18

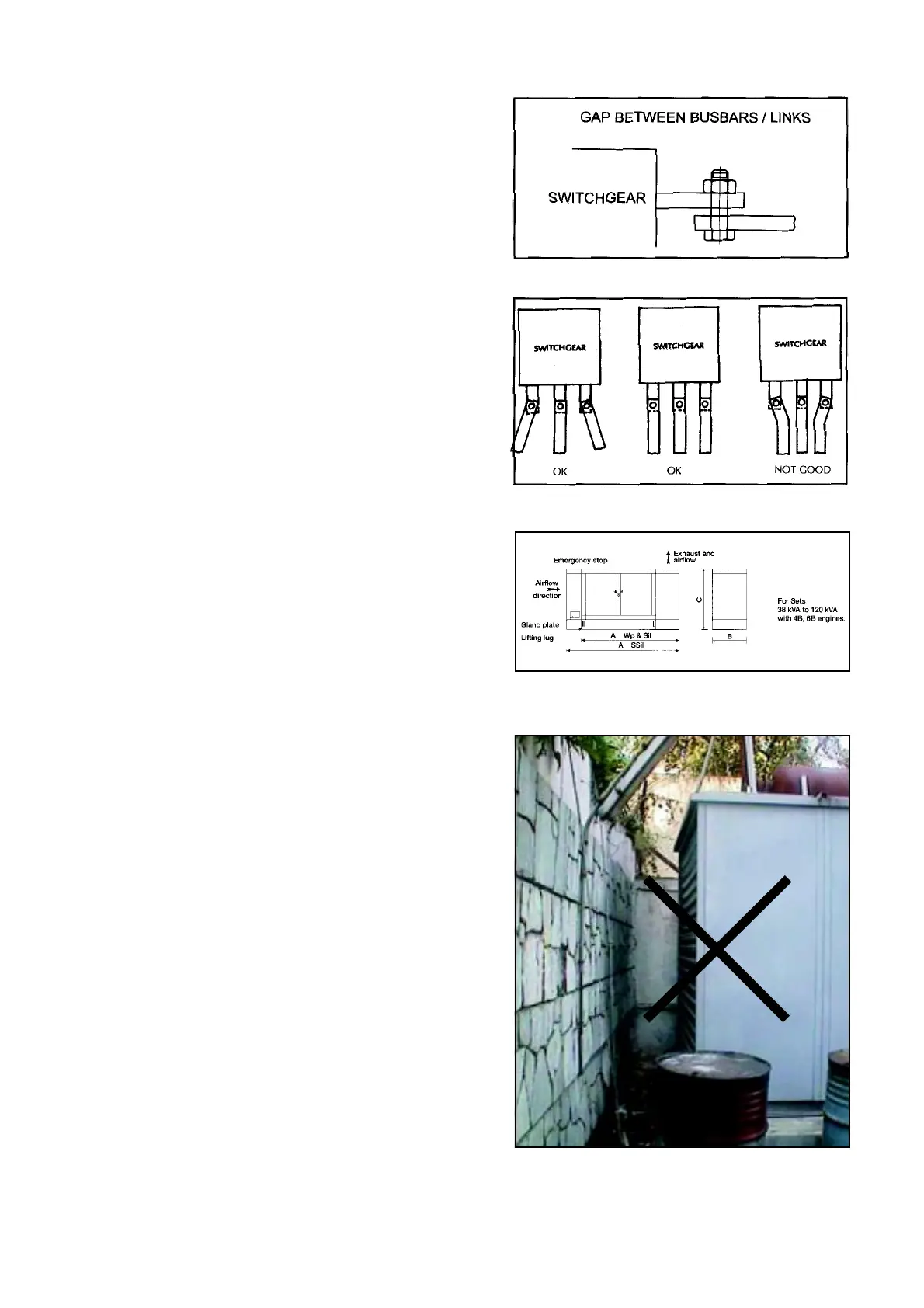

Ref. P.3

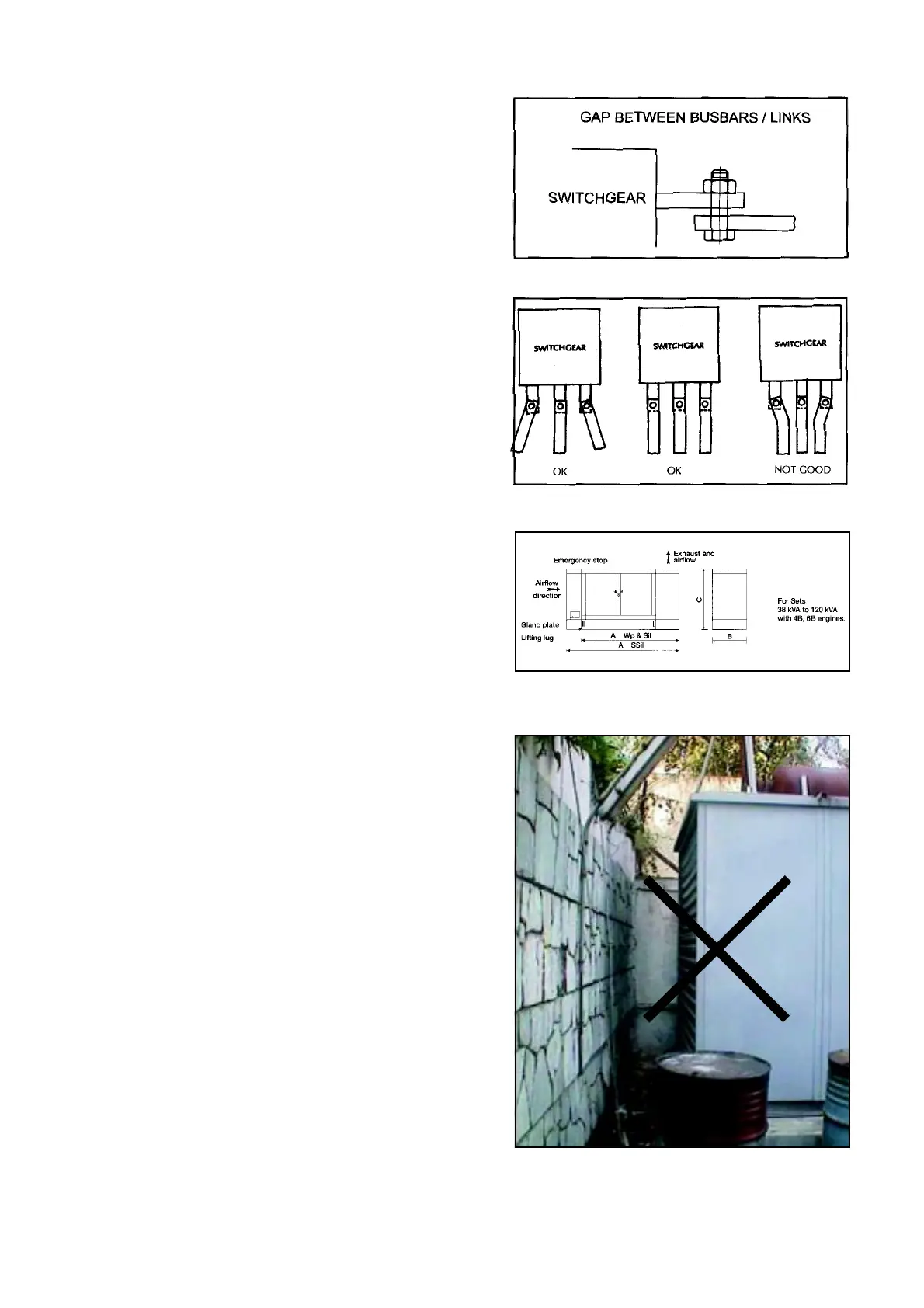

Ref. O.2

Ref. O.3

O.2 Gaps between busbars / links and terminals being

remedied by connecting bolt / stud (Ref. O.2). In such

cases the bolt will carry the load current. Normally these

bolts / studs are made of MS and hence are not

designed to carry currents.

O.3 Adequate clearance between busbars / links at terminals

should be maintained (IS:4232 may be referred to for

guidelines).

Ref. O.3 ranks the quality of different configurations.

Improper termination will lead to local heat generation

which may lead to failure.

P Genset with Acoustic Enclosure

Installation

P.1 Acoustic enclosures are supplied with built in AVMs.

As such genset can be installed directly on the leveled

surface.

P.2 Exhaust piping outlet should not be turned towards

window / ventilator of home or occupied building. Ensure

provision of rain cap.

P.3 The acoustic enclosure placement should be such that

there is no restriction in front of air inlet and outlet from

canopy.

Service Accessibility

P.4 Genset / Engine control panel should be visible from

outside the enclosure.

P.5 A / B / C check on engine / alternator (filter replacement

and tappet setting) should be possible without

dismantling acoustic enclosure.

P.6 For major repairs / overhaul, it may be required to

dismantle the acoustic enclosure.

P.7 Sufficient space should be available around the genset

for inspection and service.

General Design Guidelines

P.8 To avoid re-circulation of hot air, durable sealing between

radiator and canopy is must.

P.9 Sufficient capacity ventilation fans are required if radiator

fan flow is not sufficient. Please note that the fan flows

given in Table-1 are for open room installation. Fan flows

Typical Acoustic Enclosure Layout

Loading...

Loading...