3.2 Efficiency

Efficiency of VLT AQUA (η

VLT

)

The load on the frequency converter has little effect on its efficiency. In general, the efficiency is the same at the rated motor frequency f

M,N

, even if the

motor supplies 100% of the rated shaft torque or only 75%, i.e. in case of part loads.

This also means that the efficiency of the frequency converter does not change even if other U/f characteristics are chosen.

However, the U/f characteristics influence the efficiency of the motor.

The efficiency declines a little when the switching frequency is set to a value of above 5 kHz. The efficiency will also be slightly reduced if the mains

voltage is 480 V, or if the motor cable is longer than 30 m.

Efficiency of the motor (η)

MOTOR

The efficiency of a motor connected to the frequency converter depends on magnetising level. In general, the efficiency is just as good as with mains

operation. The efficiency of the motor depends on the type of motor.

In the range of 75-100% of the rated torque, the efficiency of the motor is practically constant, both when it is controlled by the frequency converter

and when it runs directly on mains.

In small motors, the influence from the U/f characteristic on efficiency is marginal. However, in motors from 11 kW and up, the advantages are significant.

In general, the switching frequency does not affect the efficiency of small motors. Motors from 11 kW and up have their efficiency improved (1-2%). This

is because the sine shape of the motor current is almost perfect at high switching frequency.

Efficiency of the system (η

SYSTEM

To calculate the system efficiency, the efficiency of VLT AQUA (η

VLT

) is multiplied by the efficiency of the motor (η

MOTOR

):

η

SYSTEM

) = η

VLT

x η

MOTOR

Calculate the efficiency of the system at different loads based on the graph above.

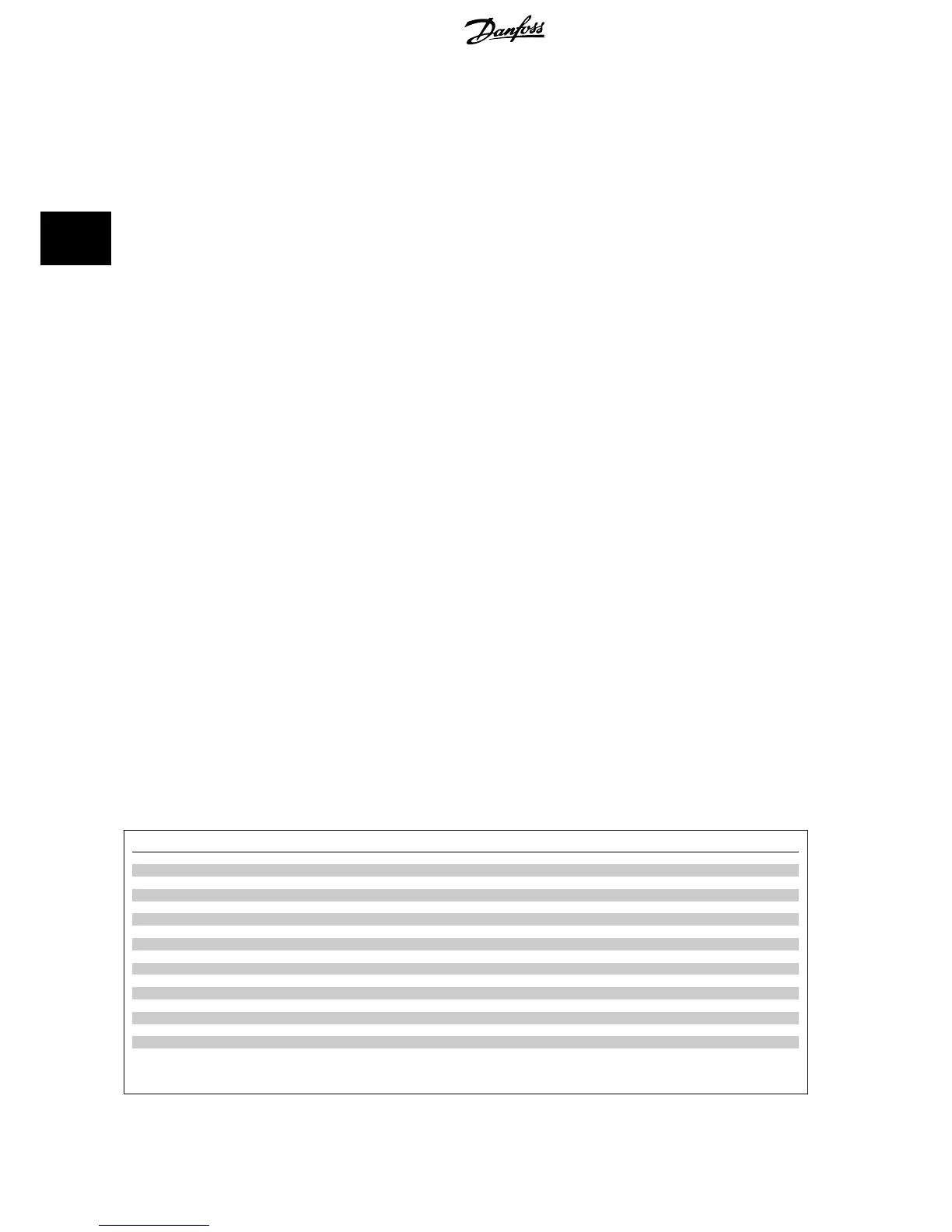

3.3 Acoustic noise

The acoustic noise from the frequency converter comes from three sources:

1. DC intermediate circuit coils.

2. Integral fan.

3. RFI filter choke.

The typical values measured at a distance of 1 m from the unit:

Enclosure

At reduced fan speed (50%) [dBA] *** Full fan speed [dBA]

A2 51 60

A3 51 60

A5 54 63

B1 61 67

B2 58 70

B3 59.4 70.5

B4 53 62.8

C1 52 62

C2 55 65

C3 56.4 67.3

C4 --

D1+D3 74 76

D2+D4 73 74

E1/E2 * 73 74

E1/E2 ** 82 83

F1/F2/F3/F4 78 80

* 315 kW, 380-480 VAC and 450/500 kW, 525-690 VAC only!

** Remaining E1+E2 power sizes.

*** For D, E and F sizes, reduced fan speed is at 87%, measured at 200 V.

3 VLT AQUA Selection VLT

®

AQUA Drive Design Guide

54

MG.20.N5.02 - VLT

®

is a registered Danfoss trademark

3

Loading...

Loading...