17

M.4 While terminating R.Y.B. phase notations should be

maintained in the alternator and control panel for easy

maintenance.

M.5 Crimped cables should be connected to alternator and

control panel through cable glands.

M.6 Overheating due to loose thumbing / undersize cables

causes most of electrical failures, hence ensure that

correct size of cables and thimbles is used.

M.7 For AMF application, use 8/10 core 2.5 sq. mm armoured

copper cable for control cabling.

M.8 Typical cable sizes for 415 V application are provided

in Table M.7. The sizes given are indicative, please

refer to cable manufacturers for details.

M.9 For HT installations, kindly contact OEM’s for details

on sizing.

M.10 Care to be taken, that weights of cables should not fall

on alternator / base rail. It is recommended to support

output cables on separate structure on ground.

M.11 External wirings, when provided for remote voltage /

excitation monitoring / droop CT etc. shall be screened

sheathed type. Maximum length of such wiring shall

not exceed 5 meters.

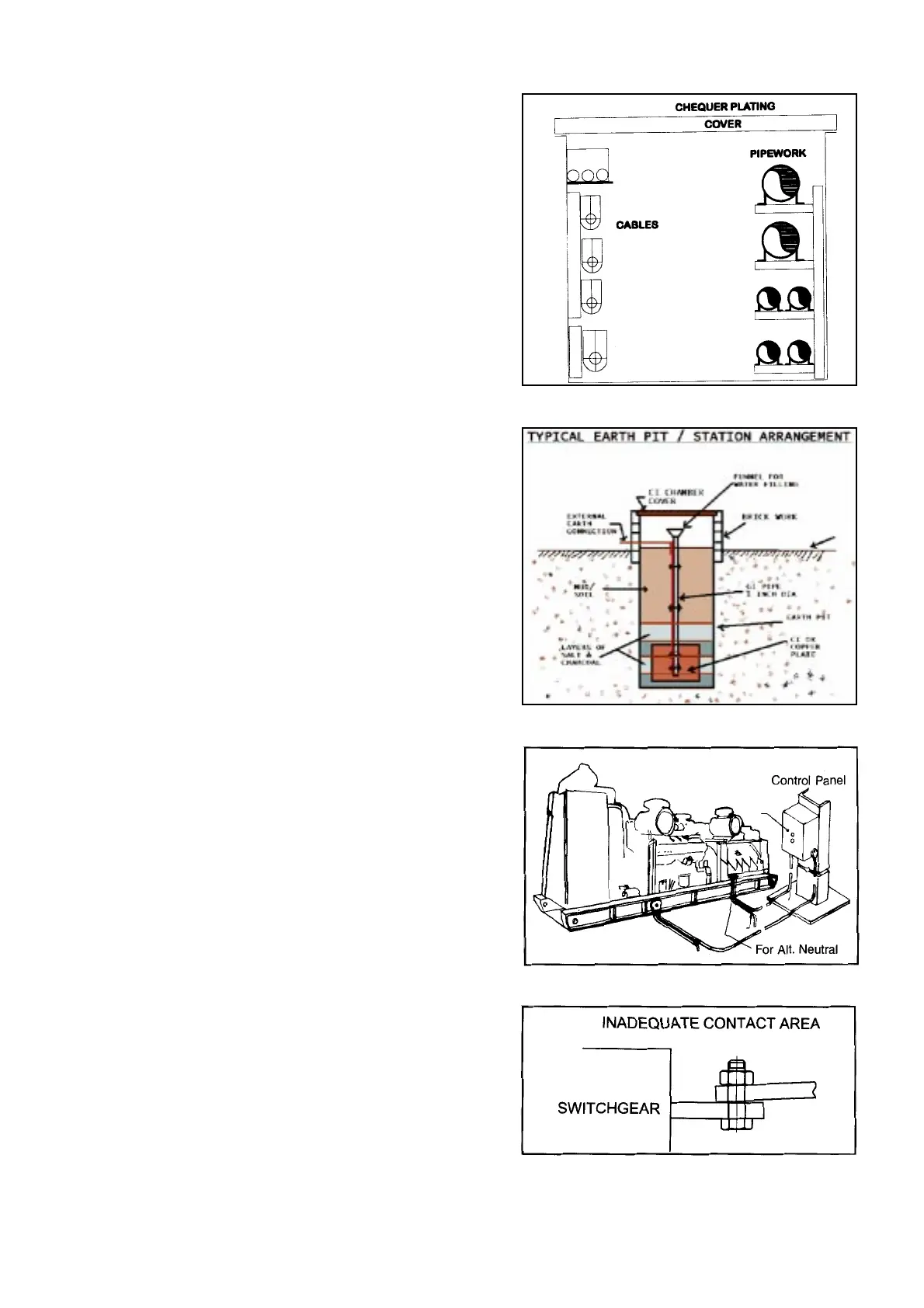

N Earthing

N.1 The generating set and all associated equipment, control

and switch gear panels must be earthed before the set

is put into operation.

