8

G.4 Exhaust piping inside the genset room should be lagged

along with aluminum sheet cladding to avoid heat input to

the room. Typical thickness of lagging is 50 mm.

G.5 Exhaust flexible shall have its free length when it

is installed. Recommended piping arrangement

with support locations for KTA19G4 engine is shown

in G-5.

For K6 and bigger engines 2 flexible bellows per bank

and residential silencer is supplied as standard scope.

For engines upto KTA1150 only one bellow is supplied.

However, if exhaust pipe length is more than 7 m then

additional bellow / provision for expansion should be

provided.

G.6 It is recommended to use ‘Schedule B’ MS pipes and

long bend elbows. Please refer Table 1 for pipe sizes.

If number of bends are more than 4 or pipe length

is more than 10 meters than contact OEM /

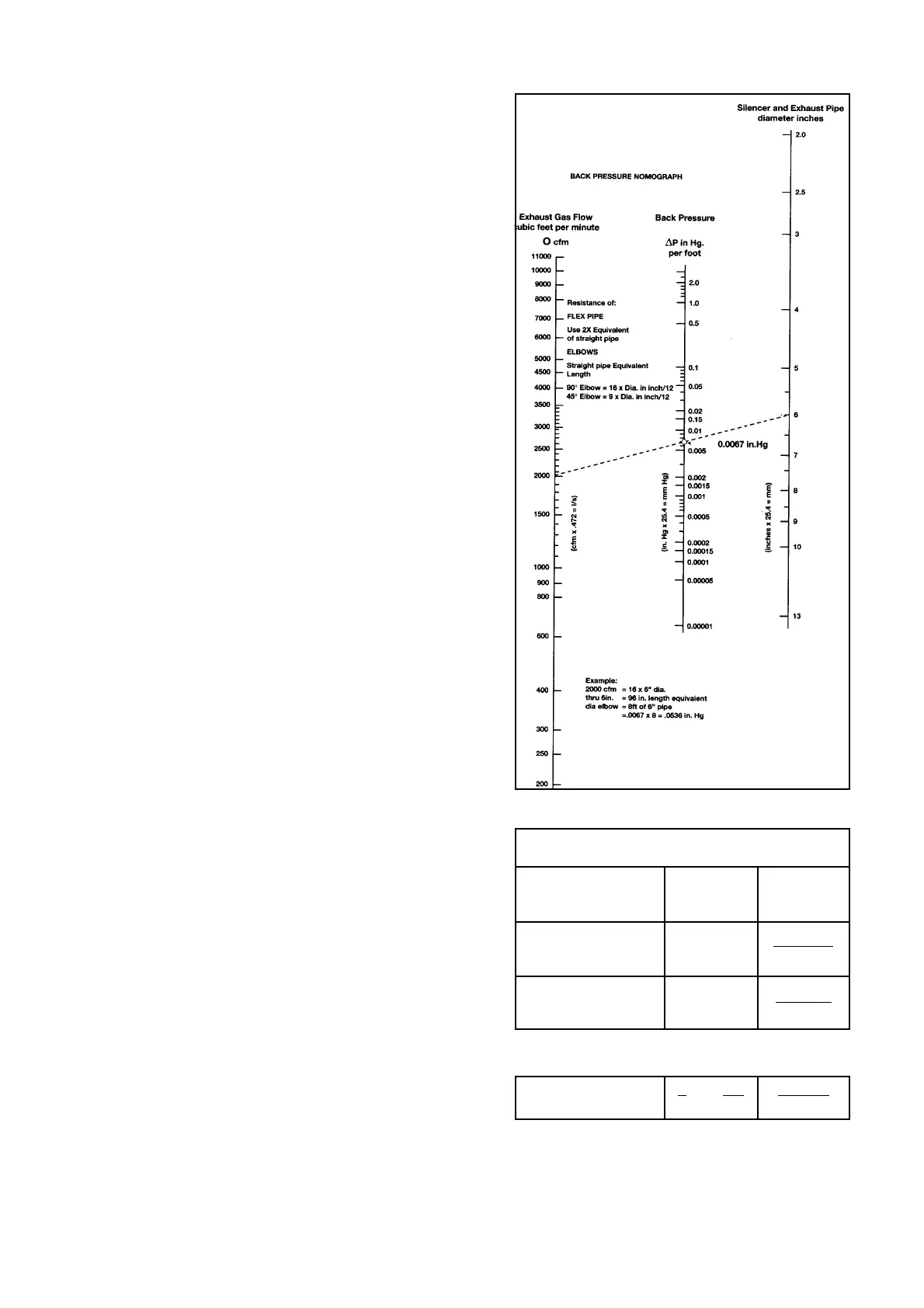

Cummins for piping arrangement. Please refer back

pressure nomograph for calculating exhaust piping

back pressure, if required.

G.7 The exhaust outlet should be in the direction of prevailing

winds and should not allow exhaust gases to enter air

inlet / windows etc.

G.8 There should be rain trap to avoid rain water entry. If rain

cap is used the distance between exhaust pipe and rain

cap should be higher than diameter of pipe. It is also

recommended that horizontal run of exhaust piping should

slope downwards away from engine to the condensate

trap. Silencer should be installed with drain plug at bottom.

