Engine

Inspect the clutch

•

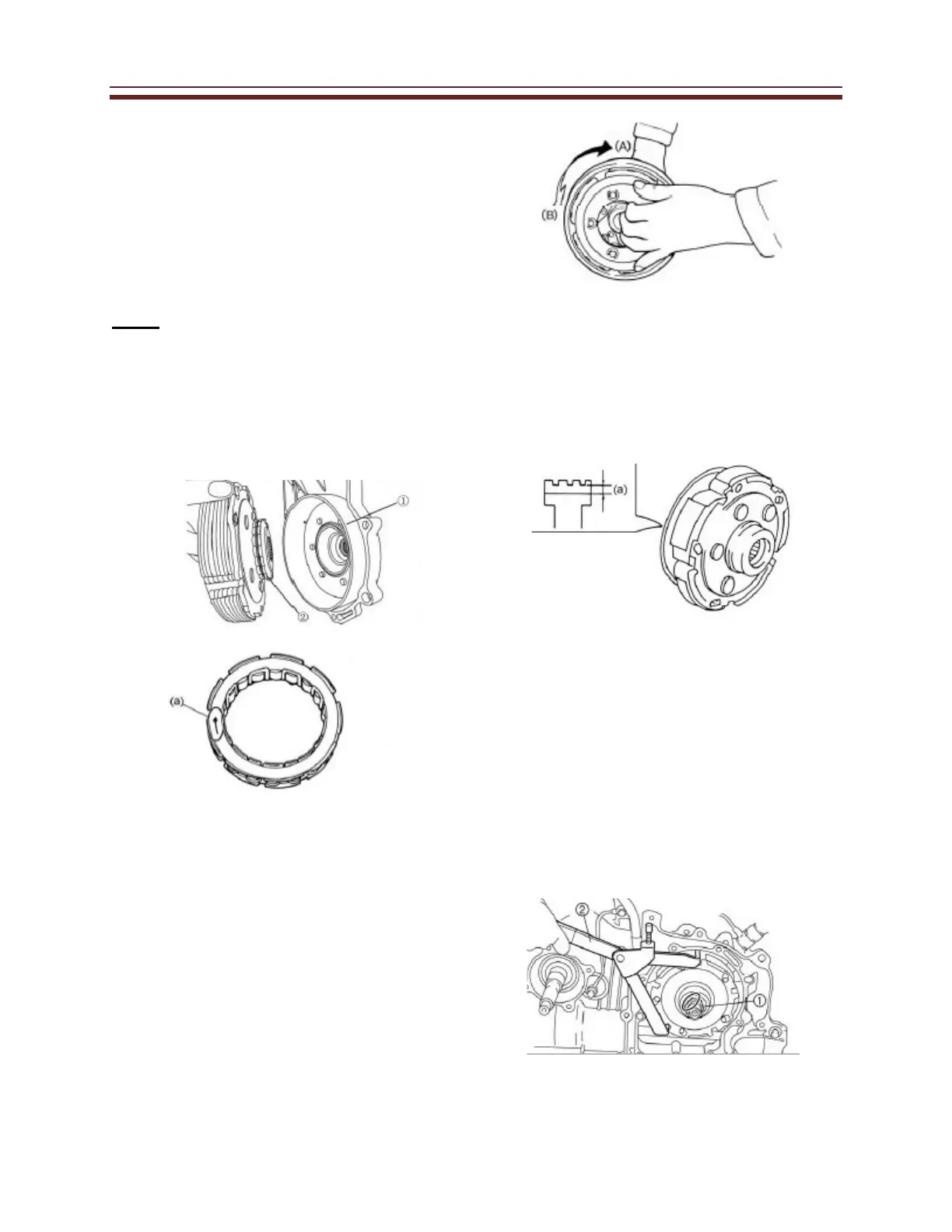

Inspect the clutch housing (1) Look

for heat damage or wear. Some

grooves are expected. A blackened

O.D. is a sign of excessive heat.

•

Inspect the one way clutch bearing

(2). Look for chaffing, wear or

damage.

Note:

If any damage is found replace the one

way clutch bearing and clutch housing

as a set. For installation the one way

clutch bearing must be installed with

the arrow facing inward toward the

housing.

Inspection of the one way clutch bearing.

•

Install the one way clutch bearing

and clutch carrier assembly to the

clutch housing and hold the clutch

carrier assembly.

