3.8 Installation Test As DGS is a digital device with self-monitoring,

all internal errors are visible via the LED and

MODBUS alarm messages.

All other error sources often have their origins in

other parts of the installation.

For fast and comfortable installation test we

recommend proceeding as follows.

Optical Check

Right cable type used.

Correct mounting height according to definition

in the section about mounting.

LED status – see DGS trouble shooting.

Functional test (for initial operation and

maintenance)

Functional test is done by pressing the test

button for more than 8 seconds and observing

that all connected outputs (Buzzer, LED, Relay

connected devices) are working properly. After

deactivation all outputs must automatically

return to their initial position.

Zero-point test (if prescribed by local

regulations)

Zero-point test with fresh outdoor air.

A potential zero offset can be read out by use of

the Service Tool.

Trip test with reference gas (if prescribed by

local regulations)

The sensor is gassed with reference gas (for this

you need a gas bottle with pressure regulator

and a calibration adapter).

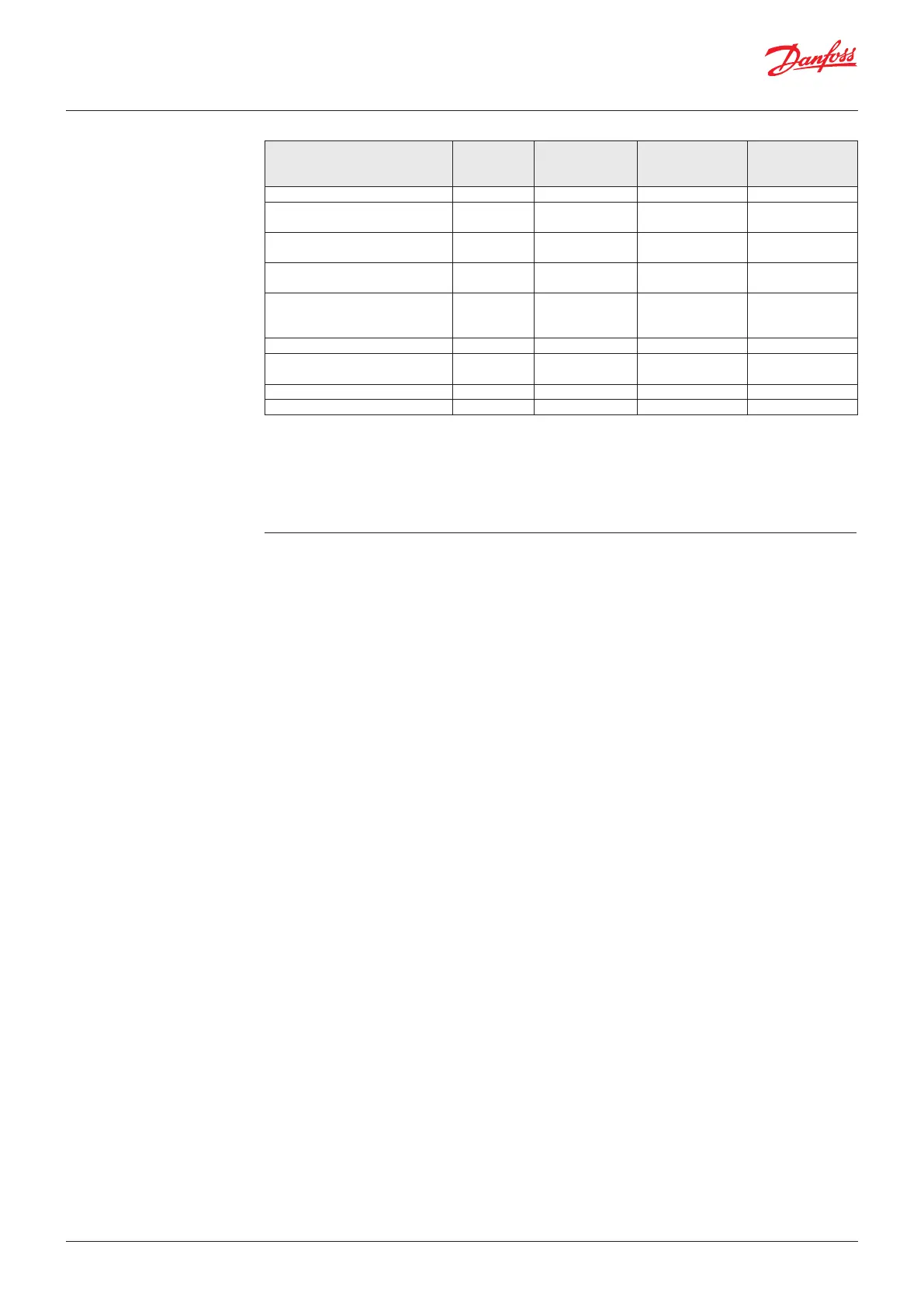

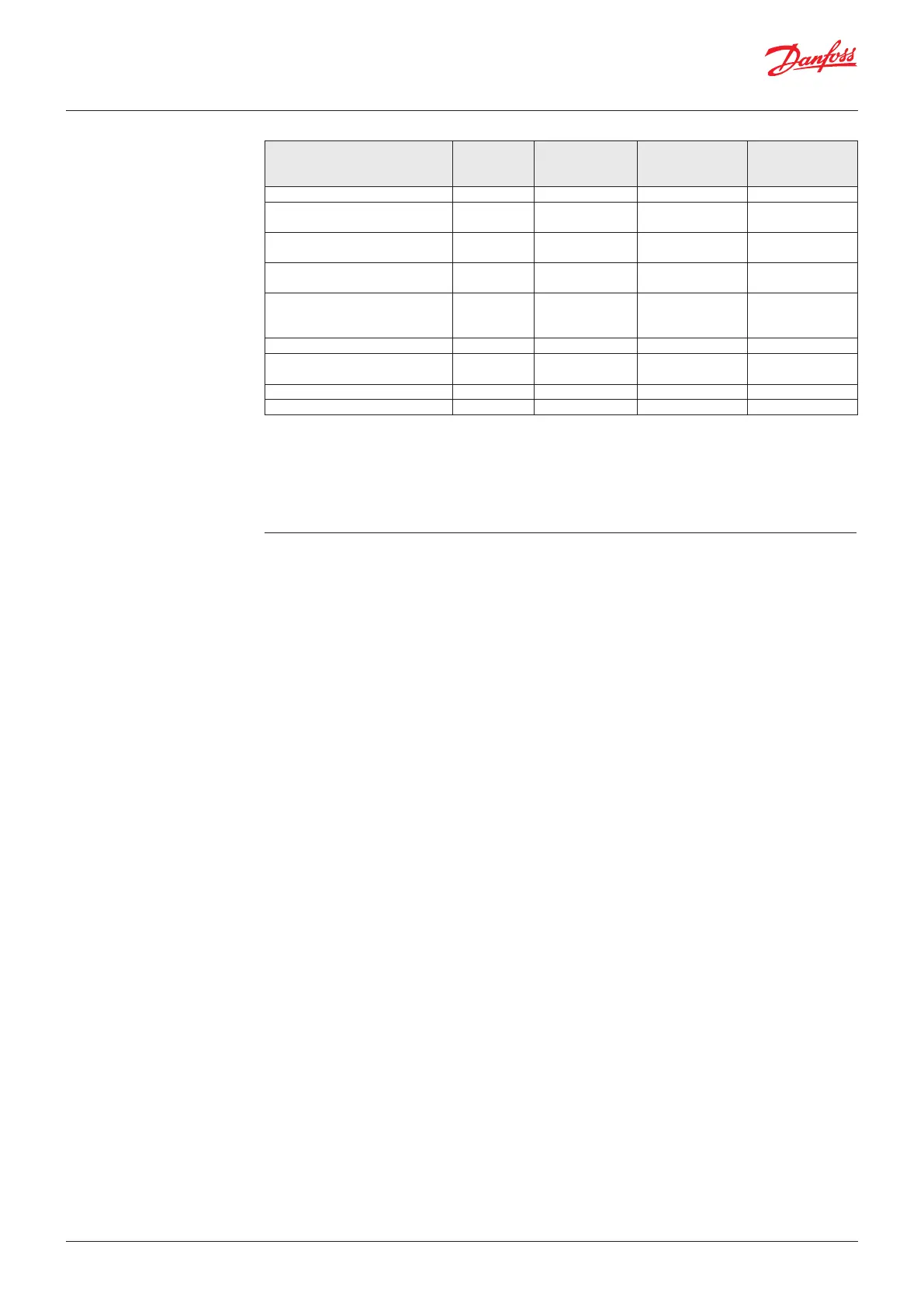

Action Reaction

Buzzer

Reaction

Light

Warning relay 1**

SPDT NO

(Normally Open)

Critical relay 3**

SPDT NC

(Normally closed)

Loss of power to DGS OFF OFF X (closed)

Gas signal < warning alarm

threshold

OFF GREEN

Gas signal > warning alarm

threshold

OFF RED Slow flashing X (closed)

Gas signal > critical alarm

threshold

ON RED Fast flashing X (closed) X (closed)

Gas signal ≥ critical alarm

threshold, but ackn. button

pressed

OFF

(ON after

delay)

RED Fast flashing X (closed)* (open)*

No alarm, no fault OFF GREEN

No fault, but maintenance due OFF GREEN Slow

flashing

Sensor communication error OFF YELLOW

DGS in special mode OFF YELLOW flashing

