3

GENSET INSTALLATION RECOMMENDATION

A Location

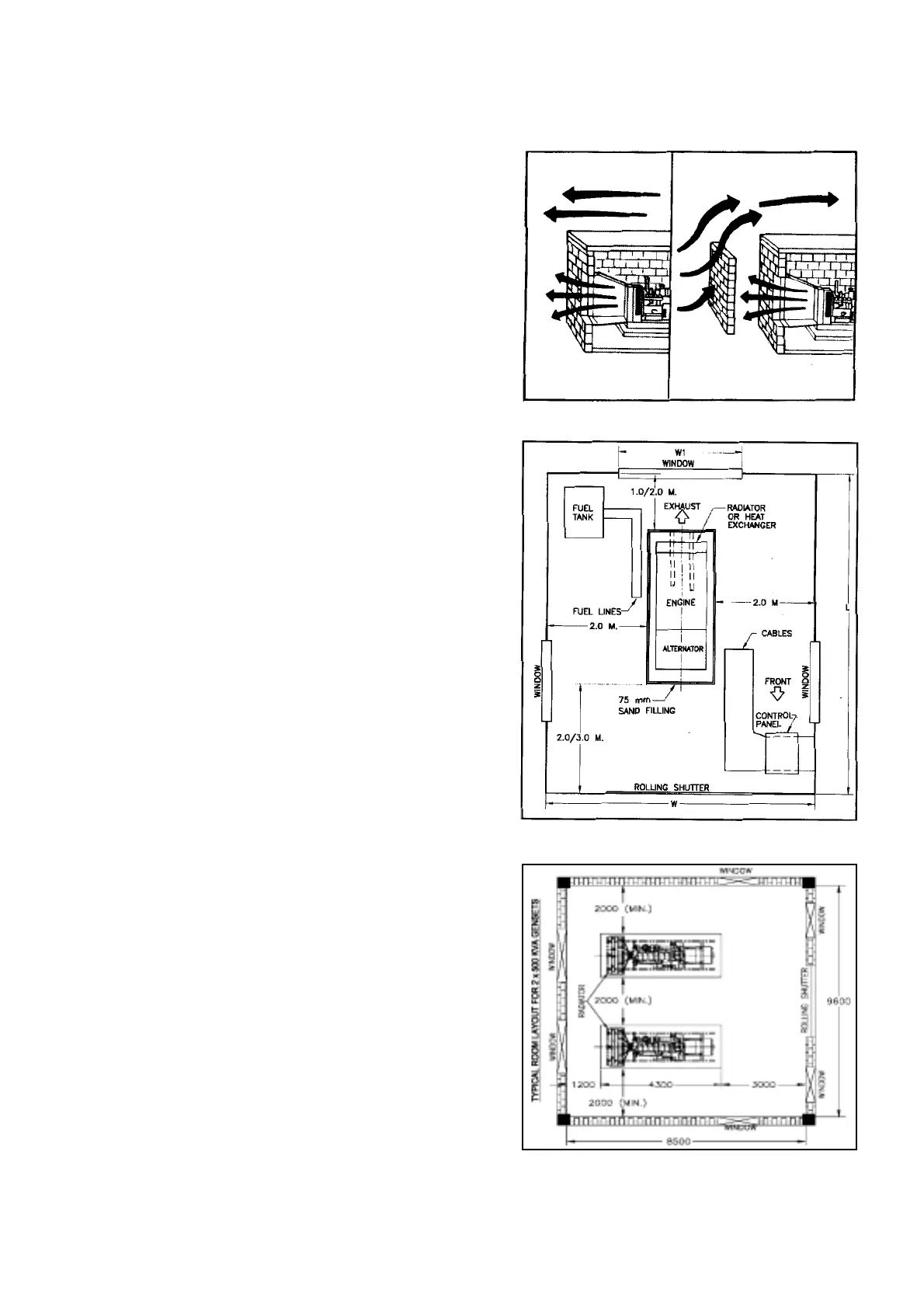

A.1 D.G. room should be located considering wind direction

and there should be no obstruction to natural wind

flow.

A.2 Position the generator set so that the prevailing wind

do not enter into the radiator / exhaust outlet. If this is

not possible, install a wind barrier. Distance of the wind

barrier from the room should be atleast three times

radiator core height.

A.3 Genset should be located away from polluted

atmosphere like acidic fumes, cement dust, stone dust

cotton fibres, furnace chemicals etc. wherever possible.

A.4 In case location is dusty or polluted, contact OEM/

Cummins. Heavy duty air cleaner is must for such

installations. Heat exchanger cooled system is

recommended for such installations as radiator gets

clogged in dusty atmosphere.

A.5 For humid / coastal atmospheric applications, anti

condensation heaters are mandatory for alternator.

A.6 Genset should be nearer to the load centre.

