3.6 Setting Address Switches

NOTICE

Switch o the power supply before changing the address

switches. The address change comes into eect at the

next power-up.

The address switches enable setting of baudrate and node

ID:

•

Switches 8 and 7 arefor setting the baudrate for

either: 125, 250, or 500 Kbps.

•

Switches 6–1 are for setting the node address in

the range 1–62.

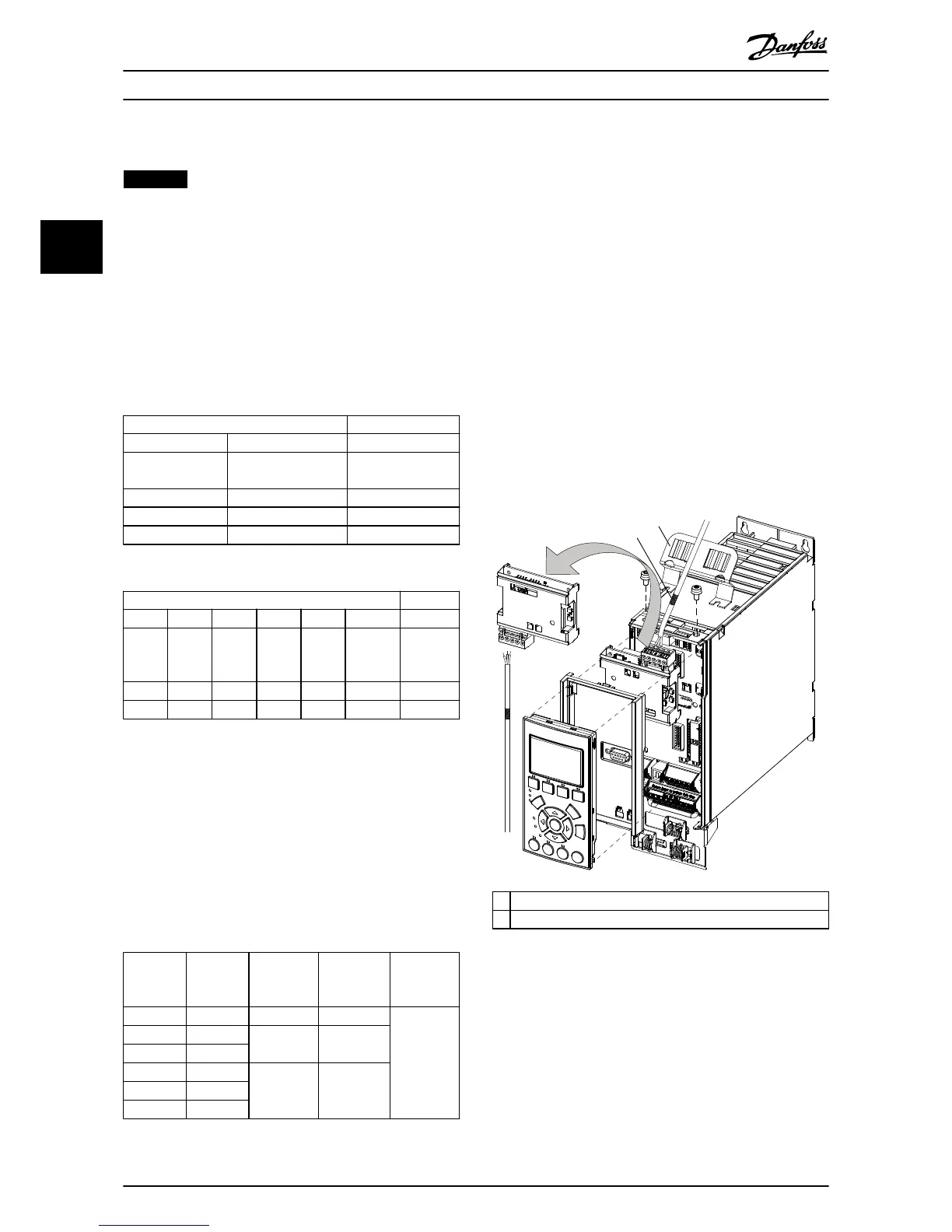

Switch Baudrate

8 7

On On Parameter 10-01 Bau

d Rate Select

On O 500 kbps

On On 250 kbps

On O 125 kbps

Table 3.1 Switches 8 and 7

Switch Node ID

6 5 4 3 2 1

On On On On On On Parameter

10-02 MAC

ID

On On On On On O 62

O O O O O On 1

Table 3.2 Switches 6–1

When both switch 8 and 7are set to ON, select baudrates

via parameter 10-01 Baud Rate Select: 10, 20, 50, 100, 125,

250, or 500 kbps.

