Dynamic braking

With the VLT 2800 the dynamic braking quality in an

application can be improved in two ways, either with

the aid of brake resistors or AC braking.

Danfoss offers a complete range of brake resistors for

all VLT 2800 frequency converters.

It is the job of the brake resistor to apply a load to the

intermediate circuit during braking, thereby ensuring

that the brake power can be absorbed by the brake

resistor.

Without a brake resistor, the intermediate circuit volt-

age of the frequency converter would go on rising, until

cutting out for protection. The advantage of using a

brake resistor is that you can brake quickly with large

loads, e.g. on a conveyor belt.

Danfoss has chosen a solution in which the brake re-

sistor is not integrated into the frequency converter.

This gives the user the following advantages:

-

The resistor's cycle time can be selected as

required.

-

The heat generated during braking can be di-

verted outside the panel cabinet, where the

energy can possibly be utilised.

-

No overheating of the electronic compo-

nents, even if the brake resistor is overloa-

ded.

AC braking is an integrated function that is used for

applications in which there is a need for limited dy-

namic braking. The AC braking function makes it pos-

sible to reduce the brake power in the motor instead of

in a brake resistor. The function is intended for appli-

cations where the required braking torque is less than

50% of rated torque. AC braking is selected in par. 400

Brake function.

NB!

The AC brake cannot be used if the re-

quired braking torque is more than 50% of

rated braking torque. In such instances a

brake resistor must be used.

Brake Setup

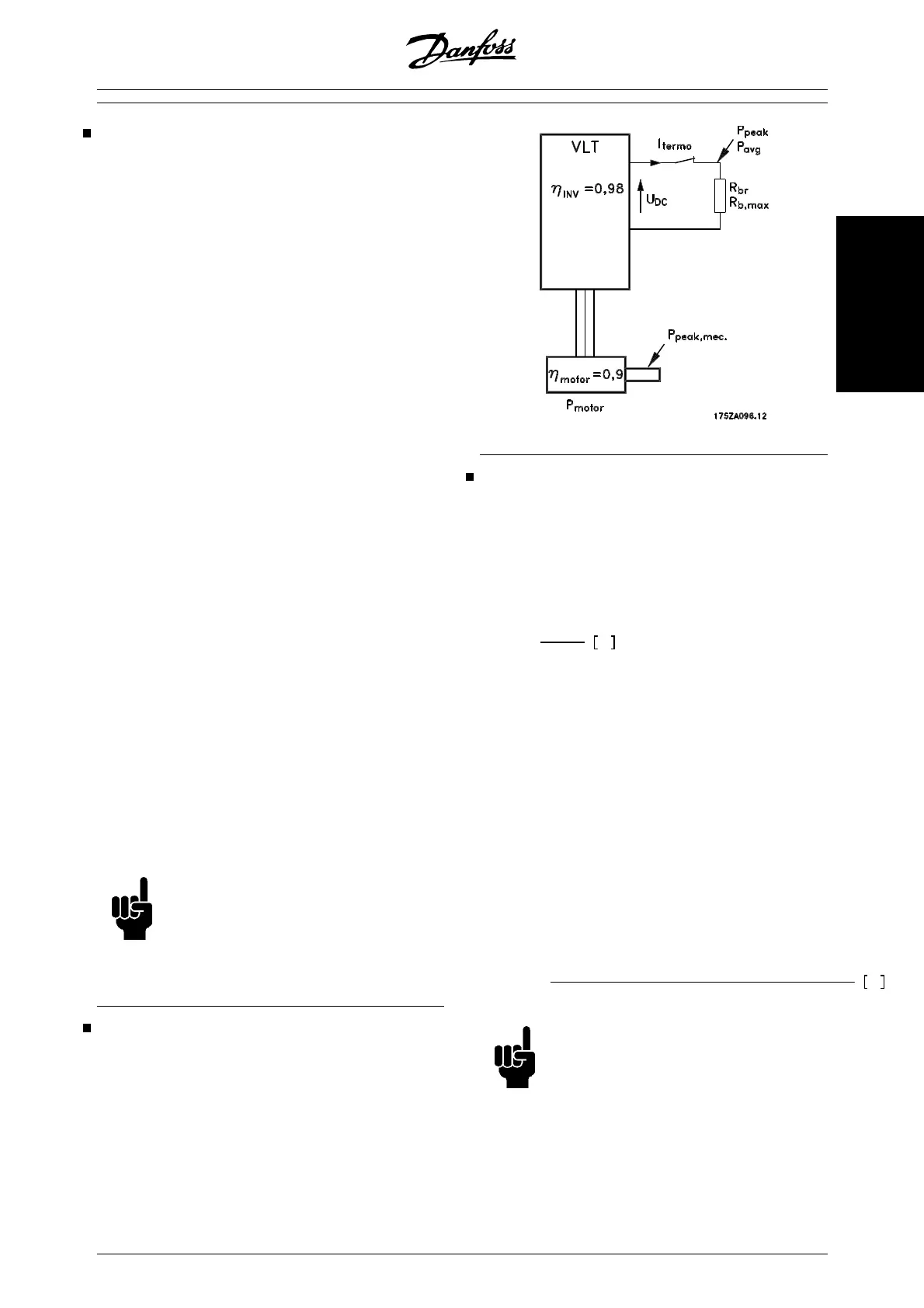

The figure shows a brake Setup with a frequency con-

verter.

In the following paragraphs, expressions and acro-

nyms are used about brake Setups that can be seen

from the figure.

Calculation of brake resistance

The following example and formula only apply to VLT

2800 Series.

To ensure that the frequency converter does not cut

out for safety reasons when the motor brakes, the re-

sistance value is selected on the basis of the peak

braking effect and the intermediate circuit voltage:

R

br

=

U

DC

²

P

PEAK

Ω

It can be seen that the brake resistance depends on

the intermediate circuit voltage (UDC).

With frequency converters that have a mains voltage

of 3 x 380 - 480 Volt, the brake will be active at 770

Volt (UDC); if the frequency converter has a mains

voltage of 3 x 200 - 240 Volt, the brake will be active

at 385 Volt (UDC).

You can also choose to use the brake resistance rec-

ommended by Danfoss (R

REC

). This is a guarantee

that the frequency converter is able to brake at the

highest braking torque (M

BR

). The recommended

brake resistance can be seen from the ordering table

for brake resistors.

R

REC

calculated as:

R

REC

=

U

DC

²

× 100

P

motor

×

Mbr

(

%

)

× η

motor

× η

inv

Ω

NB!

Remember to check that the brake resist-

ance can manage a voltage of 850 Volt or

430 Volt, if Danfoss brake resistors are not

being used.

•

motor

is typically 0.90 and •

INV

is typically 0.98. For 400

Volt and 200 Volt frequency converters, respectively,

R

REC

at 160% braking torque can be written as:

MG.27.E2.02 - VLT is a registered Danfoss trademark 23

Introduction to VLT 2800

Loading...

Loading...