1.

Select Auto On mode via LCP/GLCP.

2. Switch on digital input 29 to start homing. The

motor will rotate and move the conveyor cart to

the home position.

3. Wait until digital out 42 is changed to high level.

4. Swtich off digital input 29 to stop homing.

4.6.5 Positioning

Set the parameters for positioning as described in

Table 4.6.

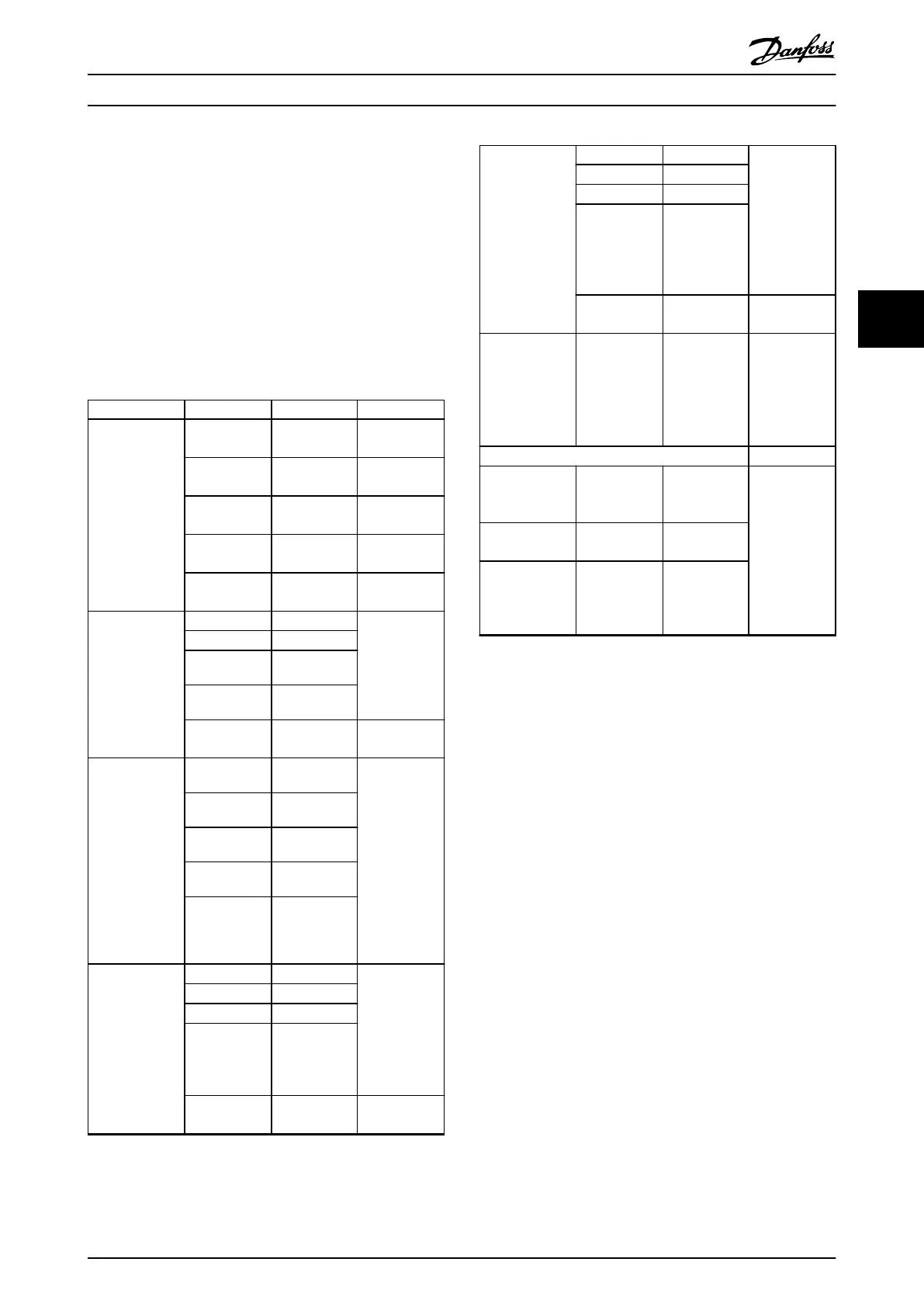

Parameter Array Index Value Description

Parameter 37-02

Pos. Target

0 5800 UU Position 0,

inlet 1.

1 3800 UU Position 1,

inlet 2.

2 1800 UU Position 2,

inlet 3.

3 2300 UU Position 3,

outlet.

4–7 *0 UU Not used in

this example.

Parameter 37-03

Pos. Type

0 *[0] Absolute

1 *[0] Absolute

2 *[0] Absolute

3 *[0] Absolute

4–7 *[0] Absolute Not used in

this example.

Parameter 37-04

Pos. Velocity

0 300 RPM The cart is full

to outlet, but

empty to inlet.

It means the

load to Pos3 is

larger than to

Pos0/1/2. So

we set Pos3’s

velocity to be

a little lower

than others.

1 300 RPM

2 300 RPM

3 120 RPM

4-7 *100 RPM

Parameter 37-05

Pos. Ramp Up

Time

0 1000 ms Considering

the velocity

setting, set the

ramp-up time

of position 3

to be

relatively long.

