5

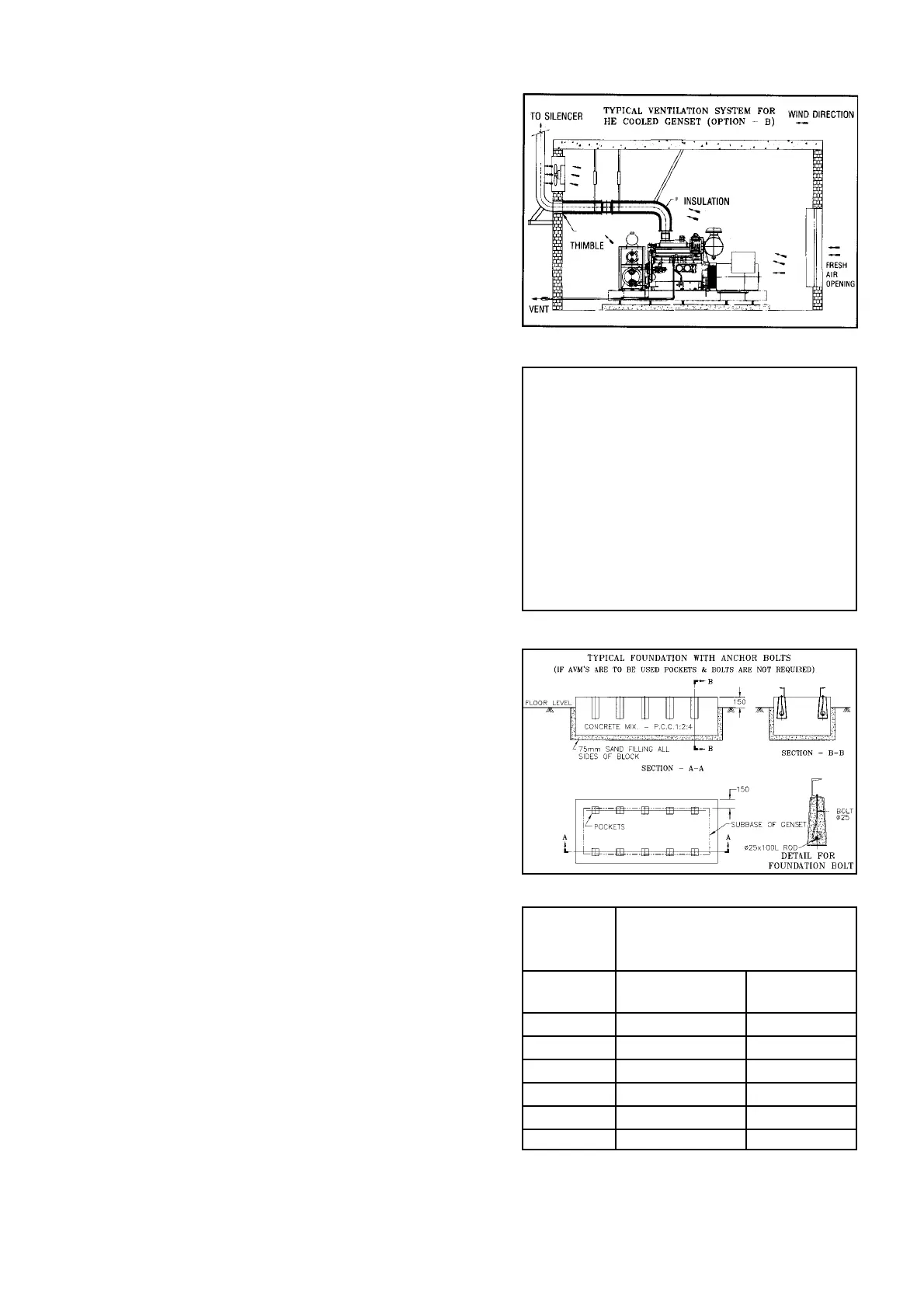

In both the cases care should be taken to avoid re-

circulation of hot air.

In some cases, it may also be achieved by proper

natural ventilation.

C.6 For basement installations, supply of fresh air and forced

ventilation through air ducts is required to remove heat.

C.7 Please refer to Table 1 for values of air required and

fan flows for various gensets rated at 1500 rpm. Values

mentioned in table are with lagged exhaust piping in the

room and silencer fitted outside the room.

C.8 Maximum allowed temperature rise above ambient

in genset room / enclosure is :

Max. ambient Allowable temp. rise

Upto 40

o

C10

o

C

Above 40

o

C5

o

C

Please note that appropriate deration may be applicable

considering altitude and temperature for a particular engine/

alternator model.

For higher ambient temperature, it is suggested to use

ambieter (air handling system with cooler) to reduce genset

room temperature and ventilation air requirement.

C.9 Field Check for Proper Ventilation

1. Run the engine on full load / typical load for about

1 hour so that temperature in the genset room gets

stabilised.

2. Measure the ambient air temperature (ambient

temperature should be measured outside the genset

room in shade).

3. Measure the temperature inside the genset room.

Genset room temperature should be measured near

air cleaner inlet of engine.

4. Calculate temperature difference between genset room

temperature and ambient i.e. delta T.

Sometimes to ensure proper ventilation, it may be

necessary to measure actual airflow by anemometer.

C.10 Suitable deration is required in case of ducting of alternator

air inlet and outlet. For details please refer to OEM.

