CoolIng: MulTIsTage

Compressor Staging

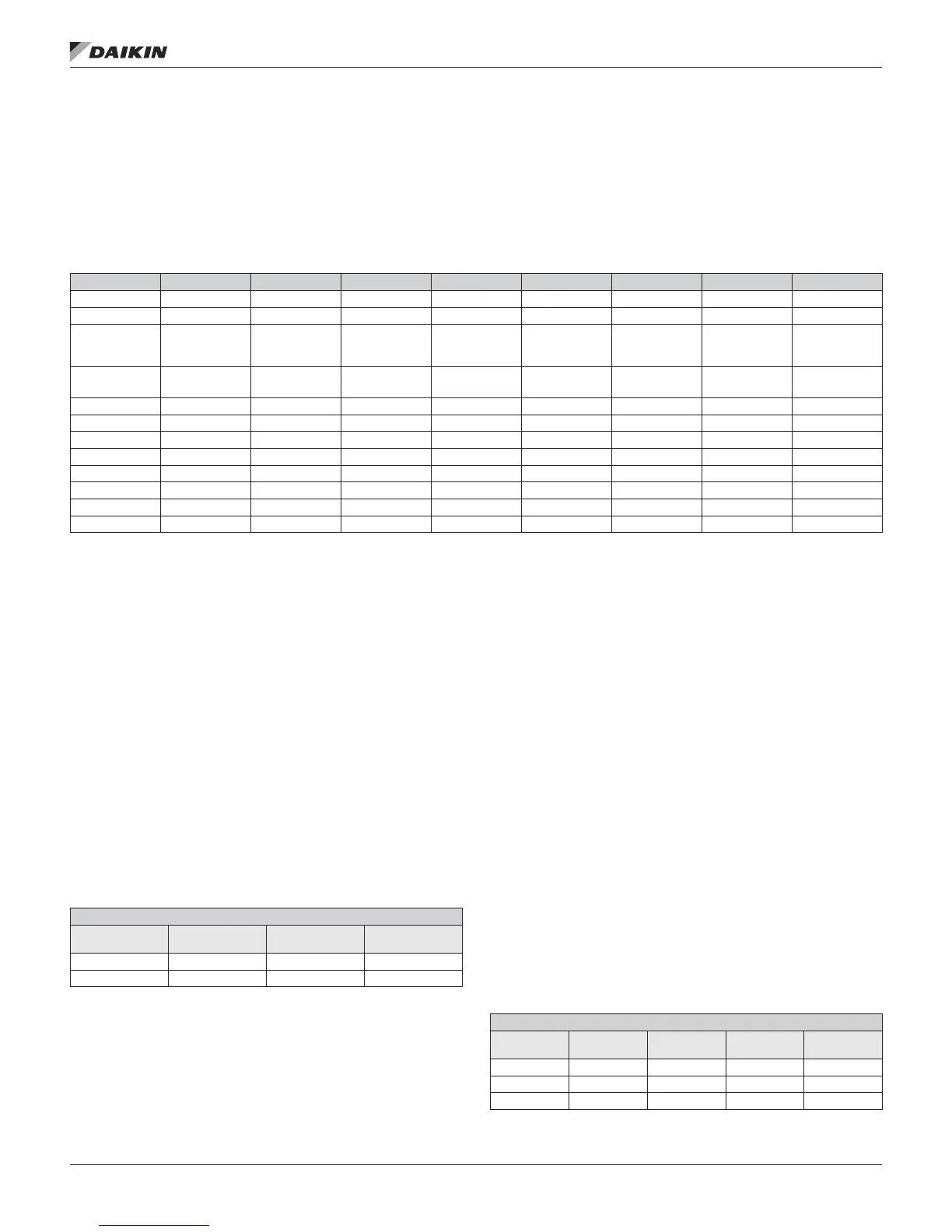

The following table is provided for reference indicating the

compressors that are included in each circuit for all the RTU

and SCU compressor congurations.RTU & SCU Compressor/

Circuit Congurations

Table 14: RTU & SCU Compressor/Circuit Congurations

Comp Cong Circuit #1 Circuit #2 Circuit #3 Circuit #4 Circuit #5 Circuit #6 Circuit #7 Circuit #8

