D

GB

F

E

PT

I

TR

Ru

10 | AQ453249013813en-000201

© Danfoss | Climate Solutions | 2023.07

4| Compressor assembly

Duringoperation withcapacity regulator (Accessories,Chap.7), thechanging load can cause

increased running noises and belt drive vibrations.

4.3 V-belt drive

4.4 Main bearing load

4.5 Electromagnetic clutch assembly

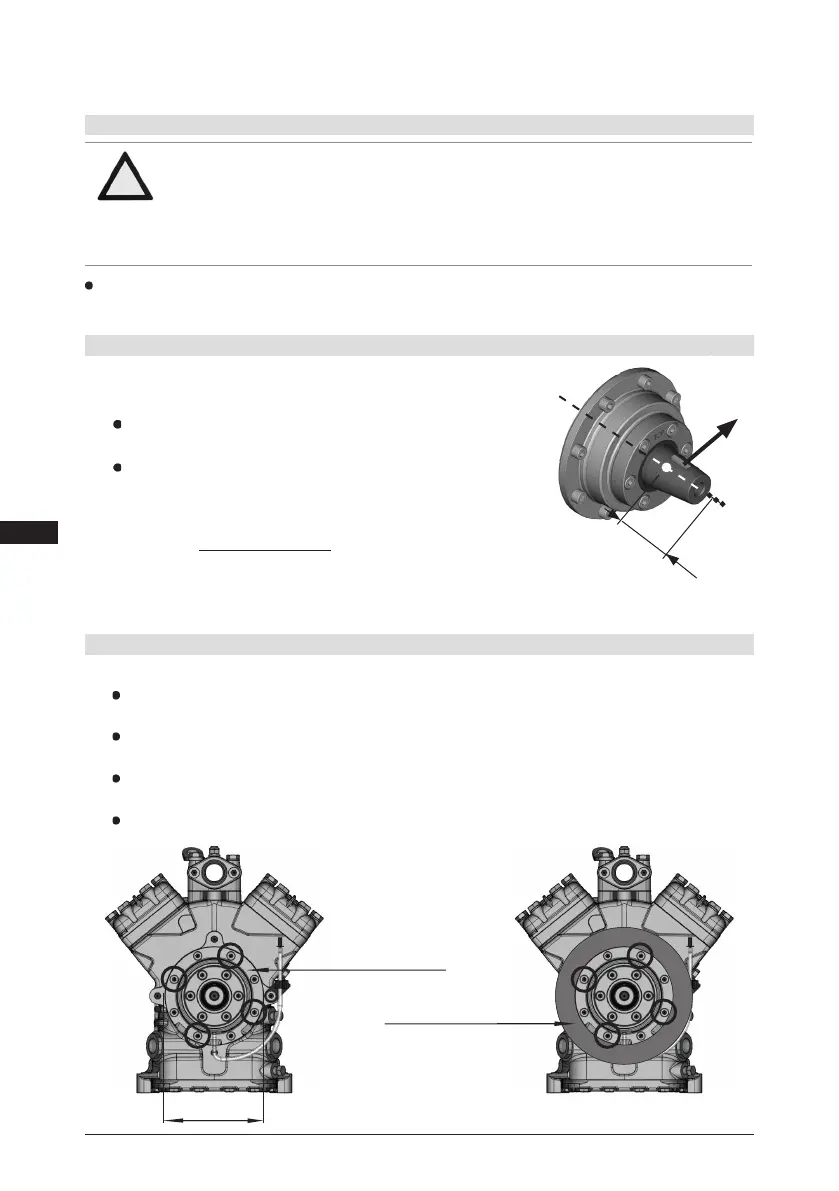

The following description applies for an electromagnetic clutch secured to a shaft.

Toabsorbthemagneticeldoftheelectromagneticclutch,thefrontbearingangehasa

snugtØ148h8(seeFig.8).

Toconnectthemagneticeld,loosenthe4cheeseheadscrewsM8onthebearingange

(seeFig.8).

Slidethemagneticeldtoasnugtandre-attachusingthefourcheeseheadscrewsM8

(Fig.9).Screwtorque=37Nm.

Further assembly of the electromagnetic clutch according to the clutch manufacturer.

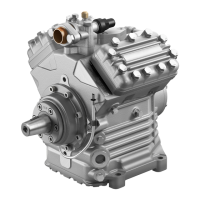

To prevent the belt drive overloading the compressor main bearing,

ensure that:

The force applied at the force engagement force by the belt

tension(seeFig.7)mustnotexceedF

max

= 2750 N.

If the force engagement point shifts forwards (see Fig.11, small

point),theforceF

max

reduces as per the following formula:

F

max

=

245 kNmm

(90mm+L

1

[mm])

F

max

= 2750 N

M

bmax

= 245kNmm

L

1

(mm)

Fig. 7

ATTENTION Inappropriately designed belt drives, especially belt knocking

(offsets, inclinations) or excessive tensioning forces can cause

compressor damage! Make sure that the drive belt is designed

correctly,e.g.byusingtensionersandselectingthebeltproleand

the belt length.

Fig. 8

Bearingange,front

Magneticeld

Fig. 9

148 h8

Loading...

Loading...