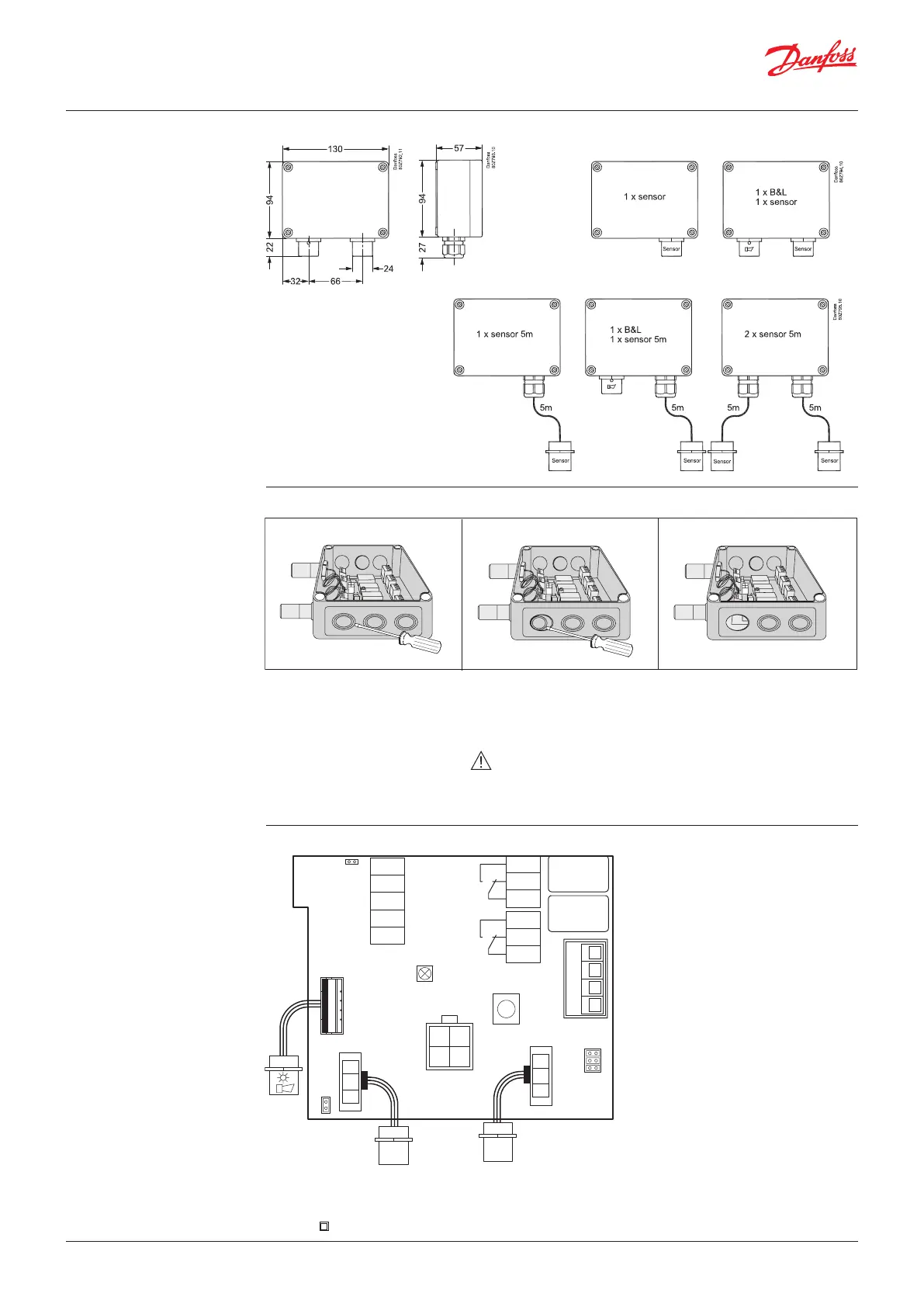

3.4 Dimensions and

appearance

3.5 Cable gland opening

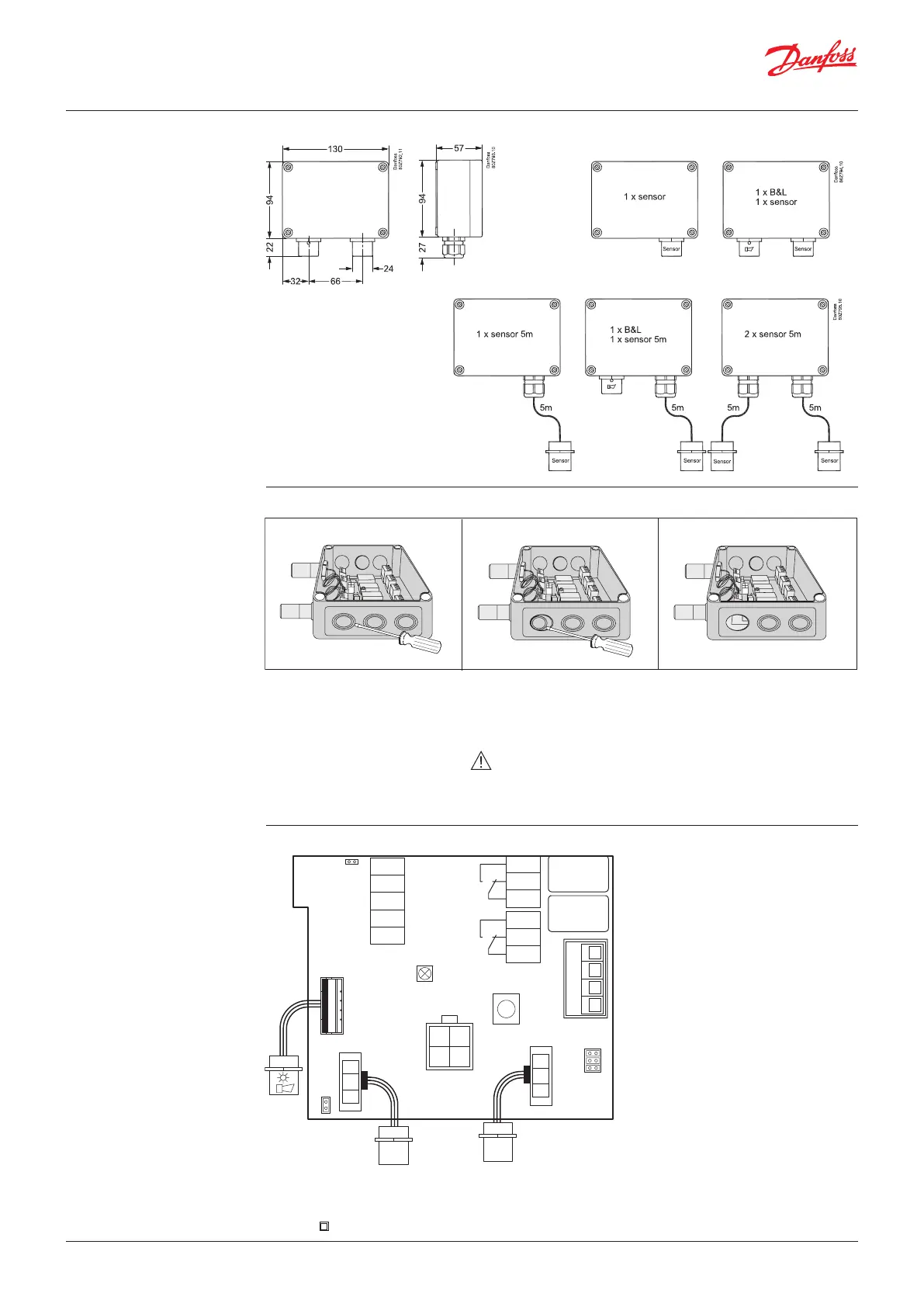

3.6 Board pinout

148H126_01-2018

Hole punching for cable gland:

1. Select the location for the safest

cable entry

2. Use a sharp screwdriver and a

small hammer

3. Place the screwdriver and

hammer with precision while

moving the screwdriver within

a small area until the plastic is

penetrated.

Continue precision punching with

small movements until the round

piece can be pulled out with your

fingers.

WARNING: be very careful not to damage the internal

board components with the screwdriver.

Remove potential burrs and secure

flat surfaces.

Install the cable gland according to

the enclosed guide.

JP5

5

4

2

1

not used

GND

AO_01

DI_01

S&H supply

x1

open: 0-20mA

closed: 0-10V

LED

Yellow/Green/Red

1

2

3

1

2

3

x6

x5

Rel. 3

Rel. 1

x4

4

3

2

1

not used

JP3

JP2

JP1

x3

Ackn.-/Test

button

Sensor 1

Sensor 2

Tool

x9

x2

x8

B&L

JP4

Danfoss

80Z790.1

open: 19200 Baud

closed: 38400 Baud

B-

MODBUS

A+

-

24 V AC/D

+

(critical)

(warning)

Note: For what concern the power supply, please refer to chapter 3.10 Power Conditions and Shielding

Conceptions.

A Class II power supply is recommended

Fig. 1

Fig. 2

Fig. 3

User Guide | Danfoss Gas sensor, type DGS

4 | BC291049702513en-000201 © Danfoss | Climate Solutions | 2022.01

Loading...

Loading...