42 Capacity controller RS8ER302 © Danfoss 2016-02 AK-CH 650

Wiring

Decide during planning which function is to be connected and

where this will be.

1. Connect input and outputs

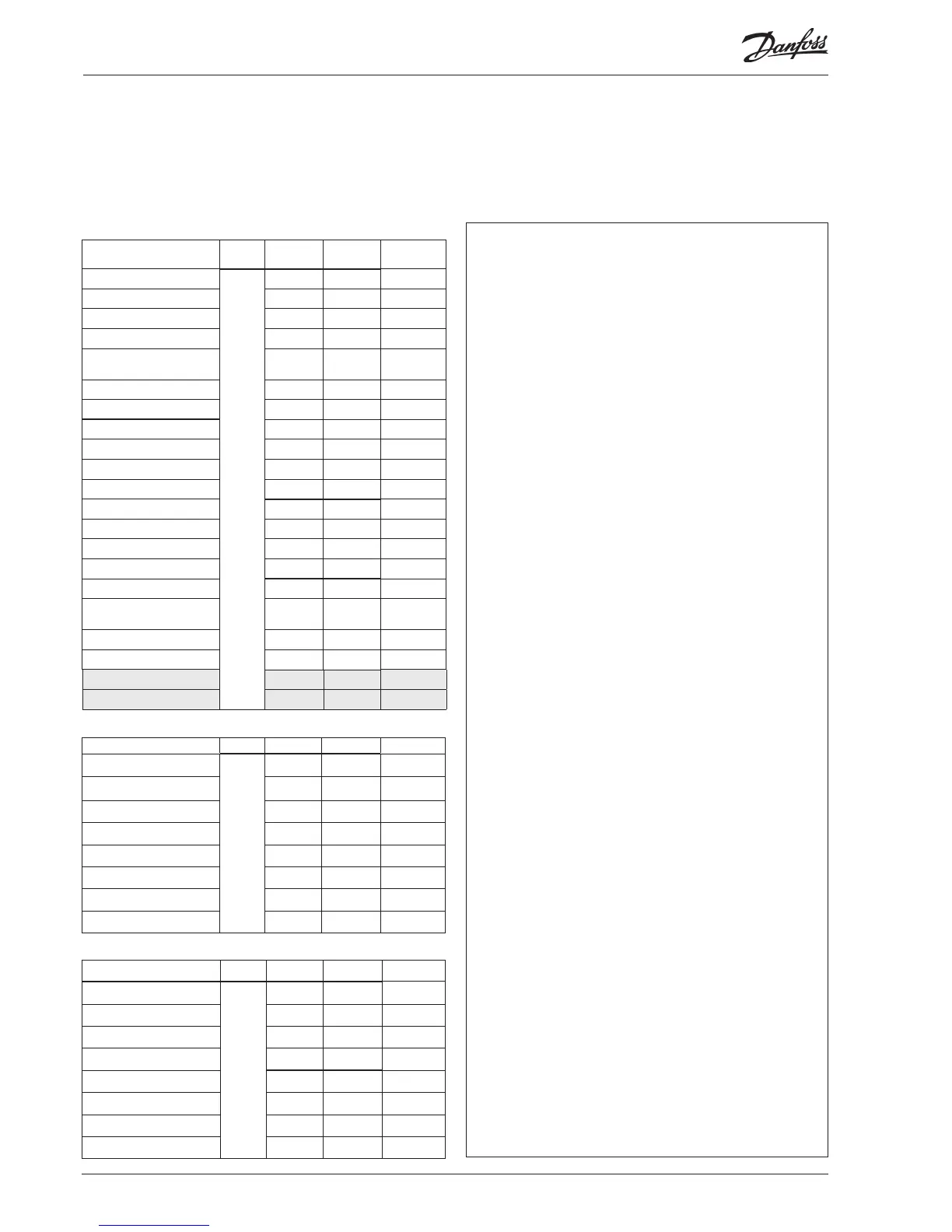

Here are the tables for the example:

Mounting and wiring - continued

The function of the switch functions can be seen in the last column.

There are AKS 32 pressure transmitters for several pressure ranges.

Here there are two dierent ones. One up to 12 bar and one up to 34 bar.

