D

GB

F

E

PT

I

TR

Ru

© Danfoss | Climate Solutions | 2023.07

AQ453249013813en-000201| 15

5| Commissioning

Make sure that the suction and discharge line valves are open.

Withthecompressorswitchedoff,addtheliquidrefrigerantdirectlytothecondenserorreceiver,

breaking the vacuum.

If the refrigerant needs topping up after starting the compressor, it can be topped up in vapour

formonthesuctionside,or,takingsuitableprecautions,alsoinliquidformattheinlettothe

evaporator.

After starting, check the compressor's oil level.

Drive motor in operating condition "High idle".

Compressor run time min. 10 minutes.

The system should have reached Operating point and steady state

Checkoillevel.Astheinstallationlocationofthecompressorcandifferinpractice(inclinations),it

is recommended that the oil level is checked in both sight glasses. The oil level must be visible in

at least one sight glass.

5.5 Refrigerant charge

5.6 Oil level check

5.7 Shaft seal

CAUTION

Wear personal protective clothing such as goggles and protective

gloves!

ATTENTION Avoidoverllingthesystemwithrefrigerant!

To avoid shifts in concentration, zeotropic refrigerant blends

mustalwaysbeaddedtotherefrigeratingplantinliquidform.

Donotpourliquidrefrigerantthroughthesuctionlinevalveonthe

compressor.

It is not permissible to mix additives with the oil and refrigerant.

ATTENTION After a compressor is replaced, the oil level must be checked again.

If the level is too high, oil must be drained off (risk of oil impact,

reduced performance of the air-conditioning system).

ATTENTION Failure to observe the following instructions can cause loss of

refrigerant and damage to the shaft seal!

INFO The shaft seal seals and lubricates with oil. An oil leakage of

0.05 ml per operating hour is therefore normal. This applies

particularly during the run-in phase (200 - 300 h).

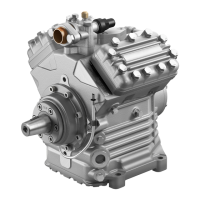

Totrapandcollectleakedoil,theFK40isttedwithaninte-

grated leak oil trapping device with oil reservoir (P.6, Fig. 1).

Loading...

Loading...