9

0-5 ft.(0-1.5 m)

G11 Care should be taken to ensure that no carbon particles emitted due to exhaust leakage enters and deposits on

alternator windings and open connections

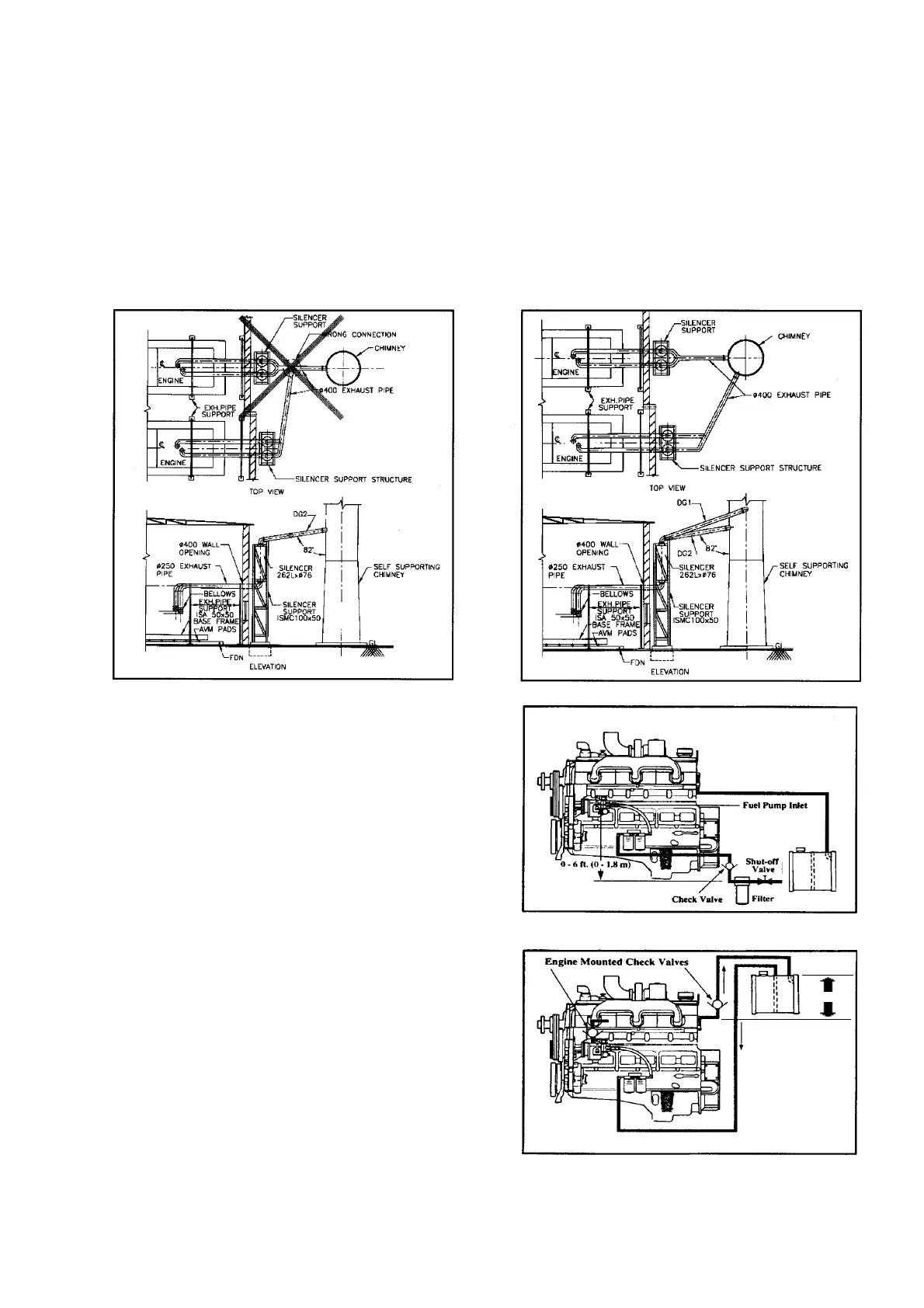

Common exhaust system for multiple engines

G.12 Common exhaust system for multiple sets is not recommended due to condensation, excessive suction pressure,

entry of exhaust gases in non working engine, increased back pressure and lack of fail safe system availability.

However exhaust of two banks of V-engines can be connected, after silencer. Ensure that area of common pipe

is greater than sum of the areas of individual pipes.

G.13 Exhaust of engines can be directly connected to chimney at different levels as shown.

