98 Capacity controller RS8ER302 © Danfoss 2016-02 AK-CH 650

Main switch

The main switch is used to stop and start the controlling function.

The switch-over has 2 positions:

- Normal controlling state (Setting = ON)

- Control stopped. (Setting = OFF)

In addition, one can also choose to use a digital input as an

external main switch.

If the switch-over or the external main switch is set at OFF, all the

control’s functions are inactive and an alarm is generated to draw

attention to this – all other alarms cease.

Refrigerant

Before regulation can be commenced, the refrigerant must be

dened.

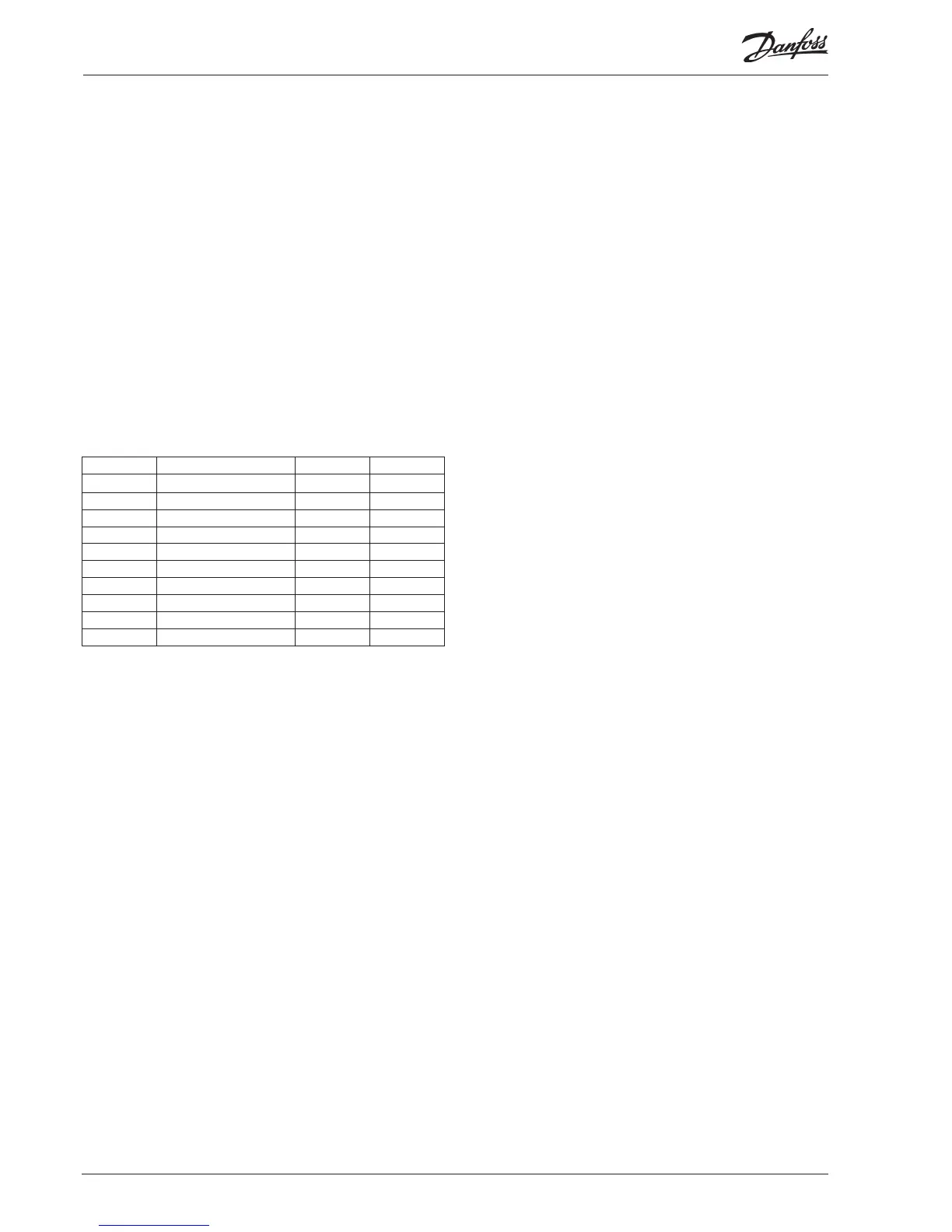

You can select one of the following refrigerants:

