Cuda 2412 • 8.914-384.0 • Rev. 5/12

15

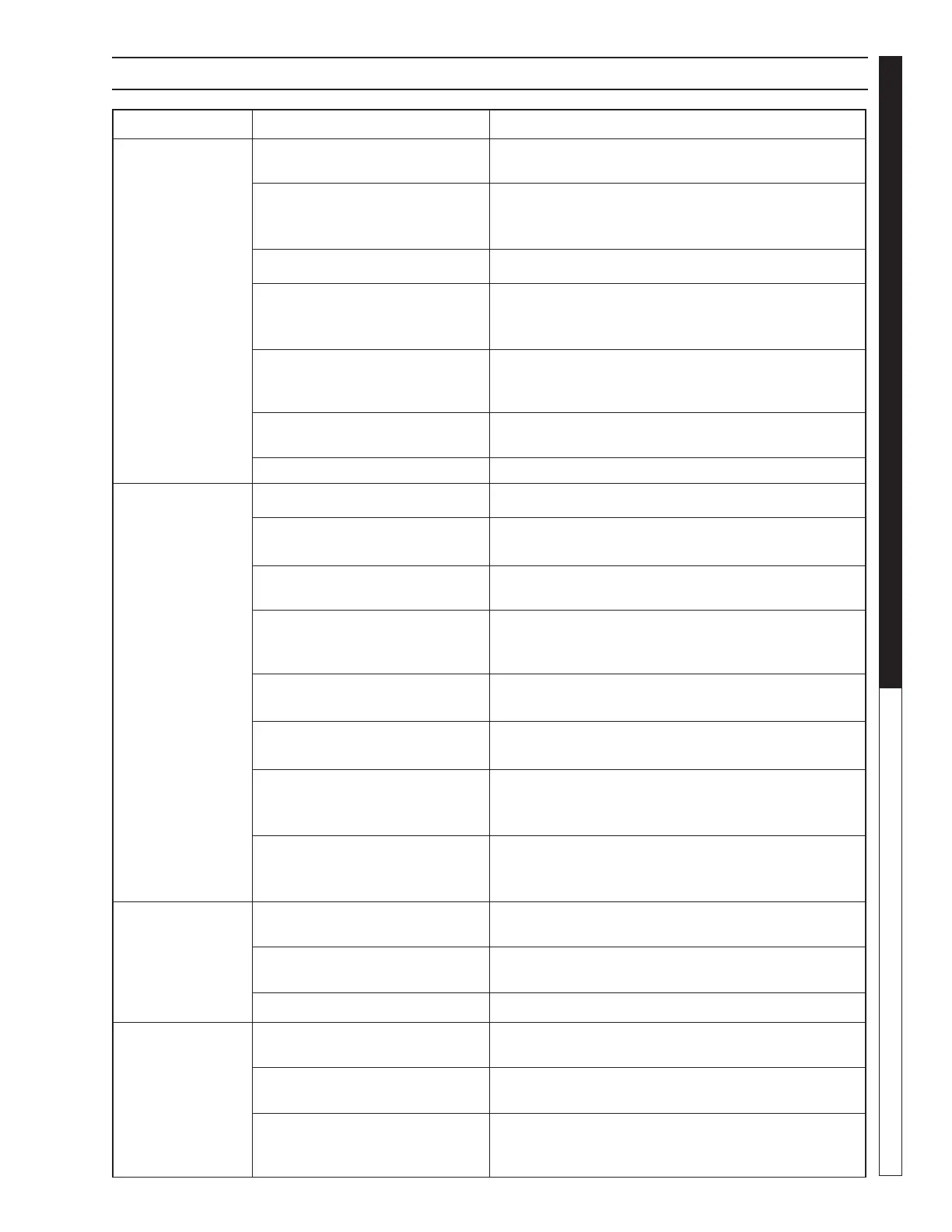

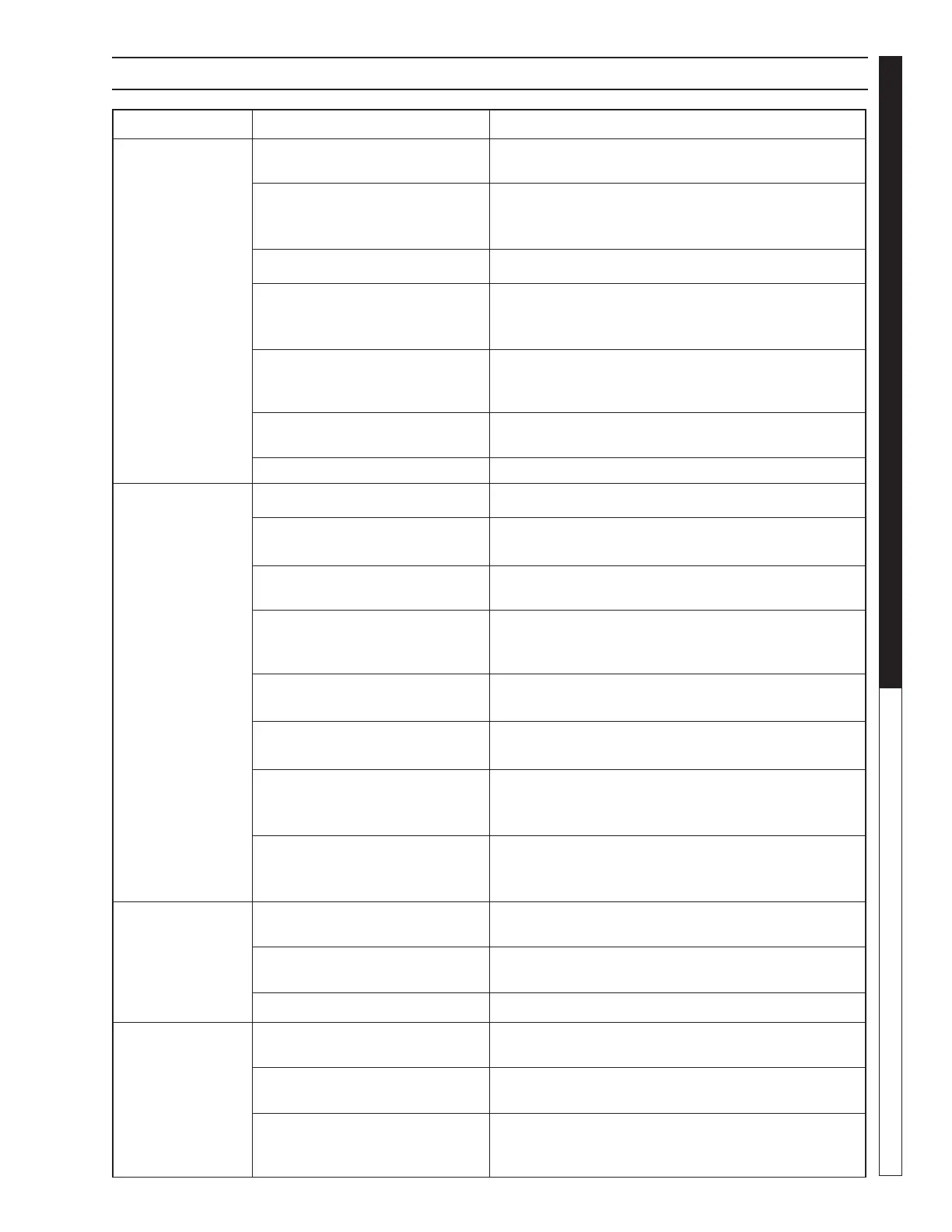

AUTOMATIC PARTS WASHER Troubleshooting Guide

SECTION 4: TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

POOR

CLEANING

PERFORMANCE

Turntable switch is OFF Verify that the turntable switch is ON

(See Turntable Switch).

Parts are obstructing each other

Check the position of parts on turntable;

position parts to allow flow of cleaning

solution around and between them.

Low water level in sump Check sump water level; add water if necessary.

Clogged or improperly aligned

spray nozzles

Check spray nozzles for obstructions and

alignment; clean and align if necessary

(See Cleaning and Aligning the Spray Nozzles).

Low detergent concentration

10-11 pH

Add 1-2 scoops of detergent and observe

cleaning performance; add 1-2 scoops

more if necessary. Measure pH.

Wash solution is not properly

heated

See wash solution is not heating

Pump is not operating properly See pump does not operate properly.

WASH

SOLUTION

NOT HEATING

Blown fuse Refer to Troubleshooting the Electrical System.

Low waterlevel in sump Check the water level in the sump; add water

if necessary (See Low Water Shut-Off).

Thermostat is incorrectly set Check thermostat setting; set to 180°

(See Adjusting the Thermostat).

Excess debris is built up around

heating element

Check for debris buildup around heating

element; clean out if necessary

(See Cleaning out the Sump).

Line voltage is too low Contact a licensed electrician to verify that the

incoming line voltage meets requirements.

Failed heater timer Test the heater timer; replace if necessary

(See Wash Cycle and Heater Timers).

Failed thermostat Test the thermostat; replace if necessary

(See Single Phase Thermostat, or

contact dealer to test a three-phase thermostat).

Failed heating element Test the heating element; replace if necessary

(See Single Heating Element, or contact

dealer to test a three-phase heating element).

FOAMING

Machine operating with cold

water

Bring water up to correct temperature

Grease, high detergent motor

oils, transmission oil, gear lubes

Do not place oil pan or transmission

pan into machine without pouring oil out of it.

Not enough detergent Add more detergent, check pH level. Use defoamer.

WHITE

POWDER

ON PARTS

Solution is old Change sump water and recharge with

fresh detergent and vapor corrosion inhibitor.

Water hardness and TDS

(totally dissolved solids)

Use a water softener and/or change your sump

water more frequently.

Large parts can dry before

solutions runs off, leaving

powdery residue

Turn heat down to approximately 140°.

Loading...

Loading...