RECOMMENDED (REF. G.13)NOT RECOMMENDED (REF. G.12)

H. Fuel System

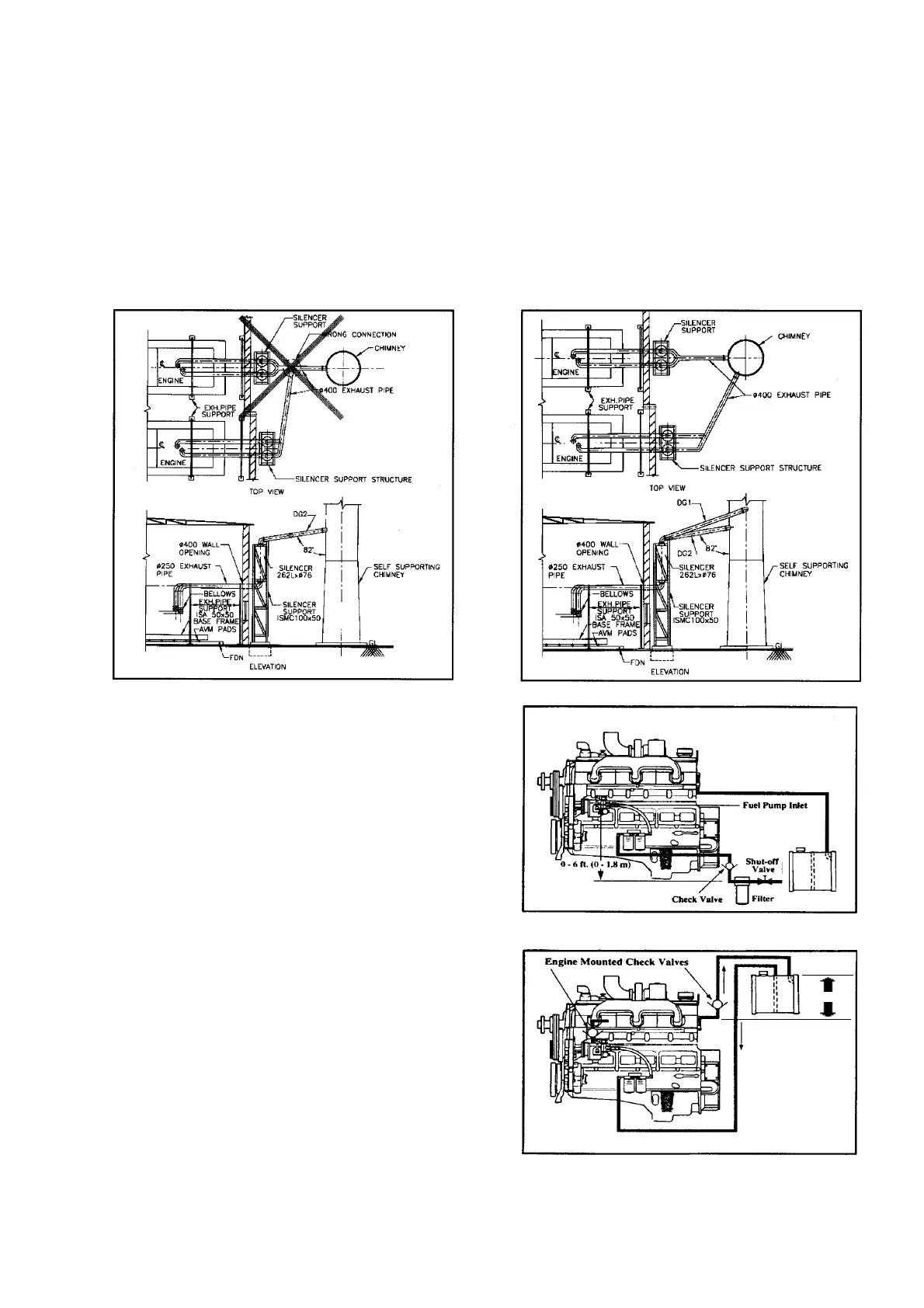

H.1 Fuel supply and return line restriction for PT fuel system

is max. 100 mm Hg.

Higher restriction leads to :

- Lower power

- Late stopping

- Engine die down

H.2 Typically fuel tank should be placed on the level as

that of engine i.e. floor mounted. Locate fuel tank such

that fuel outlet point (at bottom of fuel tank) is maximum

1.8 m (6 feet) below the fuel pump inlet or for top mounted

fuel tank, top side of fuel tank is max 1.5 m (5 feet)

above fuel return line. In case of Top Mounted tanks

non return valves are must in fuel supply and return

lines of specified value. Please contact OEMs /

Cummins for necessary details.

For AMF critical start engines, minimum 0.45 m (18”)

of gravity fuel feed needs to be provided to fuel pump

at inlet connection.

Ref. H.2

Ref. H.2

Loading...

Loading...