2/2/2 1 2 NA NA NA NA NA NA

2/2/3 1 2 NA NA NA NA NA NA

3/2/4

(RTU R22/R407

& SCU)

1 & 3 2 NA NA NA NA NA NA

3/2/4

(RTU R410A)

1 2 & 4 NA NA NA NA NA NA

3/3/3 1 2 3 NA NA NA NA NA

4/2/4 1 & 3 2 & 4 NA NA NA NA NA NA

4/4/4 1 2 3 4 NA NA NA NA

6/2/6 1, 3 & 5 2, 4 & 6 NA NA NA NA NA NA

6/6/6 1 2 3 4 5 6 NA NA

6/3/6 1 & 3 2 & 4 5 & 6 NA NA NA NA NA

8/4/8 1 & 3 2 & 4 5 & 7 6 & 8 NA NA NA NA

8/8/8 1 2 3 4 5 6 7 8

RTU/SCU-Two Unequal Sized Compressors,

Two Circuits, Three Stages (2/2/3)

With this conguration there is only one xed sequence. If both

circuits are enabled the Maximum Cooling stages is set to 3. If

circuit 2 is disabled the maximum cooling stages is set to 1 and

compressor 1 is staged on and off to maintain the temperature

setpoint. If circuit 1 is disabled the maximum cooling stages is

set to 2 and compressor 2 is staged on and off to maintain the

temperature setpoint.

If a circuit is disabled and then becomes re-enabled, no

change occurs until a new stage up or down request occurs.

At this time the staging is re-aligned to the “normal” condition

for the new stage.

NOTE: During this re-alignment, the cooling stage time

guaranteed on and off times must be observed as

well as a minimum of 10 seconds between starting

more than one compressor.