Alarm thresholds can have the same value, therefore both the relays and the Buzzer and Light can be triggered

simultaneously.

The alarm thresholds have a hysteresis of app. 5%

* whether to include the relay status with the acknowledge function or not is user defined.

** If the DGS has two sensors and the "Room Mode" is configured to "2 rooms", then relay 1 acts as a critical

relay for sensor 1 and relay 3 acts as a critical relay for sensor 2. Both relays are SPDT NC. The Buzzer and Light

operation is independent of the "Room Mode" setting.

In doing so, the set alarm thresholds are

exceeded, and all output functions are activated.

It is necessary to check if the connected output

functions are working correctly (e.g. the horn

sounds, the fan switches on, devices shut down).

By pressing the push-button on the horn, the

horn acknowledgement must be checked. After

removal of the reference gas, all outputs must

automatically return to their initial position.

Other than the trip testing, it is also possible to

perform a functional test by means of calibration.

For further information, please refer to the User

Guide.

Comparing sensor gas type with DGS

specification

The replacement sensor specification must match

the DGS specification.

The DGS software automatically reads the

specification of the connected sensor and

compares with the DGS specification.

This feature increases the user and operating

security.

New sensors are always delivered factory-

calibrated by Danfoss. This is documented by the

calibration label indicating date and calibration

gas. A re-calibration is not necessary during

commissioning if the device is still in its original

packaging (including air-tight protection by

the red protective cap) and if the calibration

certificate has not expired

User Guide | Danfoss Gas sensor, type DGS

6 | BC291049702513en-000201 © Danfoss | Climate Solutions | 2022.01

Loading...

Loading...