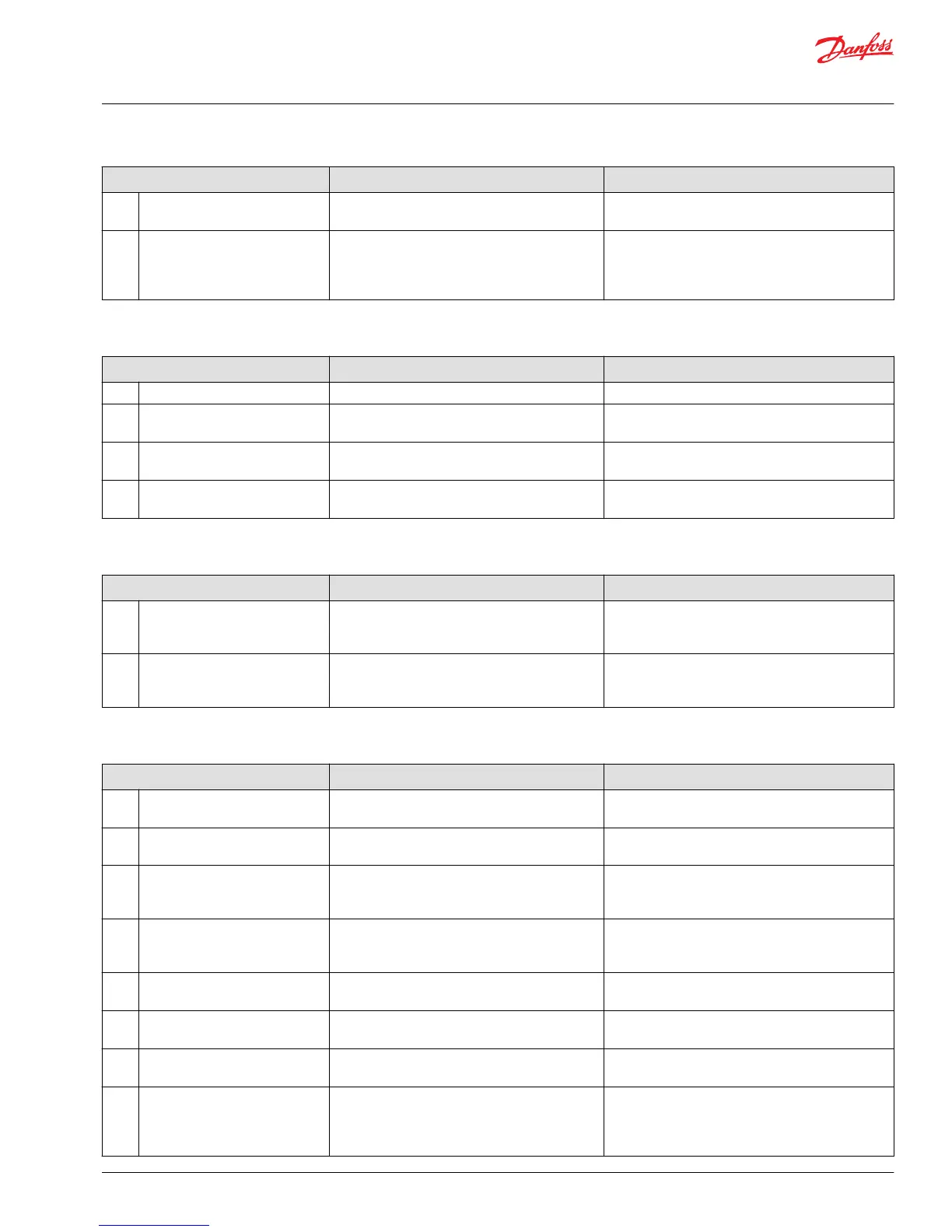

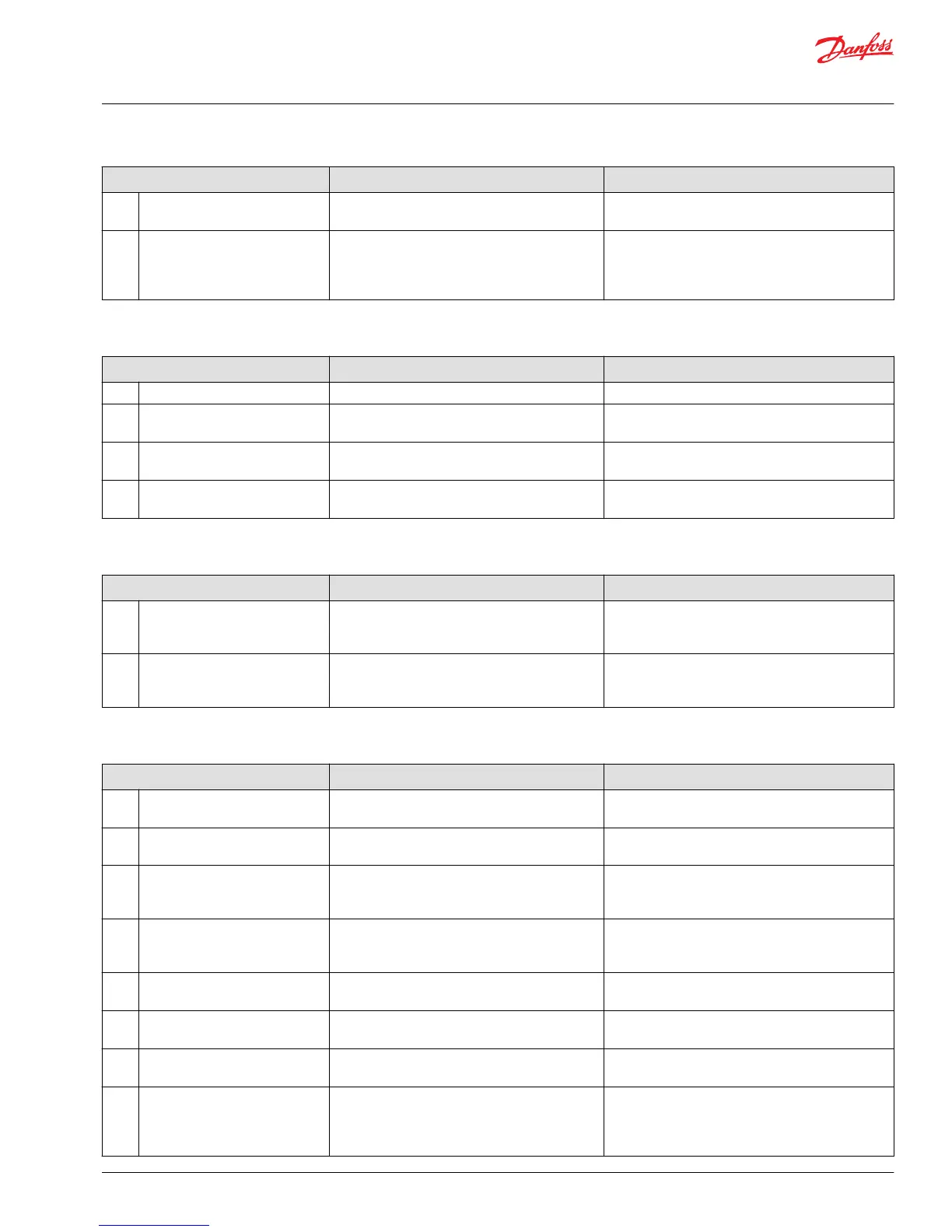

Check Cause Corrective action

5. Air in system Entrained air generates heat under pressure Look for foam or bubbles in reservoir. Check for leaks

on inlet side of charge pump.

6. Internal leakage Excessive internal leakage may overheat the

system.

Install loop flushing defeat option and monitor case

flow. If case flow is excessive, motor may require major

repair. Contact your Danfoss authorized service

center.

Excessive noise or vibration

Check Cause Corrective action

1. Oil level in reservoir Insufficient hydraulic fluid may cause cavitation. Fill reservoir to proper level.

2. Air in system Air bubbles may lead to cavitation. Look for foam or bubbles in reservoir. Check for leaks

on inlet side of charge pump.

3. Shaft coupling Loose shaft coupling may create excess noise. Replace loose shaft coupling. Replace or repair motor

if shaft splines show excessive wear.

4. Shaft alignment Misaligned shafts may create excessive noise and

vibration and can damage motor.

Correct shaft misalignment.

Motor operates normally in one direction only

Check Cause Corrective action

1. Charge pressure If charge pressure is low in one direction, the loop

flushing shuttle spool may be sticking to one side.

Measure charge pressure in forward and reverse. If

pressure drops significantly lower in one direction,

inspect and repair loop flushing shuttle spool.

2. Pressure compensator control If pressure compensator operates in one direction

only, the motor may stay at minimum

displacement in the opposite direction.

Check brake pressure defeat spool. It may be sticking

or receiving an improper signal. Repair spool or

