31

MAINTENANCEMAINTENANCE

1. The Gear Box is filled with oil at the factory and should not require periodic

flushing. If the Gear Box is opened for repair, flush by filling the unit with

an AGMA #7 oil. Next, run the unit with no load for 3 minutes. Then, drain

and refill the unit with 28 fluid ounces of an AGMA #7 oil such as the ones

listed below.

Amoco – Amoco Worm Gear Oil

Chevron – Cylinder Oil 460X

Exxon – CYLESSTIC TK460

Mobil – 600 W Cylinder Oil

Shell – Sun Gear Oil 7C

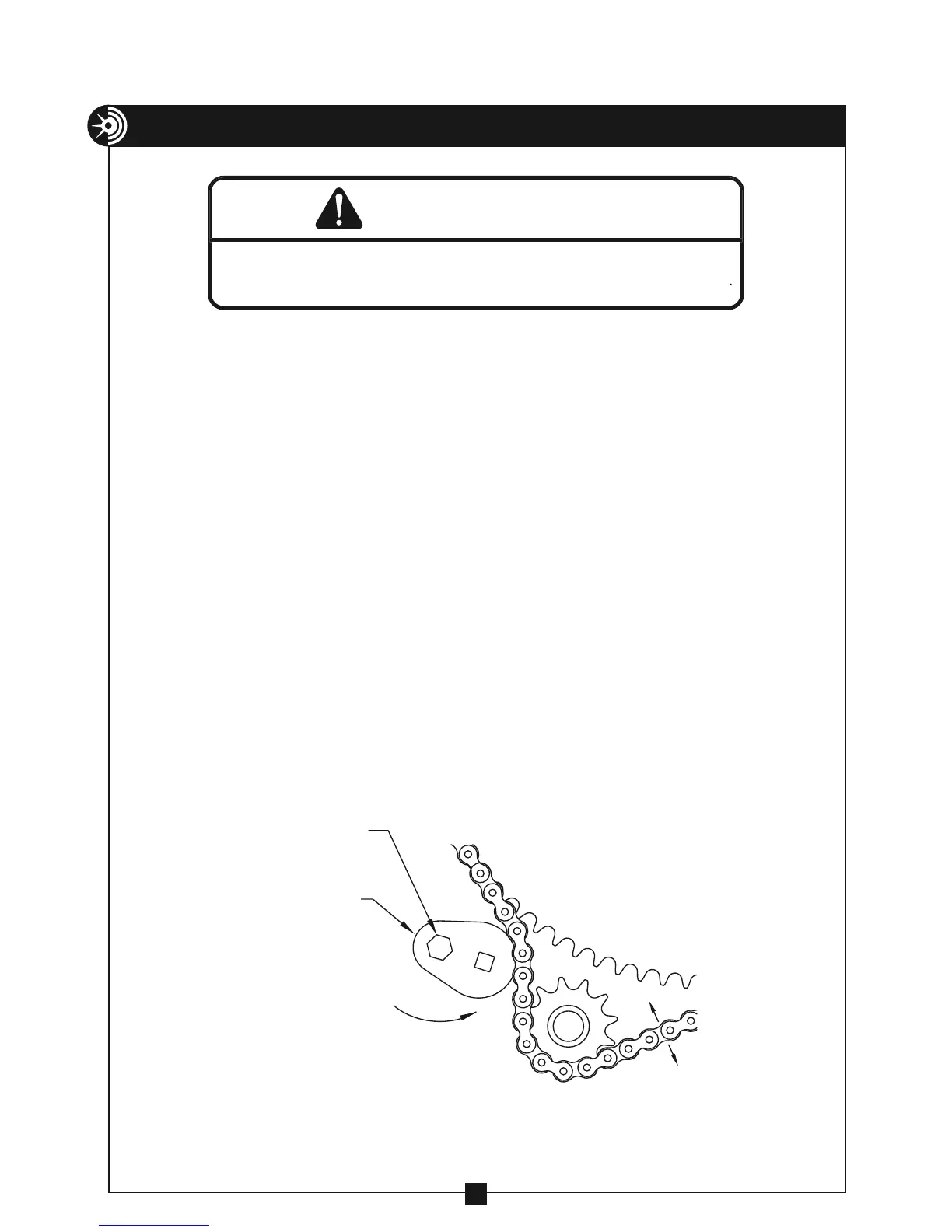

2. To inspect FRONT #60 chain tension:

• Remove face plate.

• To adjust, loosen hex screw with

3

⁄4" wrench and rotate chain tensioner

toward chain as shown until chain moves no more than a total of

1

⁄4".

See Figure 31 below.

• Grease chain periodically with a good quality MP grease.

guards or covers and

before servicing this bender. Failure to do so ma

TO LOCATE THE CENTER TO CENTER DISTANCE OF OFFSET

BENDING MARKS OTHER THAN THOSE LISTED IN CHART D, USE THE

FOLLOWING MULTIPLIERS: MULTIPLY THE HEIGHT OF THE OFFSET

DESIRED BY 3.86 ON 15° BENDS, 2 ON 30° BENDS, AND 1.4 ON 45° BENDS.

CONDUIT SIZE

1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

"X"

2-1/2

3-1/16

3-1/16

4

4-3/4

4-3/4

CHART D

OFFSET

HEIGHT

2"

4"

6"

8"

10"

12"

14"

16"

18"

20"

22"

30° 45°15°

MAX

CONDUIT

SIZE

CENTER

TO

CENTER

MAX

CONDUIT

SIZE

CENTER

TO

CENTER

MAX

CONDUIT

SIZE

CENTER

TO

CENTER

3/4"

1-1/2"

2"

3/4"

1-1/2"

2"

1"

1/2"

1-1/4"

1"

1-1/2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

7-3/4"

61-13/16"

15-7/16"

23-3/16"

30-7/8"

38-5/8"

46-3/8"

54-1/16"

69-9/16"

77-1/4"

85"

7-5/16"

11-15/16"

15-15/16"

19-15/16"

23-15/16"

27-15/16"

31-15/16"

35-15/16"

39-15/16"

43-15/16"

8-5/16"

11-1/16"

13-13/16"

16-5/8"

19-7/16"

22-1/4"

25-1/16"

27-15/16"

30-3/4"

FIGURES ARE APPROXIMATE

CHART E

END OF CONDUIT

TO START OF BEND

OFFSET

HEIGHT

ANGLE

ROTATE CHAIN

TENSIONER UPWARD

TO TIGHTEN CHAIN

CHAIN TENSIONER

HEX SCREW

1/4" MAX

LARGE

HOLES

SMALL HOLES

LARGE DRIVE STUD

LARGE DRIVE STUD

SMALL DRIVE STUD

SMALL DRIVE STUD

BENDING SHOE

Figure 31

Loading...

Loading...