D1146/D1146TI/DE08TIS

MAINTENANCE MANUAL

74

Printed in Jan. 2001 PS-MMA0415-E1A

shaft, then assemble the oil seal using an oil seal fitting jig.

3.3.8. Flywheel

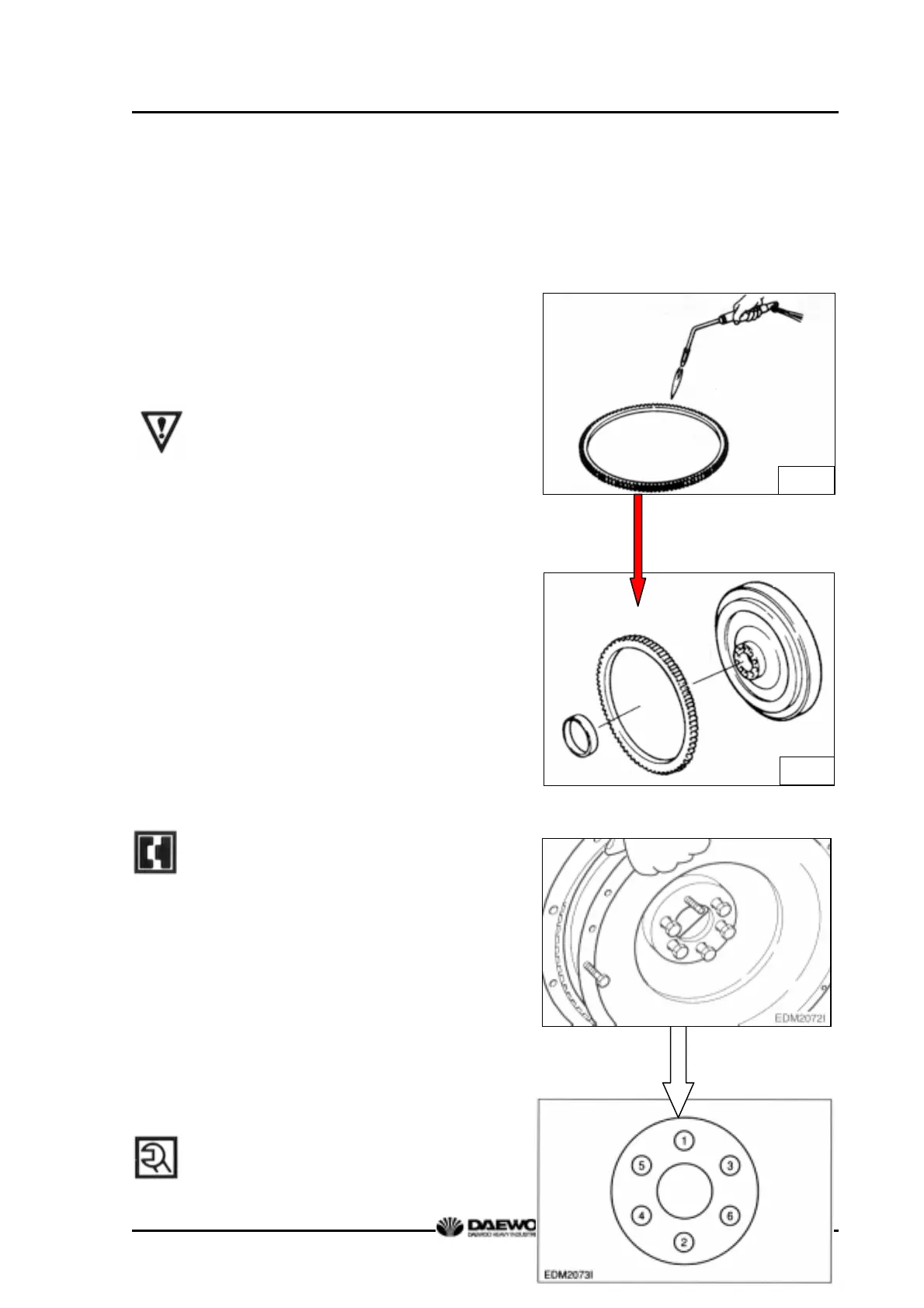

z Installation of flywheel ring gear

With a gas burner, heat the ring gear

evenly until heat expansion takes place,

then install it using a hammer.