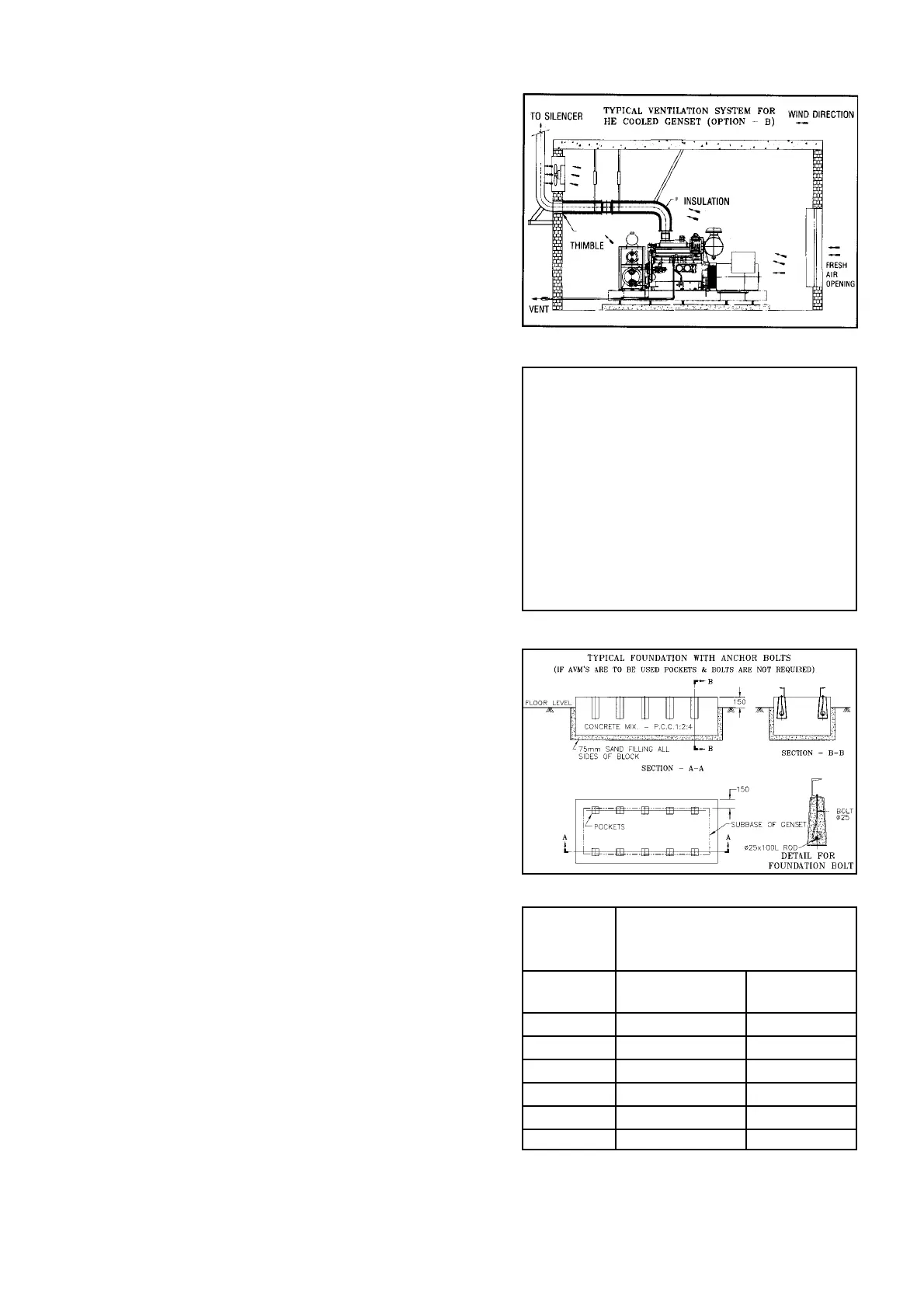

D Foundation

D.1 Do not install genset on loose sand or clay.

D.2 Foundation should be designed considering safe bearing

capacity of soil. Vibration isolators (AVMs) reduce

generator set vibration and noise transmission to the

surrounding structure. Hence they are recommended,

however they are not mandatory.

D.3 If foundation is with anchor bolts, higher depths of

foundation is required as compared to mounting on AVMs.

Please refer attached table for depths of PCC (Plain

Cement Concrete) for typical soil condition, however

structural engineer should be consulted to verify the data

depending upon soil condition. If RCC (Reinforced Cement

Concrete) is used the depth of foundation can be reduced

as per recommendation of structural / civil engineer.

Pockets (150 mm x 150 mm) are required if foundation

bolts are to be used. For AVMs plain foundation is

adequate. Static and dynamic load data for foundation

design can be furnished on request.

Ref. D.3

Typical Depth of PCC Foundation

(For soil bearing capacity

5000 kg/m 2 i.e. 1025 lb./ft.2 )

Model Without With

KVA AVM (mm) AVM (mm)

750-2000 1500 600

625 1200 400

320-500 1200 400

200-320 1000 400

Upto 200 900 400

82.5 450 200

Ref. C.5 (B)

Engine room ventilation can be estimated by the following

formulas :

H

V (cfm) = ————————— + Engine Combustion Air

0.070 x 0.24 x ∆ T

or

H

V (m

3

/min) = ————————— + Engine Combustion Air

1.099 x 0.017 x ∆ T

V = Ventilating air (cfm) (m

3

/min).

H = Heat radiation (Btu/min) (kW).

∆ T = Permissible temperature rise in engine room

(

o

F) (

o

C).

Density of air at 100

o

F = 0.070 lb/cu ft (1.099 kg/m

3

).

Specific heat of air = 0.24 btu/

o

F (0.017 kW/

o

C).

Assuming 38

o

C (100

o

F) ambient air temperture.

Ref. C.7

Ref. D.3

Loading...

Loading...