Page 25 of 58

SK2019 FMCD-V-ECM-001

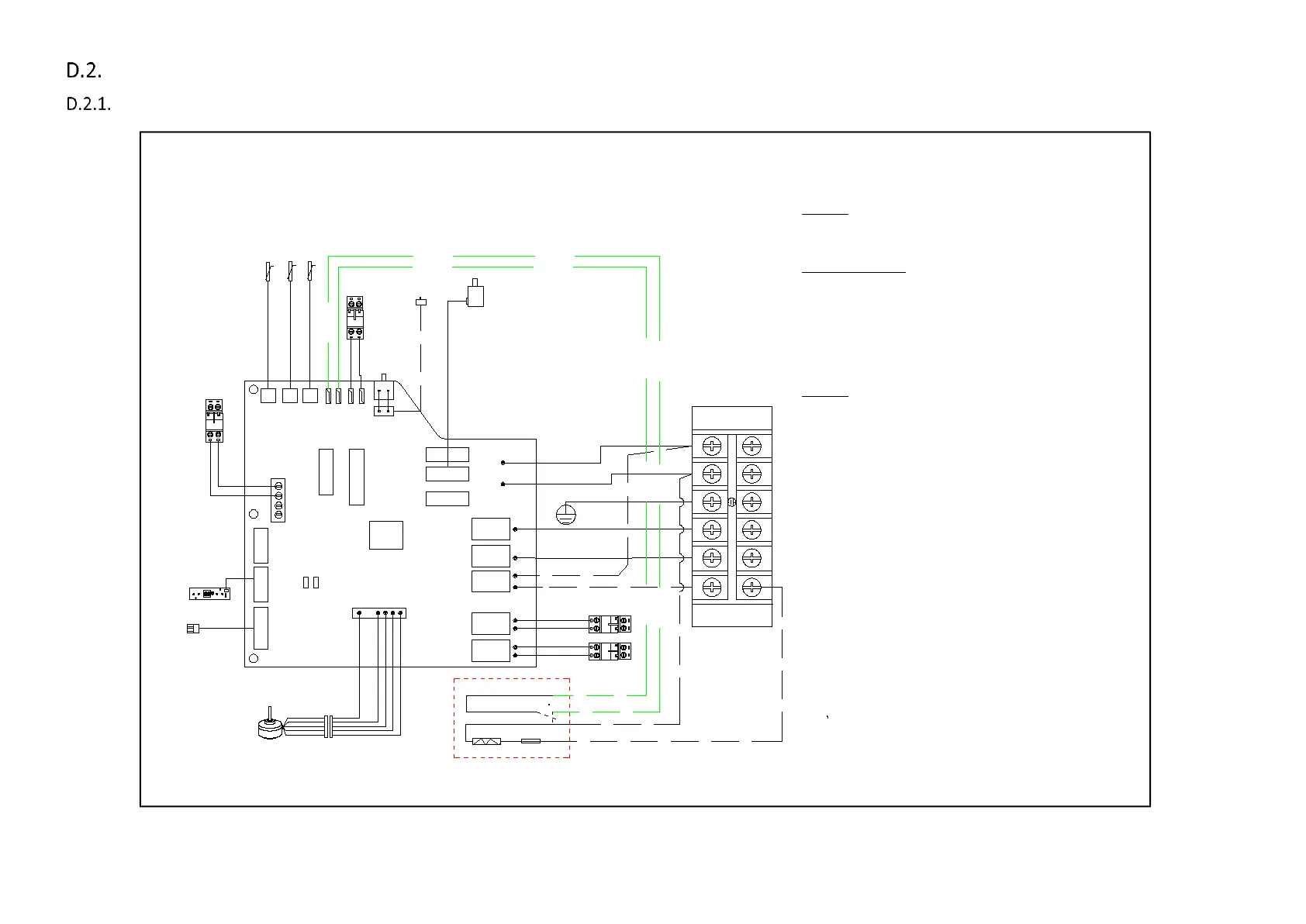

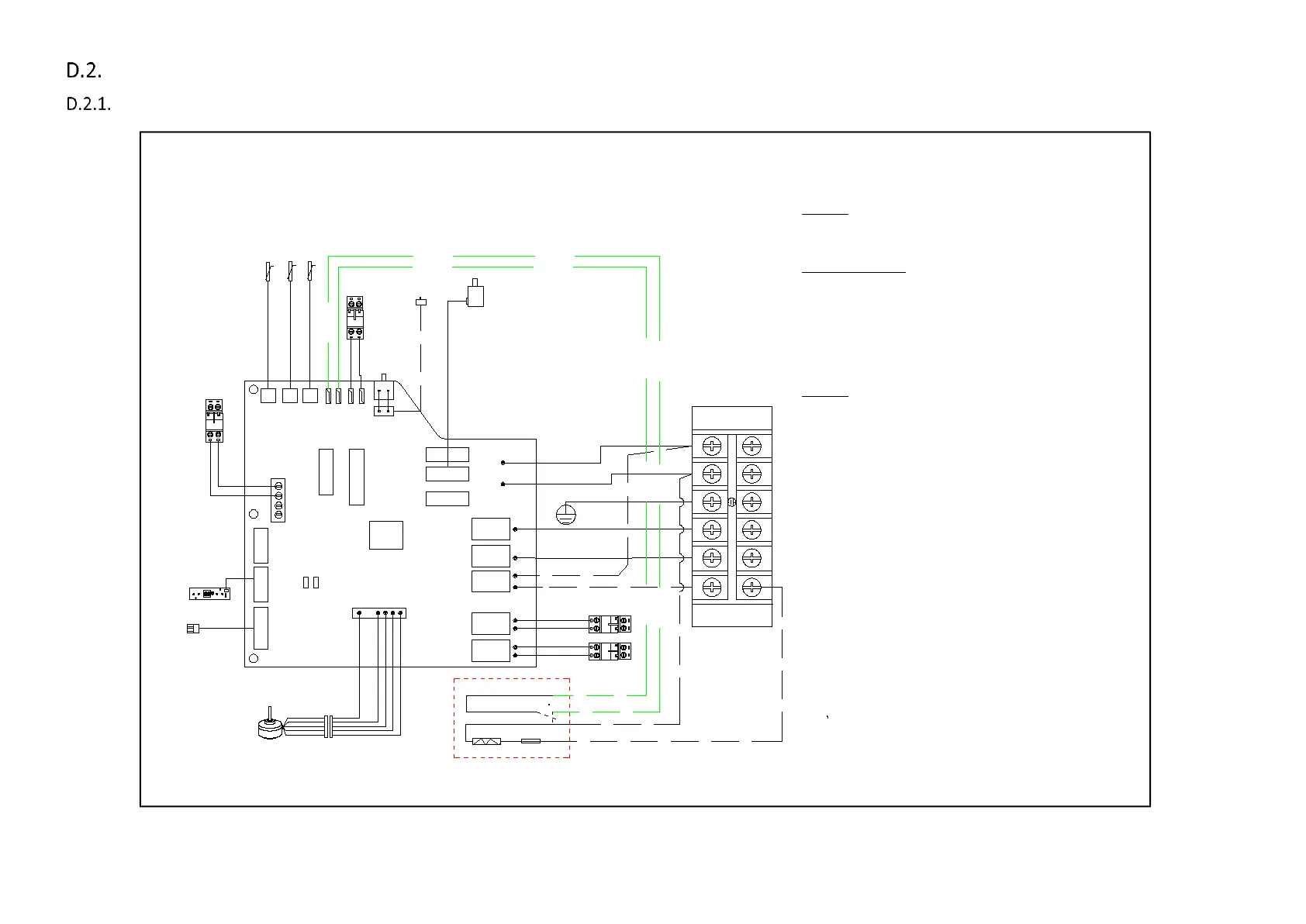

Wiring Diagrams

2-pipe system Total Type Control

Reset switch for SWC-20, 24, 30

Louver Stepping motor

CN1

Dip switch A

N

L

KEY

N

L

V1 V2

VALVE1

HEAT

VALVE2

AUX1

AUX2

FUSE

Dip switch B

Wired Wall

pad plug

A B A B

Yellow/Green

Reset switch SWC06~18

CN4

Plug

Legend:

DIPA-S1

SW1-5: set the unit address

SW6: set unit type: master or slave

Mode Configuration

SW7=0;SW8=0; unit operates in cooling/heating;

SW7=0;SW8=1; unit operates in cooling/heating

with booster EH;

SW7=1;SW8=0 ; unit operates in cooling

SW7=1;SW8=1; unit operates in cooling

with primary EH

DIPB-S2

SW1:Occupancy connect setting

SW2: Unit configuration setting: 0=2pipe system;

1=4-pipe system;

SW3: on/off valve configuration:0= no valve

1=with valve

SW4:preheat setting: 0=36C; 1=28C