•

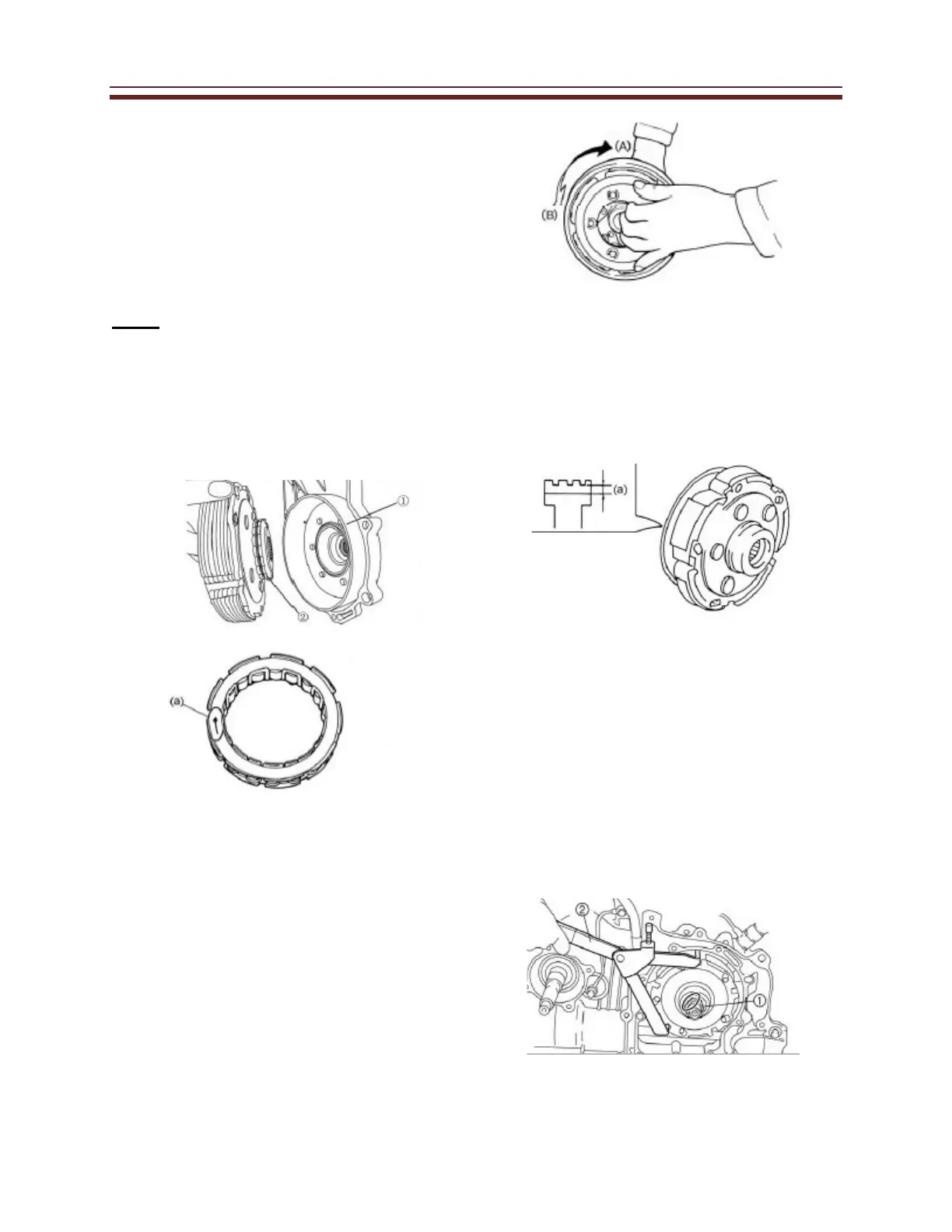

When turning the clutch housing

clockwise (A), the clutch housing

should turn freely. If it doesn’t, the

one way bearing is defective and

needs to be replaced.

Inspect the clutch shoe assembly

Look for heat damage.

Measure the clutch shoe thickness

Clutch shoe wear limit (a) 1.0 mm

Install

•

Clutch carrier assembly

•

Nut (1) 160 Nm or 118 ft lbs. Apply

high strength thread locker (Loctite

242 or equivalent.

•

Swage nut to crankshaft.

Use a universal clutch holder (2) to hold

the carrier assembly.

Lock the threads with a drift punch.

Loading...

Loading...