CAUTION :

Do not allow the temperature of the ring

gear to exceed 200 °C (390 °F).

z By means of mandrel, assemble pilot

bearing to the flywheel.

z By means of mandrel, press in the wear

ring at the backward face.

z Install a guide bar into a bolt hole on

the crank shaft, and lift the flywheel to

align the dowel pin with the pin hole on

the flywheel for temporary assembly

operation.

z Coat the adhesive (#271 Loctite) over the

assembling bolts and install bolts in the

remaining holes. After that take out the

guide bar, then install a bolt in the hole

where the guide bar had been inserted.

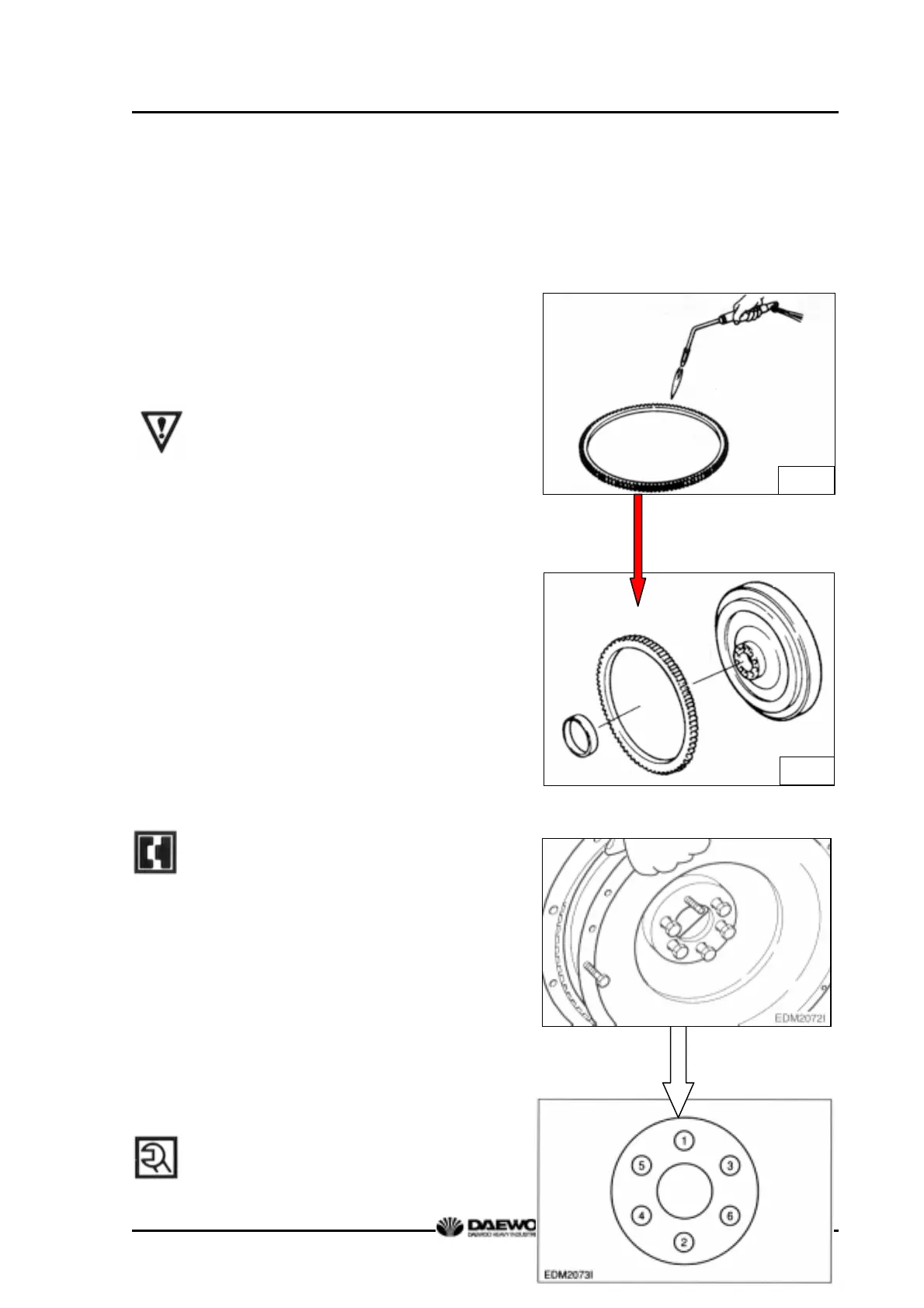

z According to the order of tightening

tighten the fixing bolts using a torque

wrench in a diagonal sequence to

wear ring

ring gear

G1031

M1122

Loading...

Loading...