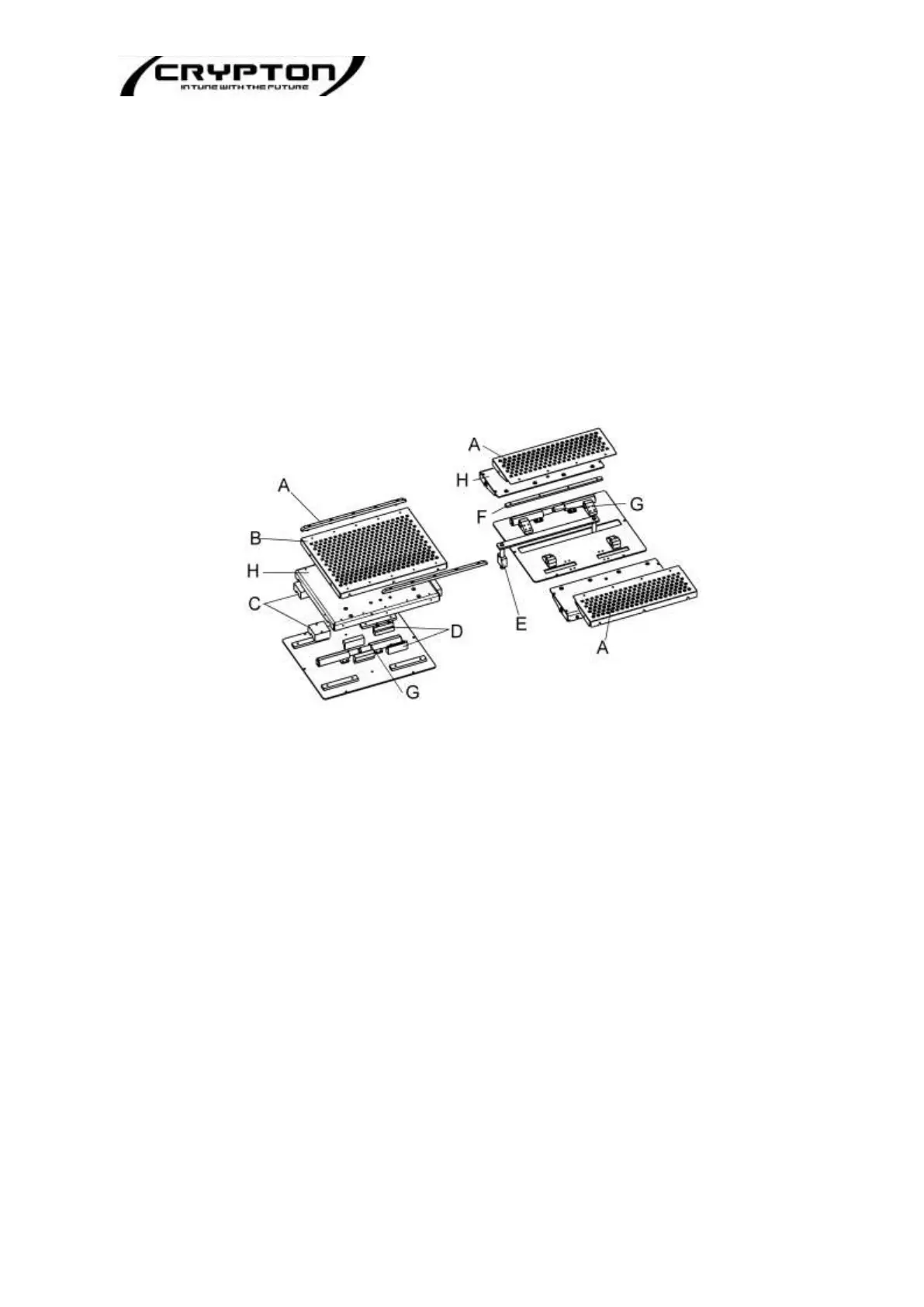

A Clean the position assistance and examine it for damages.

B Clean the plate with air pressure and examine it for damages. Afterwards lubricate with

multipurpose grease.

C First remove the plates B, H before cleaning the sliding blocks with air pressure and examine

it for damages. After lubricate with multipurpose grease.

D Clean the plate with air pressure and examine it for damages. Afterwards lubricate with

multipurpose grease.

E Check the easy-running of the lifting device.

F Clean the plate with air pressure and examine it for damages. Do not lubricate this sliding

block, otherwise the dirt remains hanging on it

G Clean the piston-rods using compressed air.

• Check the hydraulic tubes for leakage.

Life time of the hydraulic hoses.

The use duration of the hose lines should not exceed six years, including a storage time of at

the most two years.

Deviating of the use duration, according to available inspection results and empirical values

with consideration of the operating conditions, can be specified in individual cases (except

from standard: ZH 1/74// DIN 20066).

Loading...

Loading...