RO Installation 9

Cat. No. 01023094

Non-Pressurized Product Water Storage Tank

Connect the product tubing to a bulkhead fitting at the top of the storage tank.

CAUTION! The highest point of the tubing should not be higher than four feet above the top of

the reverse osmosis modules, or the elements may be damaged.

Depending on the type of application, a level control may be required to turn the unit off when the storage tank is full.

Install the level control according to the instructions provided with the control. Refer to the wiring section in this manual for

electrical connections.

NOTICE If a repressurization pump is used, an additional level control is recommended to prevent the

pump from running dry if the storage tank is empty.

To maintain high water quality, a hydrophilic air vent filter, vacuum breaker, pop-off valve, ultraviolet lamp, and pressure

relief valve may be required.

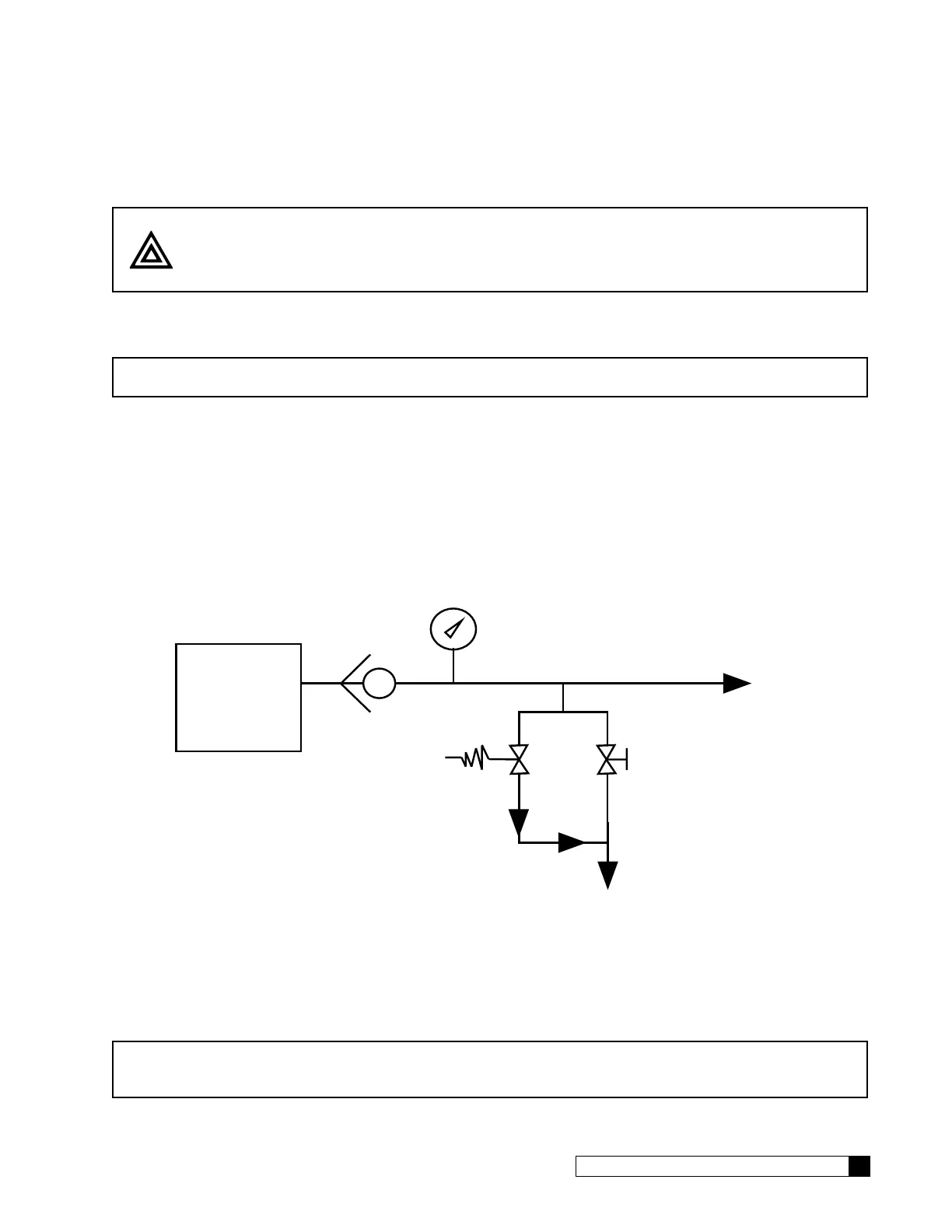

Direct Feed

If the product water is to be used directly, without storage, a few precautions are necessary to prevent damage to the

elements. Install a pressure gauge, pressure relief valve, and a normally-open (“dump”) solenoid in the product water line

as shown in Figure 5. The pressure gauge will allow the operator to monitor the product water pressure. The relief valve,

which should be set to open at 40 psig, will prevent the product water pressure from exceeding 40 psi. The dump solenoid

will relieve all pressure when the unit is off.

P/N 00440343

Reverse

Osmosis

System

Product Line

Pressure

Relief Valve

Solenoid

Valve

1

3

To Drain

To Service

Check Valve

Figure 5. Direct feed connection.

Wire the direct feed/pressurized storage solenoid valve in parallel with the motor.

NOTICE Install a check valve after these valves in case the service line remains under pressure. Product

back pressure will decrease the net pressure pushing water through the reverse osmosis ele-

ments. Therefore, the flow of product water will decrease.

Loading...

Loading...