1 R12 12 R142b 23 R410A 34 R427A

2 R22

13

User dened

24 R170 35 R438A

3 R134a 14 R32 25 R290 36 R513A

4 R502 15 R227 26 R600 37 R407F

5 R717 16 R401A 27 R600a 38 R1234ze

6 R13 17 R507 28 R744 39 R1234yf

7 R13b1 18 R402A 29 R1270 40 R448A

8 R23 19 R404A 30 R417A 41 R449A

9 R500 20 R407C 31 R422A 42 R452A

10 R503 21 R407A 32 R413A

11 R114 22 R407B 33 R422D

The refrigerant can only be changed if the “Main switch” is set at

“stopped control”.

Warning: Incorrect selection of refrigerant can cause damage to

the compressor.

Sensor failure

If lack of signal from one of the connected temperature sensors or

pressure transmitters is registered an alarm will be given.

• When there is a S4 and P0 error regulation will continue with 50%

cut-in capacity during day operation and 25% cut-in capacity

during night operation – but minimum one step. (The values

can be set). The relay for "Extra cooling" will be activated in the

event of an error in the control sensor.

• In the case of an S4 error, control continues by suction pressure

P0. This is now with a reference that is 5K under the current

reference for S4.

• When there is a Pc error 100% condenser capacity will be cut in,

but the compressor regulation will remain normal.

• When there is an error on the Sd sensor the safety monitoring of

the discharge gas temperature will be discontinued.

• When there is an error on the Ss sensor the monitoring of the

superheat on the suction line will be discontinued.

• When there is an error on the outdoor temperature sensor

Sc3 the “FDD” function will cease. Regulation with variable

condensing pressure reference cannot either be carried out.

Instead you use the PC ref. min. value as reference.

• S7 error: See page 93.

NB: An incorrect sensor must be in order for 10 minutes before the

sensor alarm deactivates.

Sensor calibration:

The input signal from all connected sensors can be corrected. A

correction will only be necessary if the sensor cable is long and

has a small cross-sectional area. All displays and functions will

reect the corrected value.

Clock function

The controller contains a clock function.

The clock function is used only to change between day/night.

The year, month, date, hour and minutes must be set.

Note: If the controller is not equipped with a RTC module

(AK-OB 101A) the clock must be reset after each mains voltage

outage.

If the controller is connected to an installation with an AKA-

gateway or an AK system manager, this will automatically reset

the clock function.

Alarms and messages

In connection with the controller’s functions, there are a number

of alarms and messages that become visible in cases of fault or

erroneous operation.

Alarm history:

The controller contains an alarm history (log) that contains all

active alarms as well as the last 40 historical alarms. In the alarm

history you can see when the alarm began and when it stopped.

In addition, one can see the priority of each alarm as well as when

the alarm has been acknowledged and by which user.

Alarm priority:

Dierentiation is made between important and not-so-important

information. The importance – or priority – is set for some alarms

whilst others can be changed voluntarily (this change can only

be done with attachment of AK-ST service tool software to the

system and settings must be made in each individual controller).

The setting decides which sorting / action must be carried out

when an alarm is sounded.

• “High” is the most important

• “Log only” is the lowest

• “Interrupted” results in no action

Alarm relay

One can also choose whether one requires an alarm output on

the controller as a local alarm indication. For this alarm relay it is

possible to dene on which alarm priority it must react to – one

can choose between the following:

• “Non” – no alarm relay is used

• “High’ – Alarm relay is activated only with alarms with high

priority

• “Low - High’ – Alarm relay is activated only with alarms with “low”

priority, “medium” or “high” priority.

Miscellaneous

Loading...

Loading...