Staged Cooling Outputs

Rooftop air handlers can be ordered with factory-installed

evaporator coils and the capability to control up to eight stages

of eld-supplied cooling equipment. The MicroTech III outputs

designated for these applications are DO 1-4 and DO 7,8 on

the MCB and DO 1,2 on Expansion board A. These outputs

are wired to terminal block TB4 in the main control panel for

connection to the eld supplied condensing unit. Refer to the

as-built wiring schematics for the unit

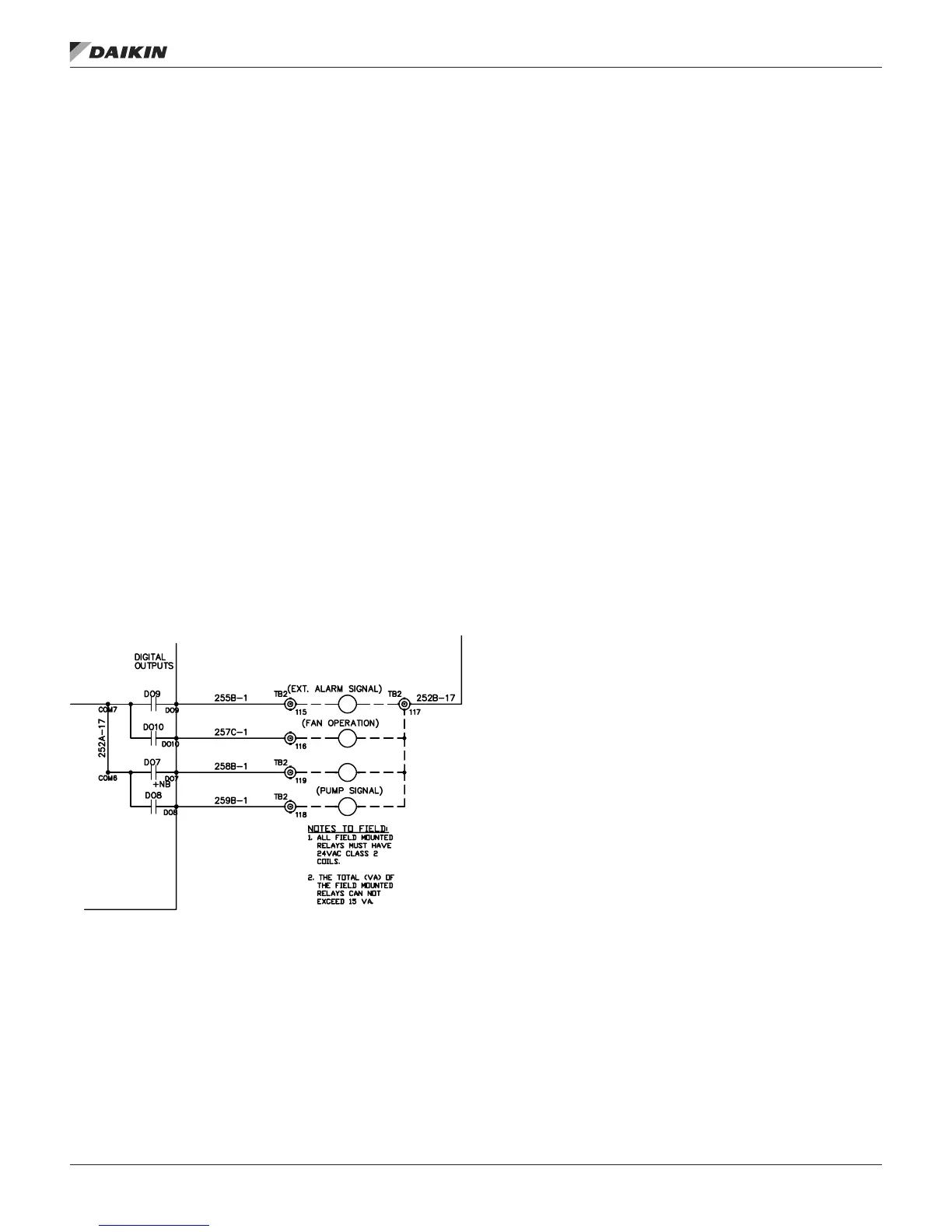

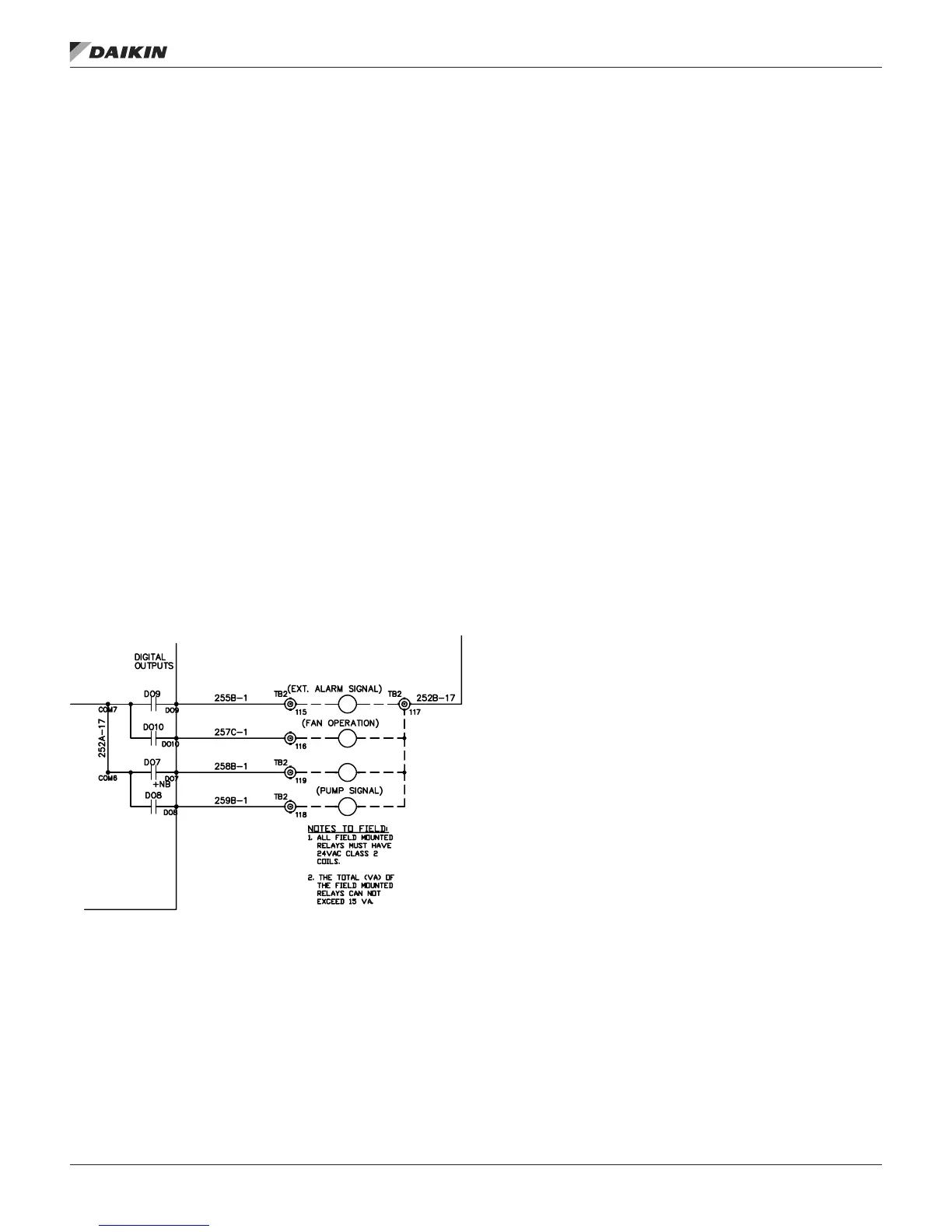

Outdoor Damper

When applicable the Outdoor Damper Output supplies 24

VAC to terminal 119 on the eld terminal block (TB2) when the

output is on. To use this signal, wire the coil of a eld supplied

and installed 24 VAC pilot relay across terminals 119 and 117

on TB2. When this output is on, 24 VAC is supplied from the

T3 control transformer through the output relay to energize the

eld relay. Refer to the as-built wiring diagrams.

Pump Signal

When applicable the Pump Signal Output supplies 24 VAC to

terminal 113 on the eld terminal block (TB2) when the output

is on. To use this signal, wire the coil of a eld supplied and

installed 24 VAC pilot relay across terminals 113 and 117 on

TB2. When this output is on, 24 VAC is supplied from the T3

control transformer through the output relay to energize the

eld relay. Refer to the as-built wiring diagrams.

Figure 18: Fan Operation Output Wiring Diagram

Field Analog Input Signals

The following inputs may be available for eld connections to a

suitable device.

NOTE: The eld needs to be careful not to ground their

transformer for a eld signal to chassis ground. They

need to use the same ground as the controller to

prevent a voltage potential above 3V. This voltage

potential can damage the Microtech III Controller.

Zone Temperature Sensor Packages

A zone temperature sensor (ZNT1) is optional for all units

except for the 100% outdoor air

Zone Control unit in which case one is required. In all unit

congurations, however, a zone temperature sensor is required

to take advantage of any of the following standard controller

