18 | Piping installation

Installer and user reference guide

81

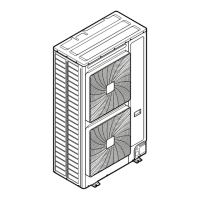

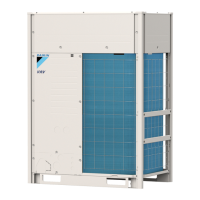

RXYSA4~6A7V/Y1B

VRV 5-S system air conditioner

4P600330-1D – 2023.02

18 Piping installation

In this chapter

18.1 Preparing refrigerant piping ................................................................................................................................................... 81

18.1.1 Refrigerant piping requirements ........................................................................................................................... 81

18.1.2 Refrigerant piping material .................................................................................................................................... 81

18.1.3 To select the piping size ......................................................................................................................................... 82

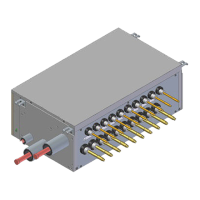

18.1.4 To select refrigerant branch kits ............................................................................................................................ 83

18.1.5 Refrigerant piping length and height difference ................................................................................................... 84

18.2 Connecting the refrigerant piping.......................................................................................................................................... 85

18.2.1 About connecting the refrigerant piping ............................................................................................................... 85

18.2.2 Precautions when connecting the refrigerant piping............................................................................................ 85

18.2.3 Pipe bending guidelines ......................................................................................................................................... 86

18.2.4 To remove the spun pipes ..................................................................................................................................... 86

18.2.5 To braze the pipe end ............................................................................................................................................ 87

18.2.6 Using the stop valve and service port.................................................................................................................... 88

18.2.7 To connect the refrigerant piping to the outdoor unit ......................................................................................... 89

18.2.8 To connect the refrigerant branching kit .............................................................................................................. 91

18.3 Checking the refrigerant piping.............................................................................................................................................. 92

18.3.1 About checking the refrigerant piping................................................................................................................... 92

18.3.2 Checking refrigerant piping: General guidelines ................................................................................................... 93

18.3.3 Checking refrigerant piping: Setup ........................................................................................................................ 93

18.3.4 To perform a leak test ............................................................................................................................................ 94

18.3.5 To perform vacuum drying .................................................................................................................................... 95

18.1 Preparing refrigerant piping

18.1.1 Refrigerant piping requirements

NOTICE

The piping and other pressure-containing parts shall be suitable for refrigerant. Use

phosphoric acid deoxidised seamless copper for refrigerant piping.

INFORMATION

Also read the precautions and requirements in the "2 General safety

precautions"[48].

▪ Foreign materials inside pipes (including oils for fabrication) must be

≤30mg/10m.

18.1.2 Refrigerant piping material

▪ Piping material: phosphoric acid deoxidised seamless copper

▪ Flare connections: Only use annealed material.

▪ Piping temper grade and thickness:

Outer diameter (Ø) Temper grade Thickness (t)

(a)

6.4mm (1/4")

9.5mm (3/8")

12.7mm (1/2")

Annealed (O) ≥0.80mm

15.9mm (5/8") Annealed (O) ≥0.99mm

19.1mm (3/4") Half hard (1/2H) ≥0.80mm

Loading...

Loading...