101 = Variable torque medium [3]

If used with centrifugal pumps and fans.

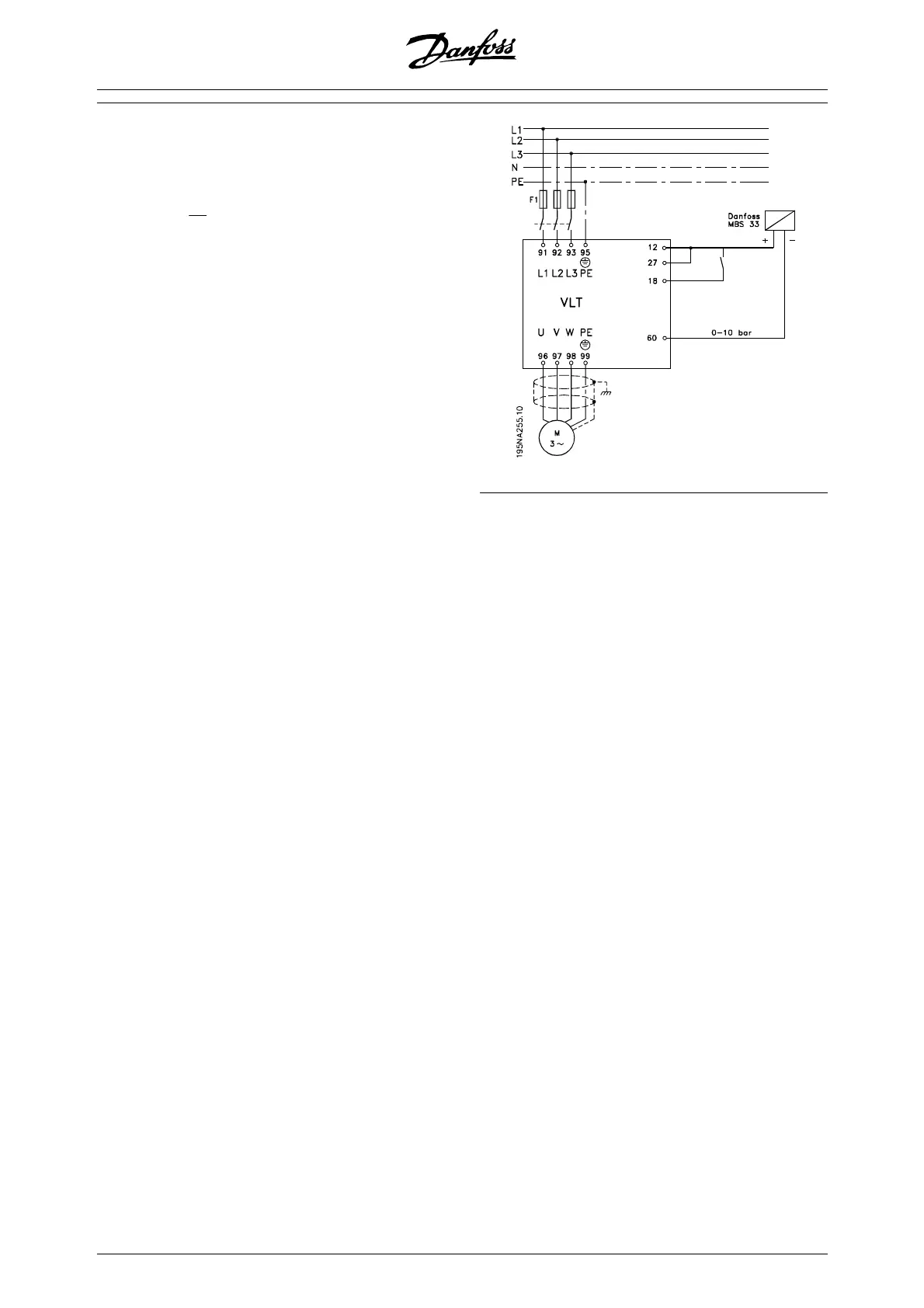

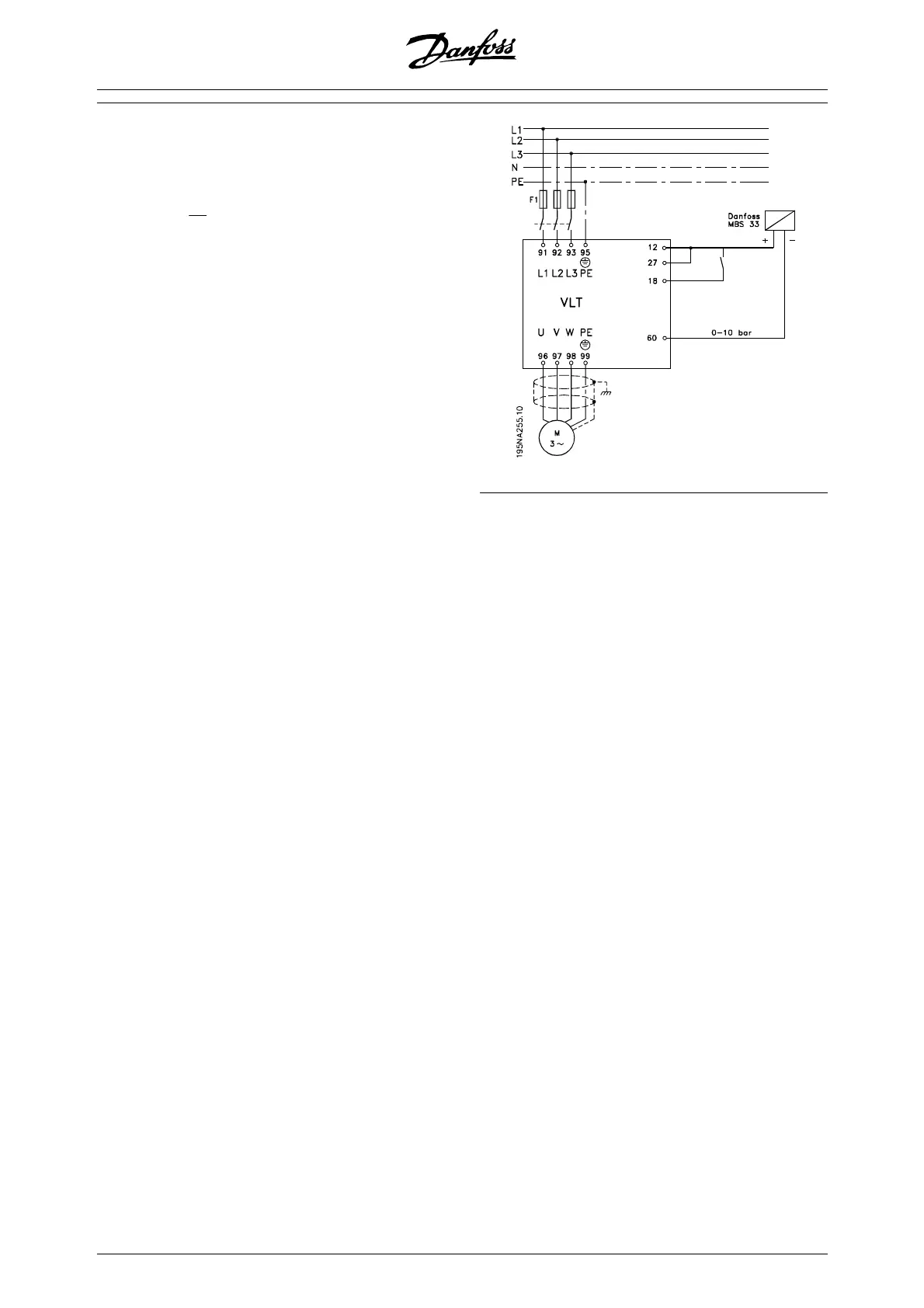

308 = Feedback [2] (for 0-10 V DC transmit-

ters)

or

314 = Feedback [2] (for 4-20 mA transmitters)

414 = Minimum feedback scaling, must be

set to the minimum feedback value

415 = Maximum feedback scaling, must be

set to the maximum feedback value

Example: Pressure transmitter 0-10 bar: 414

= 0 and 415 = 10

416 = Process units: As shown on the local

control panel (example: bar [4])

437 = Normal [0]: The output frequency

should be reduced when the feedback signal

increases

Inverse [1]: The output frequency should in-

crease when the feedback signal increases

440 = Proportional gain (P-gain) 0.3-1.0 (ex-

perienced value)

441 = Integration time (I-time) 3-10 sec. (ex-

perienced value)

442 = Differentiation time (D-time) 0-10 sec.

(experienced value)

205 = Max. reference is to be set equal to

parameter 415 (example: 10 bar)

215 = Preset reference 1. Set the preset ref-

erence to the wanted min. reference value

(example: 5 bar)

(Parameter 205 and 215 are shown in the

process unit chosen in parameter 416).

The value in brackets [ ] are data values cor-

responding to the wanted function. Example:

Parameter 308 Feedback signal = [2]

If the motor is supposed to always run at a

minimum speed, a such can be selected in

parameter 204 = output frequency low limit.

(For pump works it is typically 15-20 Hz).

With the above connections and settings all

normal pump and fan applications will work

properly. In certain cases it might be neces-

sary to optimize the PID-controllerr (parame-

ter 440, 441 and 442) beyond the mentioned

experienced values.

58 MG.27.E2.02 - VLT is a registered Danfoss trademark

Loading...

Loading...