FUEL

Use only the Ultra-low sulfur diesel.

(Inclued sulfur 15PPM).

Use a strainer when pouring

fuel into the tank. Otherwise,

foreign materials or sand may

enter the fuel system, causing

a problem to the high pressure

fuel injection pump and other

parts.

Do not leave the fuel tank

e mp ty. I f t h e f u el t an k i s

empty, air may enter the fuel

system. Bleeding is necessary

before the next engine start.

Be careful not to spill during

refueling. If fuel is spilled, it

should be wiped off immedi-

ately, or it may cause a re.

•

•

•

IMPORTANT

1. Check if the fuel level is below the

lower limit.

2. Use ultra-low sulfur diesel fuel only.

As other fuel is unknown of its qual-

ityorlowquality,useonlyspecied

fuel. Also, kerosene has low octane

number and can harm the engine.

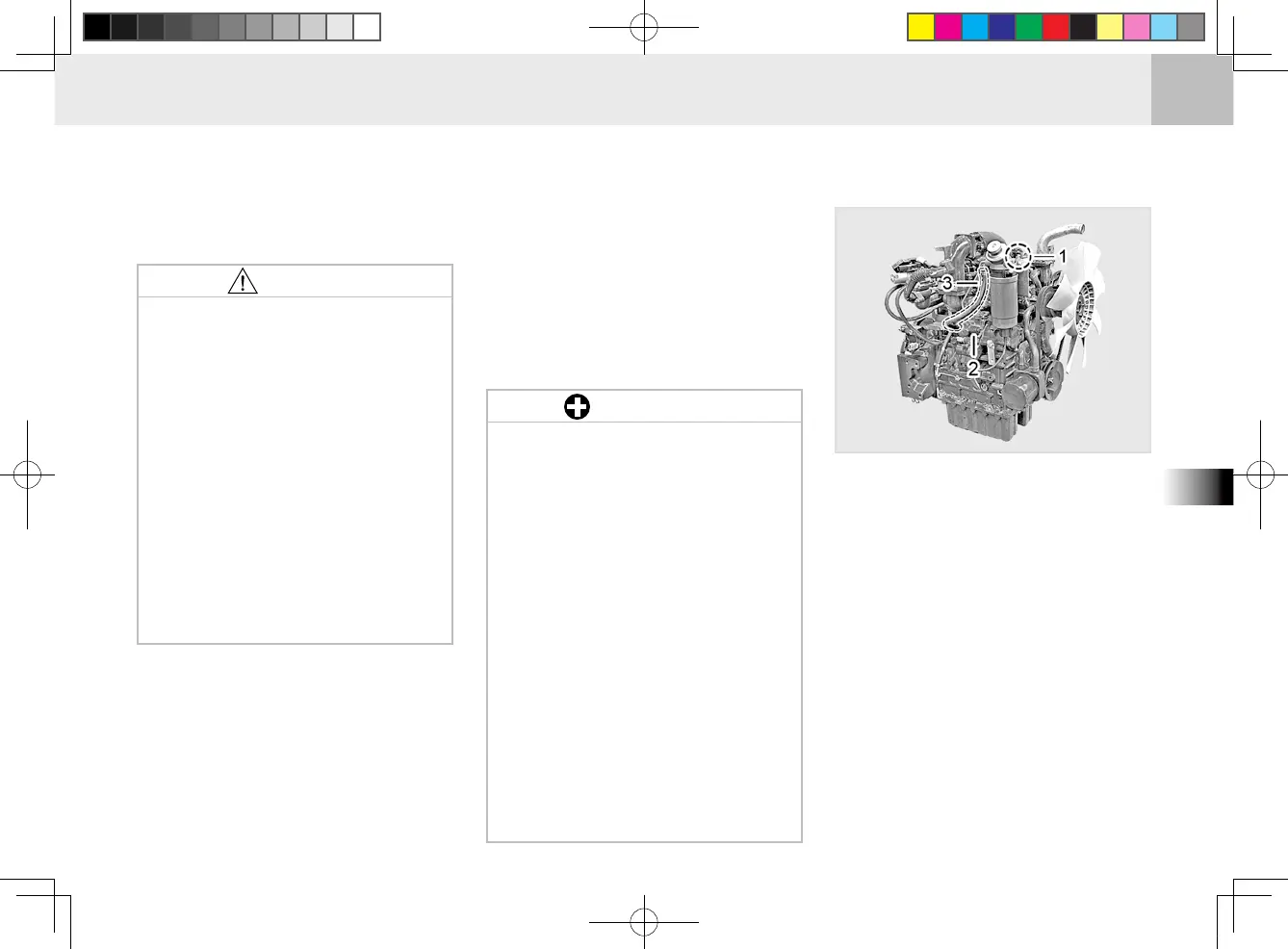

FUEL LEVEL INSPECTION AND FUELING

Check the fuel pipe every 200 hours.

1.

If any clamp is loose, apply a small

amount of oil to the band bolt and

tighten

itrmly.

2. Rubber fuel pipes can be worn natu-

rally regardless of operation time of

the engine. Therefore, replace them

every two years.

3. If any pipe or clamp is worn prema-

turely, replace it immediately.

CHECKING FUEL PIPE

(1) Bleeding bolt (2) High-pressure fuel pump

(3) Fuel Pipe

To avoid accidents:

Do not mix diesel fuel with

gasoline or alcohol. It can ex-

plode.

During refueling, make sure

to stop the engine in advance

and keep flammables away

from the engine.

If a different type of fuel, such

as gasoline, is added into the

fuel tank, it can damage the

high pressure pump. Never

replenish the tank with a dif-

ferent type of fuel.

•

•

•

CAUTION

TE4O501b

Loading...

Loading...