Cuda 2412 • 8.914-384.0 • Rev. 5/12

AUTOMATIC PARTS WASHER Maintenance Guide

20

Cleaning out the Sump

Step 1:

Remove oil from the cleaning solution using the oil

skimmer.

Step 2:

Remove the debris screen.

Step 3:

Drain the wash solution from the sump chamber.

To drain the solution either use the sump drain

or a small submersible pump.

Step 4:

Remove sand and other debris from the bottom of the

sump chamber. To remove the debris either flush it

out through the sump drain, or vacuum it out using a

wet/dry vac. Dispose of the debris in accordance with

applicable local, state, and federal regulations.

NOTE: Take special care to ensure that the heating

element and the low-water float are free of debris.

A build up of debris around the heating element will

decrease heating performance and may cause the ele-

ment to overheat and fail. A build up of debris around

the float may cause the low water shut-off system to

malfunction (See Low Water Shutoff System)

Step 5:

Replace the debris screen.

Step 6:

Heat the wash water to operating temperature, then

add appropriate amount of factory detergent.

Step 7:

Run the machine through a 15-minute wash cycle.

REPAIRING THE MACHINE

The following procedures outline the steps necessary

to replace specific items on the machine that could

wear out or otherwise fail.

Heating Element

Required Tools and Equipment

•5/16"wrenchorsocket

•1-1/2"socketandbreakerbar

•sealingtapeorcompound

•mediumphillips-headscrewdriver

Replacement Procedure

Step 1:

Disconnect power to the machine.

Step 2:

Drain the wash solution from the sump.

SECTION 5: MAINTENANCE AND REPAIR

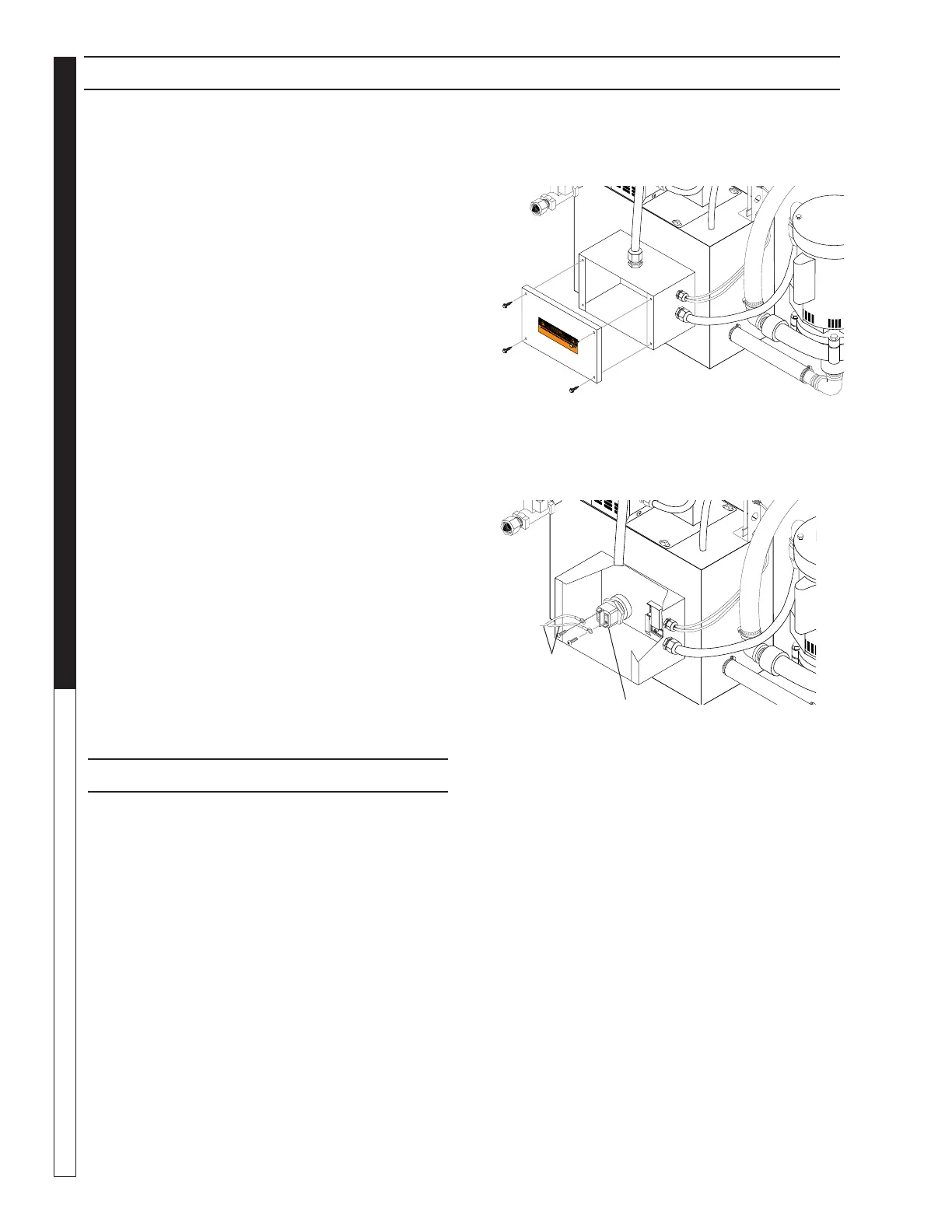

Step 3:

Remove the rear panel from the machine (four screws;

use a 5/16” wrench or socket – See Figure Below).