N.2 4 numbers earth pits are required as per Indian Electricity

rules or local electricity board.

- 2 earthing pits for genset / control panel body

- 2 earthing pits for neutral

N.3 Copper or GI strips of suitable size may be used for

earthing. Please note that for normal soil, earth

resistance should not exceed one ohm.

Earthing should be checked with multimeter (one

probe at genset / Alternator / baserail and another

at earth strip. The resistance should be less than

1 ohm.

For gensets with AVM’s between engine / alternator

and base rail. The earthing MUST be done at the engine /

alternator and NOT at baserail.

N.4 Genset should be earthed at two distinct points through

a conductor heavy enough to carry the short circuit

current without burning out.

O. Alternator Termination Links

O.1 For proper terminations between links and switchgear

terminals, the contact area must be adequate. The

following situations should also be avoided as they lead

to creation of heat sources at the point of termination :

- Point contact arising out of improper positioning of

links with switchgear terminals (Ref. O.1).

Ref. N.4

Ref. N.2

NORMAL

FLOOR

LEVEL

Ref. O.1

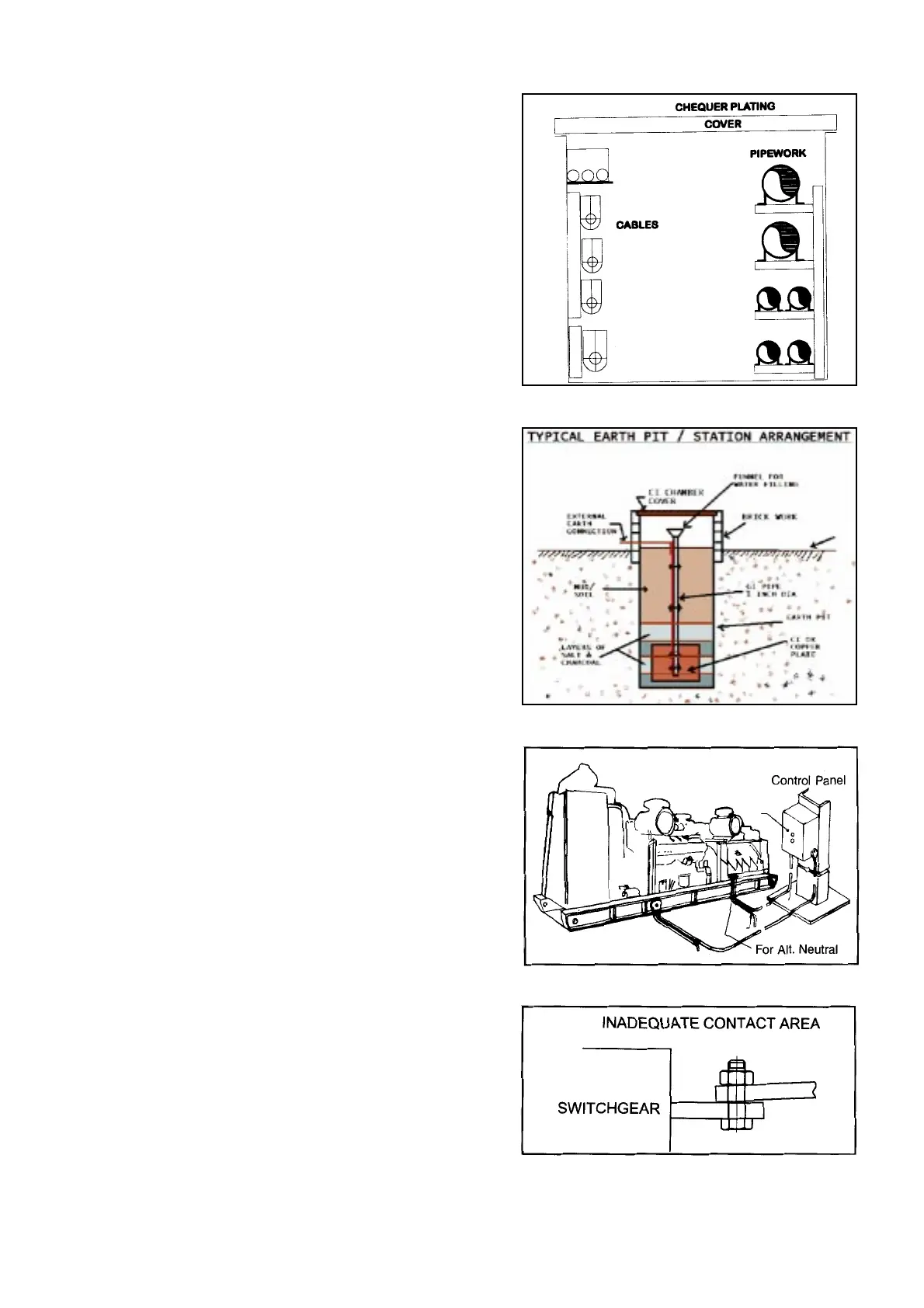

Trench Construction

Loading...

Loading...