correct input signal.

Improper output speed

Check Cause Corrective action

1. Oil level in reservoir Insufficient hydraulic fluid may reduce system

efficiency.

Fill reservoir to proper level.

2. Threshold setting Improper threshold setting may cause motor to

have wrong displacement for given signal.

Check threshold setting. Refer to Control Service

Manual for adjustment procedure.

3. Pressure compensator setting Improper pressure compensator setting may shift

motor displacement at wrong pressure.

Check pressure compensator setting. Adjust if

necessary. Refer to Control Service Manual for

adjustment procedure.

4. PC spool Pressure compensator spool sticking may shift

motor to improper displacement.

Check pressure compensator spool. Repair or replace

if needed. Refer to Control Service Manual for

adjustment procedure.

5. Control orifices Blocked or restricted orifice may cause motor to

shift improperly.

Remove, inspect and clean all orifices.

6. Control spool Sticky proportional control spool may cause motor

to shift improperly.

Check control spool for proper operation. Repair if

necessary. Refer to control adjustment procedure.

7. Control input signal Improper input signal may cause motor to shift

improperly.

Correct control input signal.

8. Internal leakage Excess internal leakage may cause lower charge

pressure and affect motor performance including

output speed.

Install loop flushing defeat option and measure case

flow. If case flow is excessive, motor may require major

repair. Contact your Danfoss authorized service

center.

Service Manual

H1 Bent Axis Motors, Size 060/080/110/160/210/250 cm3

Troubleshooting

©

Danfoss | August 2018 AX00000025en-US0504 | 31

Loading...

Loading...