Cuda 2412 • 8.914-384.0 • Rev. 5/12

OPERATOR’S MANUAL

AUTOMATIC PARTS WASHER

8

SECTION 2: INSTALLATION

BEFORE YOU BEGIN

To prepare to install the machine, choose an unob-

structed, level site that allows convenient access for

operators and maintenance personnel. Sources for

water and electrical power should be located near the

installation site. If your machine is equipped with

the optional power brush and hand detail brush

you must also run a compressed air line to the

installation site.

If you have any questions regarding the installation,

please contact your distributor and have the machine

identification number available for the distributor to

reference. Your machine identification tag is located

inside the front cover of this manual for detailed machine

specifications.

STEP 1: MAKE ELECTRICAL

CONNECTIONS

NOTE: All electrical installation tasks must be per-

formed by a licensed, professional electrician to ensure

safe and proper operation. The installation must comply

with the National Electric Code and all applicable state

and local codes.

The machine can only operate on the type of electri-

cal power indicated on the machine identification tag.

Read and understand the machine identification tag

to determine the electrical power requirements before

installing the machine.

STEP 2: CONNECT A

COMPRESSED-AIR LINE AND

ACCESSORIES (OPTIONAL)

This step is required for machines equipped with

the optional power brush and hand detail brush.

If your machine does not have these options,

skip the following procedure.

NOTE: To ensure proper operation and to minimize

the possibility of premature component failure, make

sure the compressed air is supplied at 75 to 90 psi.

We also recommend an in-line moisture trap and

an in-line lubricator on the main air supply line.

Refer to the documentation provided with the power

brush for more information.

Step 1:

Remove the power brush from the box, install the wire

brush in the chuck, and connect the air hose.

Step 2:

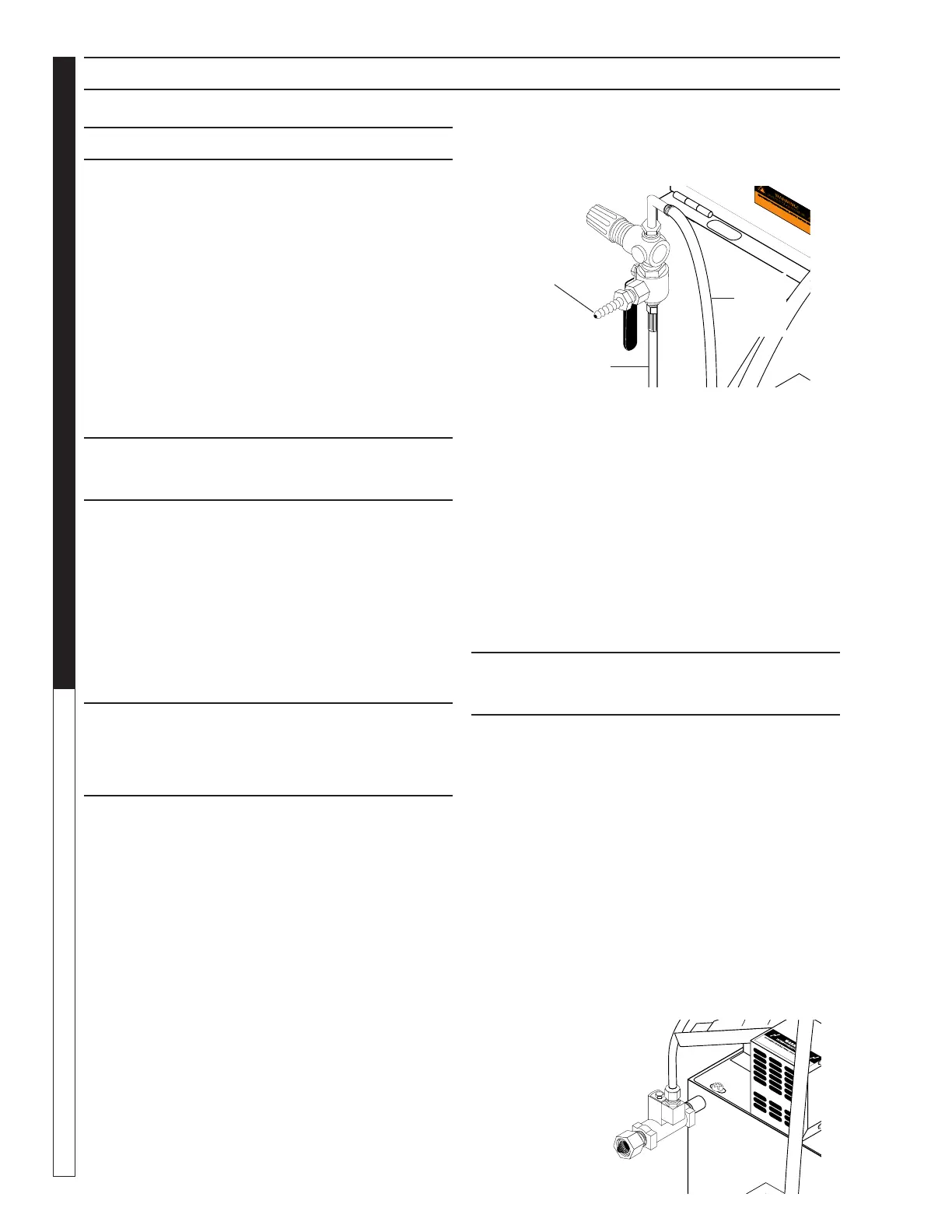

Familiarize yourself with the three-way air flow valve

(See Figure Below), then install a fitting (if necessary)

to accommodate a connection to your compressed-air

supply.