features:

• Unoccupied heating or cooling

• Pre-occupancy purge

• Discharge air reset based on space temperature (DAC

units only)

• Remote timed tenant override

• Remote set point adjustment (CAV-ZTC units only)

A Zone Setpoint Source (Apply Tstat change =No/Yes)

parameter is provided on the keypad/display to allow for

setting the setpoint via the zone thermostat input. The menu is

located in the Heating/Cooling Changeover Setup menu of the

Commission Unit section. When Apply Tstat change is set to

No, the Occupied Cooling Setpoint and the Occupied Heating

Setpoint may be set through the keypad or via a network signal

(all units). In this case these setpoints are changed whenever

the network or keypad value changes.

When Apply Tstat change is set to Yes these setpoints can

only be adjusted through the zone thermostat. This option is

available for all control types (Zone, DAT, and Single zone

VAV). Heating and cooling setpoints must not overlap. The

Occupied Heating Setpoint must be equal to or less than the

Occupied Cooling Setpoint. If a conict occurs from values

entered via the keypad or network, Occupied Heating Setpoint

is automatically adjusted down to eliminate the conict.

When Apply Tstat change =No, the Occupied Heating and

Cooling setpoints may be changed manually by changing the

setpoint displayed on the keypad.

When Apply Tstat change =Yes, the Occupied Cooling Setpoint

is set through a setpoint adjustment included with a wall

mounted space sensor. When the Occupied Cooling Setpoint is

changed by more than 0.5 degrees through the wall mounted

sensor, the Occupied Heating Setpoint is raised or lowered the

same amount so that the difference between the Cooling and

Heating setpoints does not change.

The dead band between the Occupied Cooling Setpoint and

the Occupied Heating Setpoints can be set by setting the Apply

Tstat change to No, setting the differential via the keypad and

resetting the Apply Tstat change back to Yes. The setpoint

adjustment is a resistance value that varies from 5000 ohm to

15000 ohms.

fIeld wIrIng

www.DaikinApplied.com 25 IM 919-3 • MICROTECH III CONTROLLER

Loading...

Loading...