B Room Layout

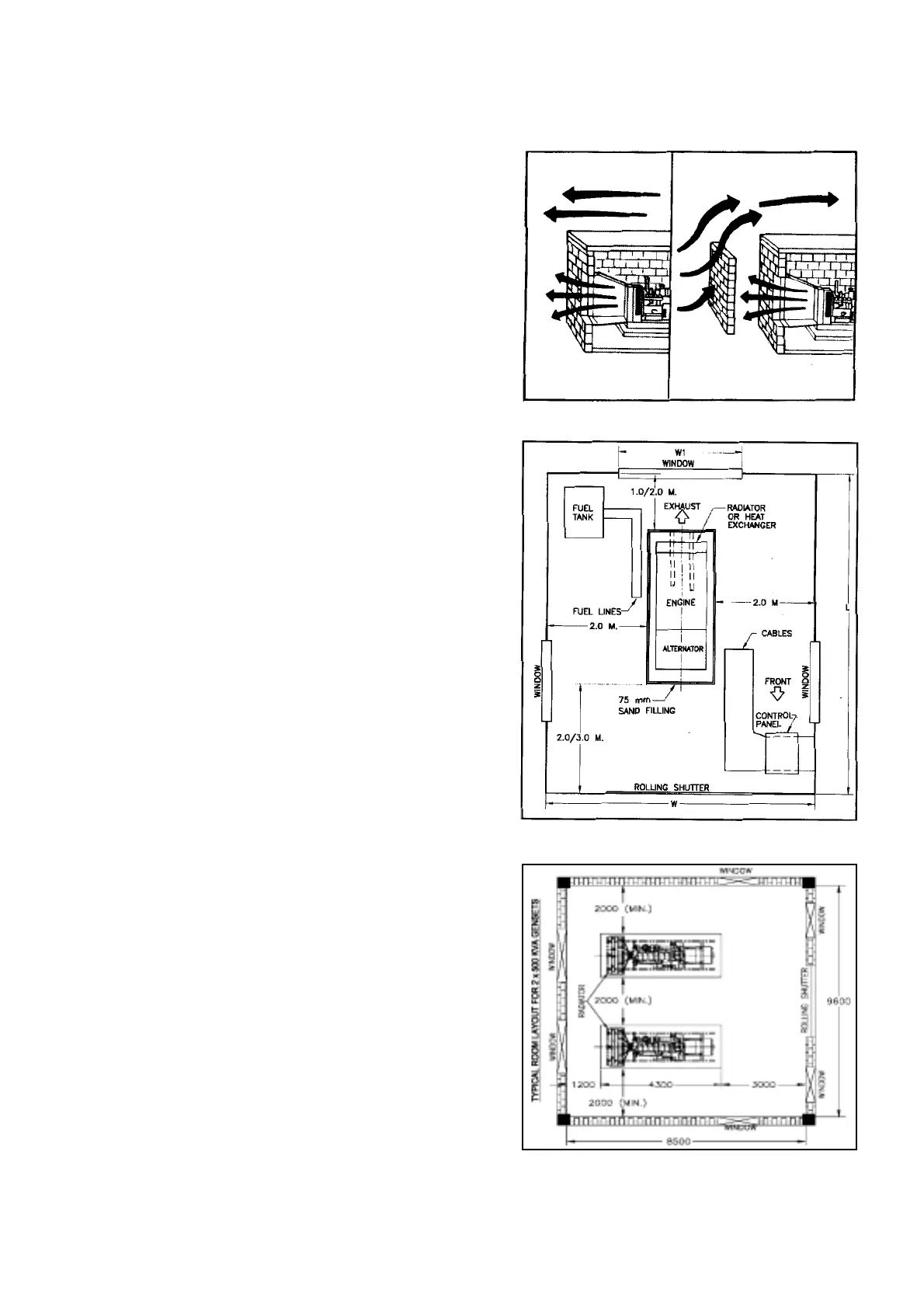

B.1 Typical 2-meters free space around genset is

recommended for proper heat dissipation and ease of

service. However, to avoid hot air recirculation radiator

cooled engines should have minimum possible space

in the front. Minimum 1.5 meter free space is a must

for 100 KVA and bigger gensets, for smaller gensets it

should be 1 meter.

Room layout is important for :

- Serviceability

- Ventilation

- Ease in operation

- Genset room aesthetics

Please refer Table-1 for typical room sizes.

B.2 In case of multiple sets provide minimum 2 meters

clearance between gensets.

B.3 While making room layout provision should be made

for :

- Cables

- Fuel lines

- Breather vent

- Coolant / lub oil drain

- Raw water lines

- Oil / spares storage

B.4 Future expansion plans should be considered while

deciding room size.

Ref. A.2

Ref. B.1

Ref. B.2

Loading...

Loading...