Above covers general guidelines for exhaust system

installation. For model-wise details regarding installation

and scope of supply, please refer to service information

bulletin SIB 00-2, available with Cummins network.

G.9 Optimum Silencer Location : Location of the silencer in

exhaust system has very definite influence on both

silencing and back pressure imposed on the system. The

preferred silencer locations are given in the Table G.9,

where L is length of the total exhaust system measured

from exhaust manifold in meters. Please note that locating

the silencer as per optimum silencer location is not

mandatory. For high rise buildings suitable arrangements

may have to be provided in consultation with acoustic

engineer.

G.10 Exhaust stack height : In order to dispose exhaust

above building height, minimum exhaust stack height

should be,

H = h + 0.2 x √ KVA

Where H = height of exhaust stack

h = height of building.

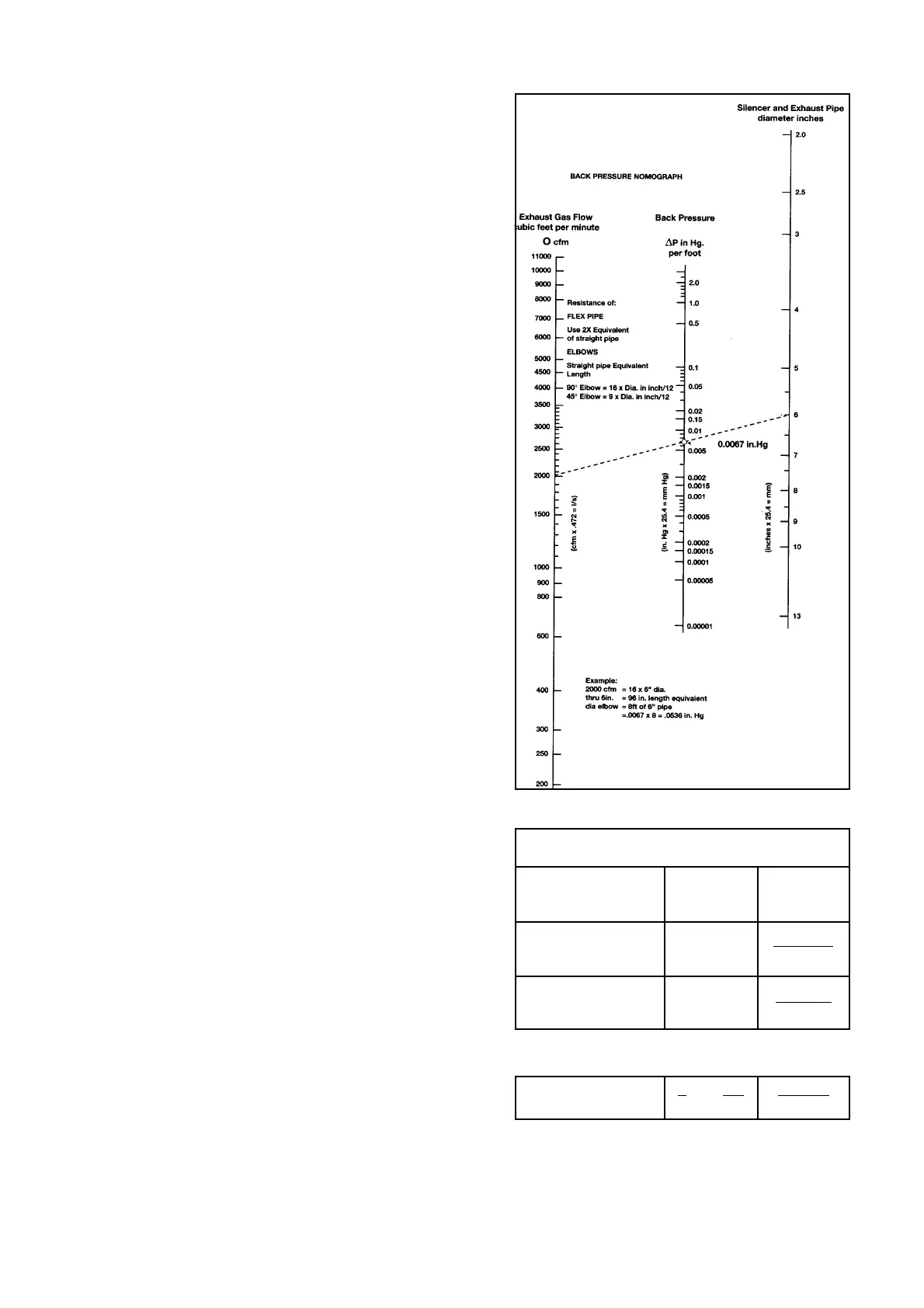

Ref. G.9

Optimum Location of Silencer (in meters)

In-line ‘V’ Engine

Engine Engine

Best 2 L/5 4 L – 1.5

5

Second best 4 L/5 2 L - 4.5

5

Worst Location of Silencer

Lor3 L 3 L - 10

55 5

Ref. G.6

Loading...

Loading...