Step 3:

Connect the shop compressed-air line to the

machine.

Step 4:

Connect the hose from the power brush to the air flow

valve.

Step 5:

Hang the power brush on the bracket mounted along

the right side of the machine.

STEP 3: CONNECT A

WATER LINE

This step is required for machines equipped with the

optional automatic water fill feature. If your machine

does not have this option, skip this step.

The optional automatic water fill feature automatically

maintains the correct water level in the sump. The fea-

ture requires that you connect the machine to a dedi-

cated water supply line.

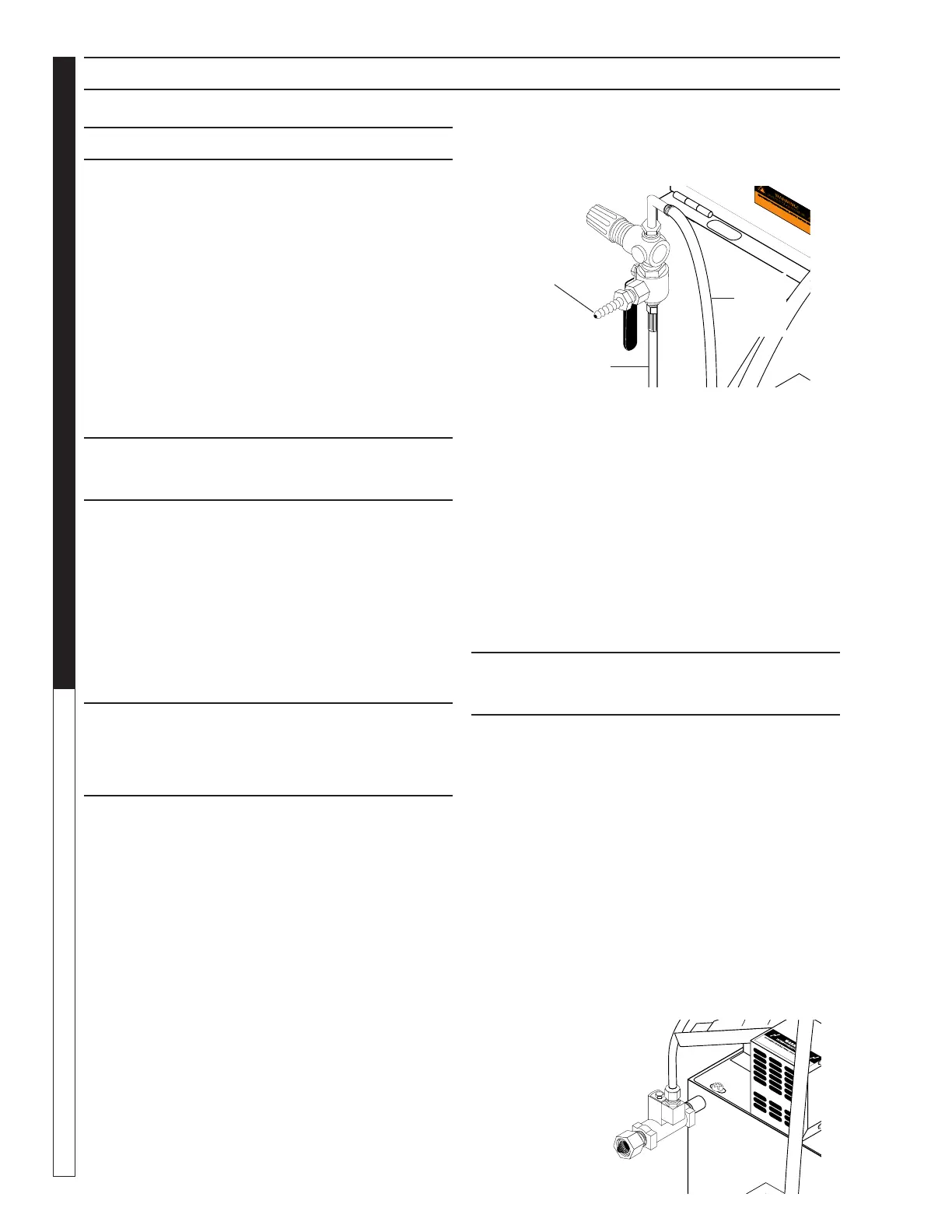

To connect the machine to a water supply line, attach a

suitable burst-proof hose to the hose connection on the

rear of the machine (See Figure Below), then connect

the hose to a nearby water spigot.

NOTE: The machine is designed for portability, and

some maintenance tasks require that you move the

machine. DO NOT make a permanent connection from

your shop water supply to the machine.

To Power Brush

Connection

Line to

Detail

Brush

Pump

Compressed

Air

Connection

Hose

Connection

(Optional)

Loading...

Loading...