SW5,SW6,S3(jump)----RPM selection.

L\N----Power supply

VALVE1:230V on/off valve output;

VALVE2:230V on/off valve output;

HEAT----Electrical heater

AI1:Return air temperature sensor(Tr) ;

AI2:Indoor coil temperature sensor1 (Ti1) ;

AI3:Indoor coil temoeraturesensor 2 (Ti2) ;

AUX1:Voltage free contact; ON:unit in heating mode.

AUX2:Voltage free contact; ON:unit in cooling mode.

ON/OFF:Occupancy contact

CN1 2---Stepping motor

CN3---Serial BUS contacts.

CN4---Ec motor

DIS---Led receiver display

TTL---wired wall pad

CPU

S4 S3

AI3 AI2 AI1

CN2

prog

EH

DIS

TTL1

S1

S2

CN3

ON/OFF

TERMINAL

{

chilled /hot water

4-pipe coil circut sensor

2 pipe sensor (Ti1)

Renturn sensor (Tr)

(Ti2):hot water

EC-S Unit wiring scheme

EH

B A

RS485 plug

A1 A1 A2 A2

Auxiliary heating contact

Auxiliary cooling contact

Electrical heater

FUSE

EC moter

DISPLAY

PROs

PRO contact

110C

IPA19-DL-EC-S

Loading...

Loading...