7

F.3 If fibrous conditions exist then care should be taken to

prevent the fibers from getting sucked into the air cleaner.

Provide air ducts, air curtains, nets etc. In such cases

consult OEM / Cummins.

F.4 Care to be taken, that no such fibre element shall enter/

block the air flow of alternator.

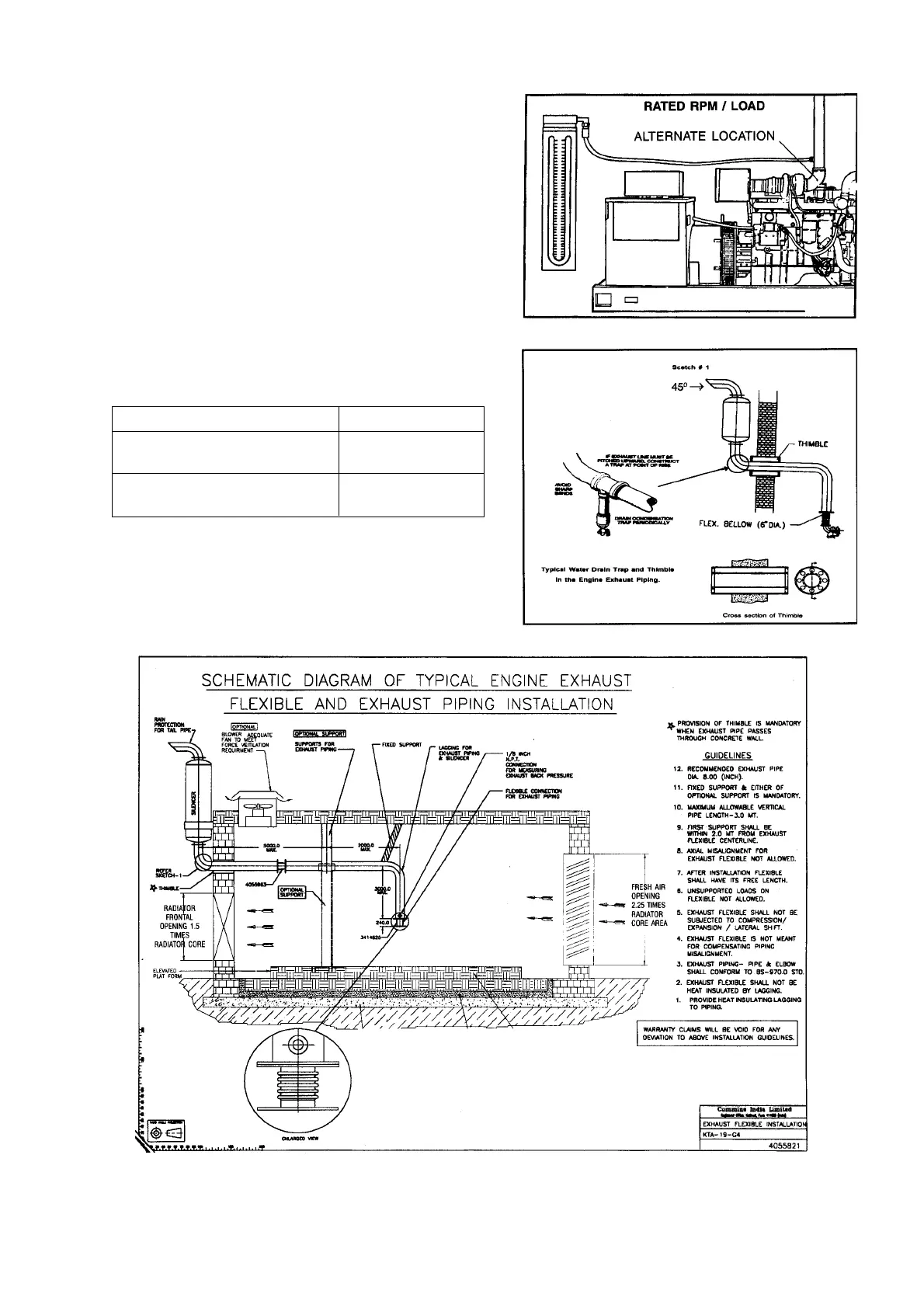

G. Exhaust System

G.1 Exhaust system should create minimum back pressure.

Higher back pressure leads to :

- Lower fuel economy

- High exhaust temperatures and related failures

- Poor performance of the engine

- Less durability of the engine

G.2 Limits for exhaust back pressure

Model mm (Inches) of Hg

KTA50G8/QSK60/S Series/ 51 (2)

Gas Engines

KTA50G3/KT2300G/VTA28/K19/ 76 (3)

NT/N14/B/C/X Series

For new installations it is recommended to have back

pressure lower by 12 mm (0.5”) of Hg than limit.

G.3 Use of thimble is must while passing the pipe through

concrete wall. The clearance around the pipe in wall is

must for free movement and expansion / contraction of

piping.

Ref. G.2

Ref. G.3

Ref. G.5

Loading...

Loading...