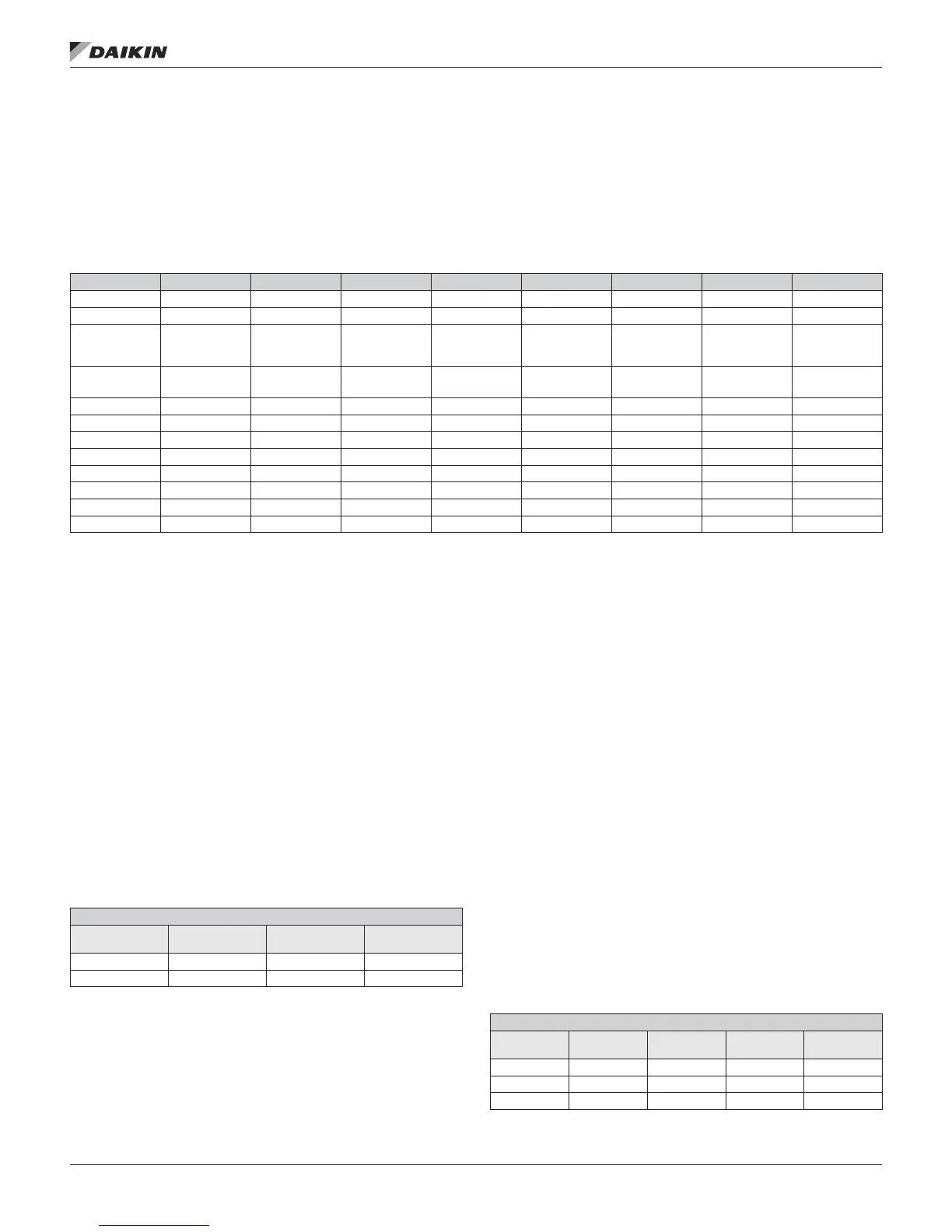

Table 15: RTU Standard Staging

Compressor Staging

Staging

Sequence

Stage 1

Compressor

Stage 2

Compressors

Stage 3

Compressors

Std-1 1 2 1, 2

StgdClgCap 33% 67% 100%

RPS/SCU-Two Small Comps on Circuit # 1, One

Large Comp on Circuit # 2, Four Stages (RTU

w/3/4/2 R22 or R407C or SCU)

With this conguration there are two xed sequences used

when both circuits are enabled.

If both circuits are enabled, the staging sequence is Std-

1 if compressor # 1 has fewer hours than compressor # 3

and the staging sequence is Std-2 if compressor # 1 does

not have fewer hours than compressor # 3. If Circuit #1 is

disabled compressor # 2 is staged on and off to maintain

the temperature setpoint. If Circuit #2 is disabled the staging

sequence is set to Std-1 if comp #1 has fewer hours than comp

#3 and the staging sequence is set to Std-2 if comp #1 does

not have fewer hours than comp #3. If a circuit is disabled

and then becomes re-enabled, no change occurs until a new

stage up or down request occurs. At this time the staging is

re-aligned to the “normal” condition for the new stage. When

both circuits are enabled the staging sequence is changed only

when the number of stages is zero or Maximum Cooling stages

NOTE: During this re-alignment, the cooling stage time

guaranteed on and off times must be observed as

well as a minimum of 10 seconds between starting

more than one compressor.

Table 16: RPS/SCU Standard Staging

Compressor Staging

Staging

Sequence

Stage 1

Compressor

Stage 2

Compressors

Stage 3

Compressors

Stage 4

Compressors

Std-1 1 1, 3 2, 3 1, 2, 3

Std-2 3 3, 1 1, 2 1, 2, 3

StgdClgCap 25% 50% 75% 100%

CoolIng: MulTIsTage

www.DaikinApplied.com 31 IM 919-3 • MICROTECH III CONTROLLER

Loading...

Loading...