When switches 6–1 are set to ON, select node ID via

parameter 10-02 MAC ID in the range: 1–127

3.7

Electrical Installation

3.7.1 Cable Specications

Baudrate

[kbps]

Maximum

cable

length [m]

Resistance

[mΩ/m]

Cable cross-

section

[mm

2

]

Termination

resistor [Ω]

500 100 <60 0.34–0.6

120

250 250

<40 0.5–0.6

125 500

50 1000

<26 0.75–0.820 2500

10 5000

Table 3.3 Cable Specications

3.7.2 Wiring Procedures

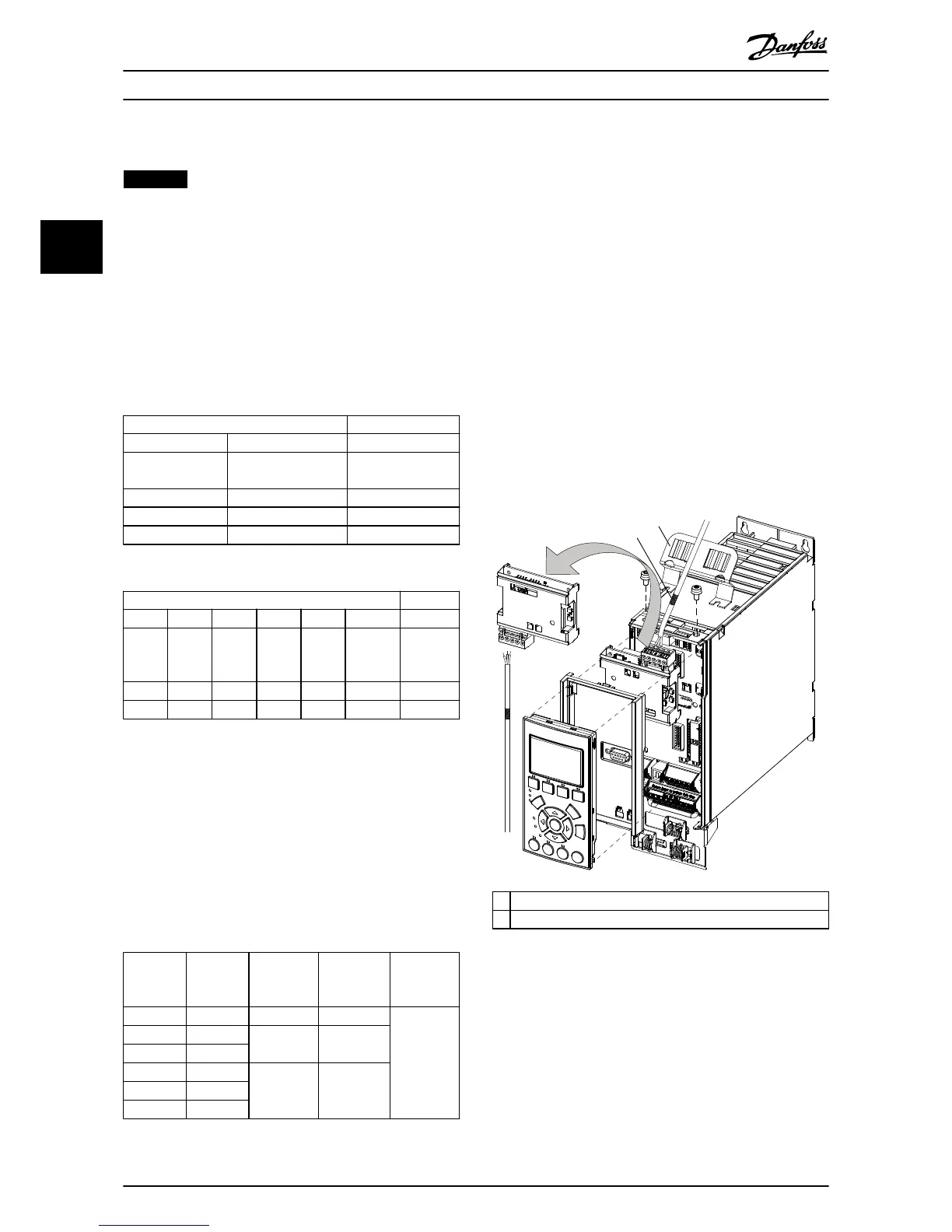

Wiring procedure for enclosure sizes A1–A3

1. Mount the eldbus connector on the eldbus

option (CAN_L, Drain, CAN_H). For top cable

entry, mount the supplied EMC bracket on top of

the frequency converter with 2 screws.

2. Prepare the eldbus cable by stripping a section

of the cable insulation, so that the cable screen

contacts the EMC bracket. Keep the unshielded

wire as short as possible. For cable specications,

refer to chapter 3.7.1 Cable Specications.

3. Connect the eldbus cable wires to the terminals

according to the colour code of the wires, see

Illustration 3.6.

4. To establish mechanical xation and electrical

contact between cable screen and ground,

position the stripped cable between the spring

loaded metal clamps.

Loading...

Loading...