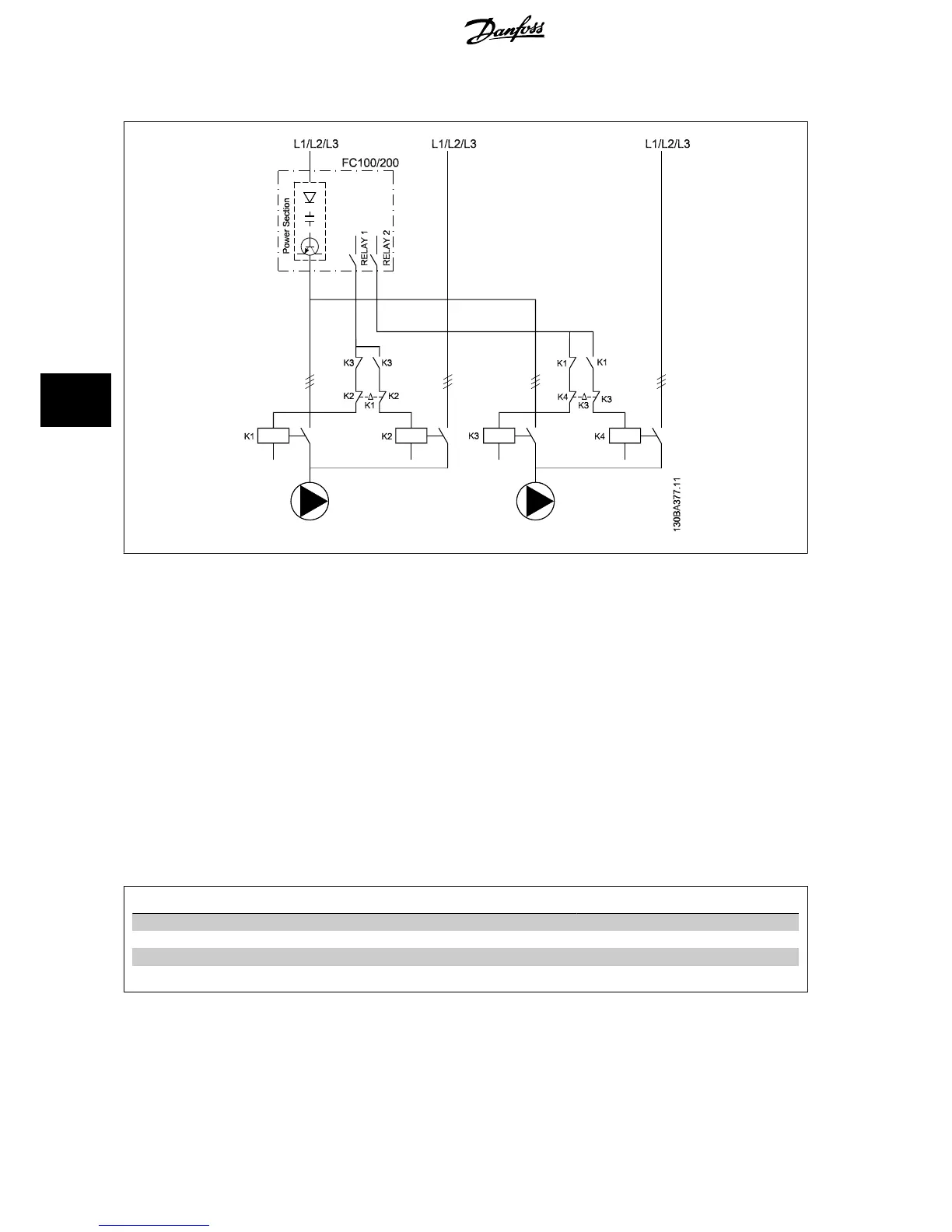

6.1.12 Lead Pump Alternation Wiring Diagram

Every pump must be connected to two contactors (K1/K2 and K3/K4) with a mechanical interlock. Thermal relays or other motor protection devices must

be applied according to local regulation and/or individual demands.

• RELAY 1 (R1) and RELAY 2 (R2) are the built-in relays in the frequency converter.

• When all relays are de-energized, the first built in relay to be energized will cut in the contactor corresponding to the pump controlled by the

relay. E.g. RELAY 1 cuts in contactor K1, which becomes the lead pump.

• K1 blocks for K2 via the mechanical interlock preventing mains to be connected to the output of the frequency converter (via K1).

• Auxiliary break contact on K1 prevents K3 to cut in.

• RELAY 2 controls contactor K4 for on/off control of the fixed speed pump.

• At alternation both relays de-energizes and now RELAY 2 will be energized as the first relay.

6.1.13 Start/Stop Conditions

Commands assigned to digital inputs. See

Digital Inputs

, par.5-1*.

Variable speed pump (lead) Fixed speed pumps

Start (SYSTEM START /STOP) Ramps up (if stopped and there is a demand) Staging (if stopped and there is a demand)

Lead Pump Start Ramps up if SYSTEM START is active Not affected

Coast (EMERGENCY STOP) Coast to stop Cut out (built in relays are de-energized)

Safety Interlock Coast to stop Cut out (built in relays are de-energized)

Function of buttons on Local Control Panel

6 Application Examples VLT

®

AQUA Drive Design Guide

166

MG.20.N5.02 - VLT

®

is a registered Danfoss trademark

6

Loading...

Loading...