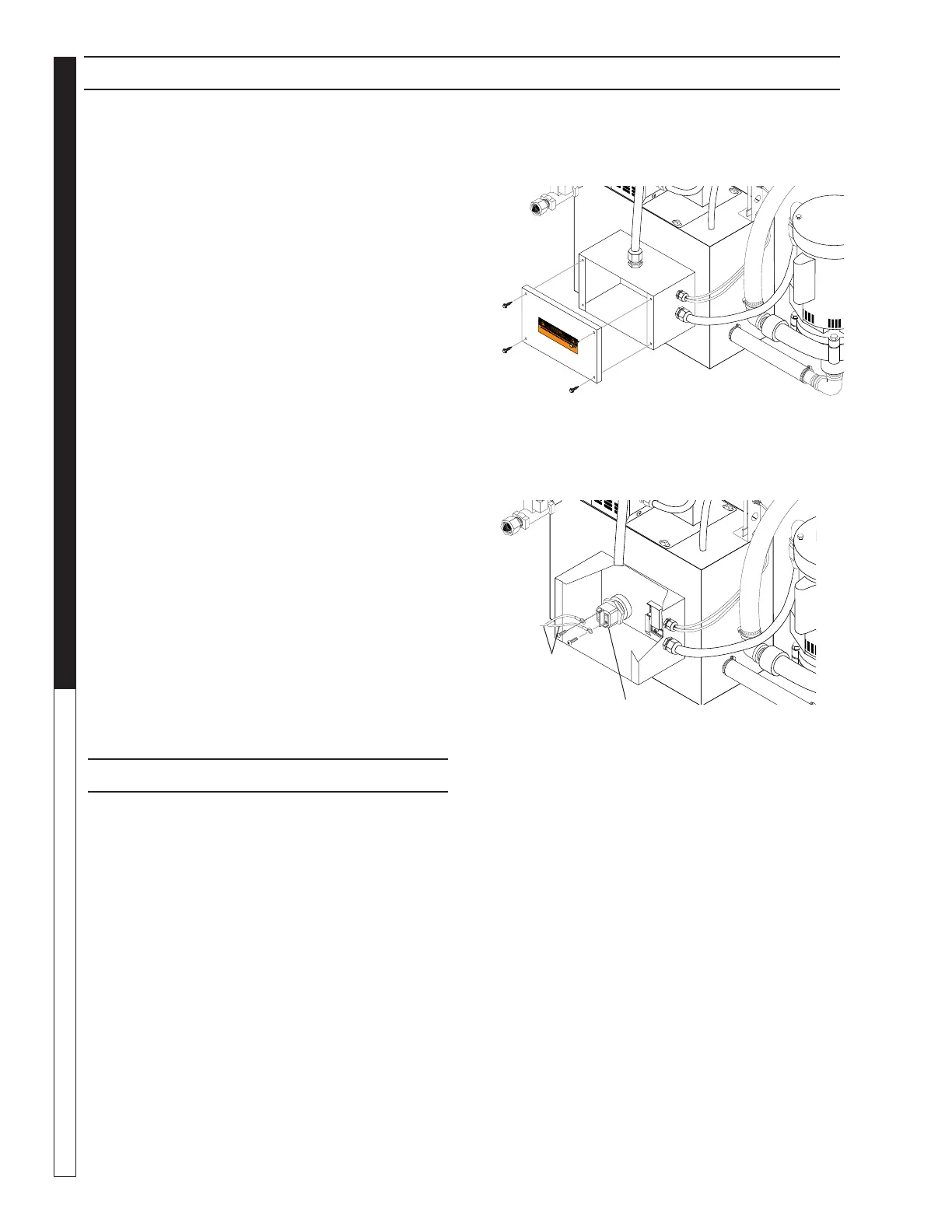

Step 4:

Detach the power leads from the heating element

(See Figure Below).

Step 5:

Using a 1-1/2" socketand breaker bar, unscrew the

heating element from the machine.

NOTE: Since the heating element is in continuous con-

tact with the cleaning solution the threads may corrode

slightly. The element may be difficult to remove. When

you install a new heating element, use sealing tape or

compound on the threads to deter corrosion, and be

sure to install the rubber gasket to prevent leakage.

Step 6:

Install the new heating element. Installation is the

reverse of removal.

Heating

Element

Power

Leads

Loading...

Loading...