Signal Module Point

Terminal

Signal type /

Active at

Brine return temperature S3

1

1 (AI 1) 1 - 2

Pt 1000

Brine supply temperature S4

2 (AI 2) 3 - 4

Pt 1000

Consumption limitation

3 (AI 3) 5 - 6

Closed

Pump ow switch

4 (AI 4) 7 - 8

Open

Thermostat sensor in plant

room - Saux1

5 (AI 5) 9 - 10

Pt 1000

External main switch

6 (AI 6) 11 - 12

Closed

Outdoor temperature - Sc3

7 (AI 7) 13 - 14

Pt 1000

Discharge gas temperature - Sd

8 (AI 8) 19 - 20

Pt 1000

Suction gas temperature - Ss

9 (AI 9) 21 - 22

Pt 1000

Suction pressure - P0

10 (AI 10) 23 - 24

AKS32-12

Condenser pressure - Pc

11 (AI 11) 25 - 26

AKS32-34

Compressor 1 / VSD

12 (DO 1) 31 - 32

ON

Compressor 2

13 (DO 2) 33 - 34

ON

Compressor 3

14 (DO 3) 35 - 36

ON

Compressor 4

15 (DO 4) 37 - 38

ON

16 (DO 5) 39-40-41

Liquid injec. in heat ex-

changer

17 (DO6) 42-43-44

ON

Pump 1

18 (DO7) 45-46-47

ON

Pump 2

19 (DO8) 48-49-50

ON

Speed control of compressors

24 -

0-10 V

25 -

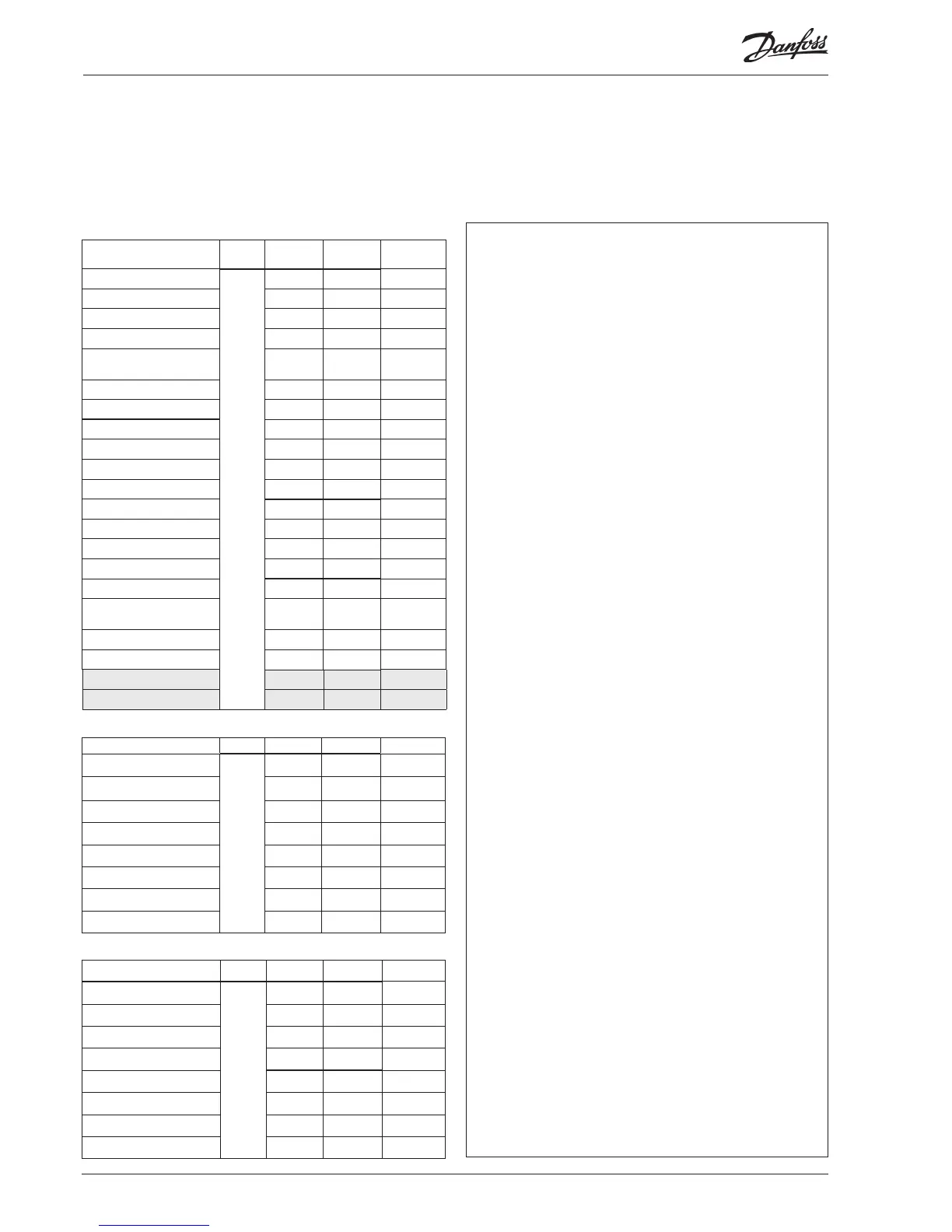

Signal Module Point Terminal Active at

Fan 1

2

1 (DO 1) 25-26-27

On

Fan 2

2 (DO 2) 28-29-30

On

Fan 3

3 (DO 3) 31-32-33

On

Fan 4

4 (DO 4) 34-35-36

On

Defrost

5 (DO 5) 37-38-39

On

Fan in plant room

6 (DO 6) 40-41-42

On

Alarm

7 (DO 7) 43-44-45

O

8 (DO 8) 46-47-48

Signal Module Point Terminal Active at

Compressor 1 Gen. safety

3

1 (DI 1) 1 - 2 Open

Compressor 2 Gen. safety 2 (DI 2) 3 - 4 Open

Compressor 3 Gen. safety 3 (DI 3) 5 - 6 Open

Compressor 4 Gen. safety 4 (DI 4) 7 - 8 Open

VSD, compressor speed 5 (DI 5) 9 - 10 Open

Frost protection 6 (DI 6) 11 - 12 Open

DI alarm, Receiver level 7 (DI 7) 13 - 14 Open

8 (DI 8) 15 - 16

Loading...

Loading...