1 1000 ms

2 1000 ms

3 2000 ms

4-7 *5000 ms Not used in

this case.

Parameter 37-06

Pos. Ramp Down

Time

0 1000 ms Considering

the velocity

settings, set

the ramp-

down time of

position 3 to

be relatively

long.

1 1000 ms

2 1000 ms

3 2000 ms

4–7 *5000 ms Not used in

this example.

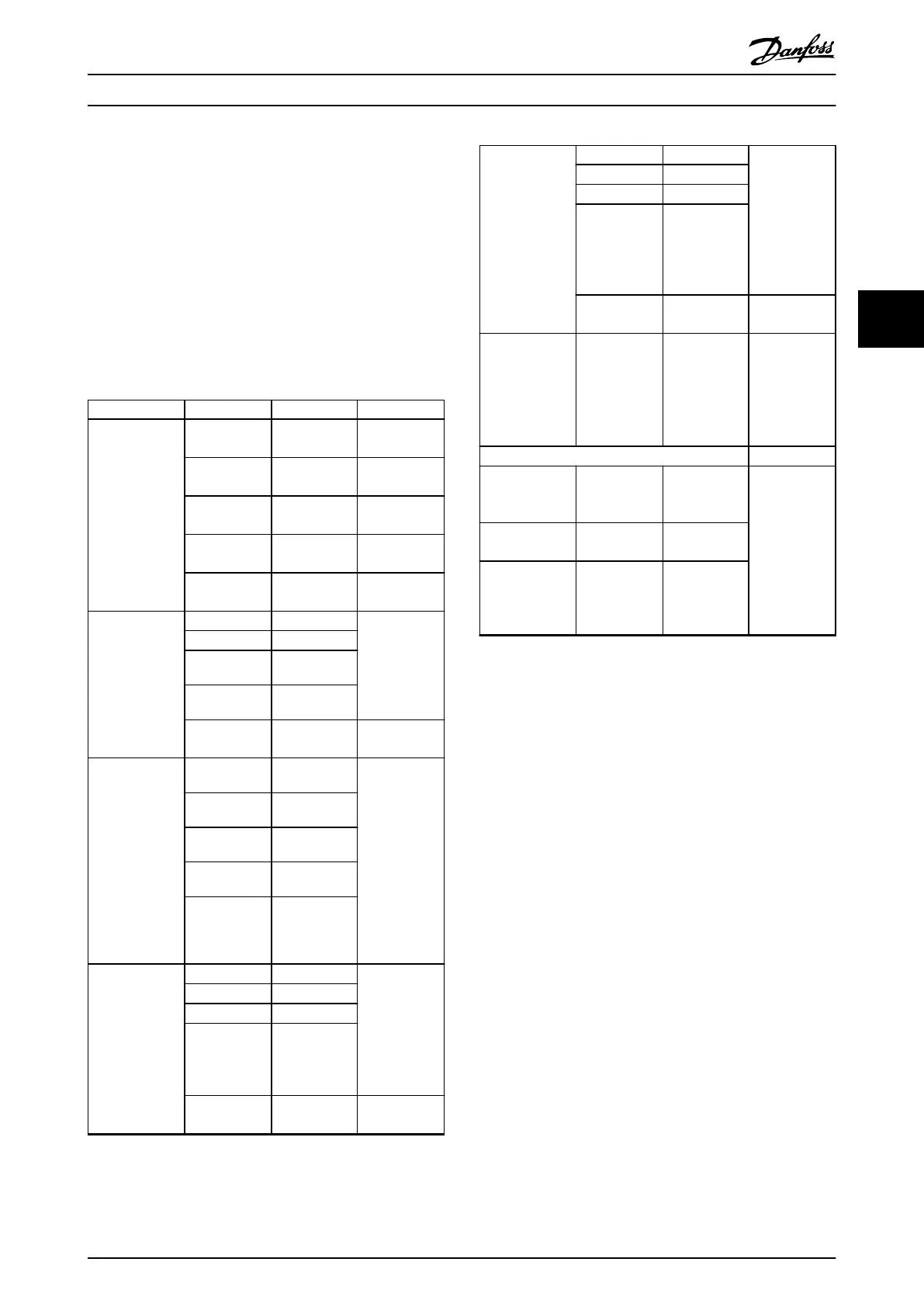

Parameter 33-47

Target Position

Window

– 20 UU Set to a value

based on the

actual

situation of

the

application.

PID Settings

7-33 Process PID

Proportional

Gain

– 0.5 These are only

empirical

settings,

should be

adjusted

following the

situation of

commissioning

in real system.

7-34 Process PID

Integral Time

– 20

7-35 Process PID

Differentiation

Time

– 0

Table 4.6 Positioning Parameter Set-up

Operating procedure of positioning

Go to position 0 to get a pallet:

1. Switch off digital inputs 19 and 27 to select

position 0.

2. Swith on digital 18 to move to position 0.

3. Wait until digital out 42 is turned on, which

means the target position is reached. Make sure

the pallet transfer starts after the position is

reached. Otherwise, adjust the system or

parameters.

4. Switch off digital input 18 to stop positioning.

5. Wait until the pallet is transferred to the cart.

Go to position 1 to get a pallet:

1. Switch on digital input 19 and switch off digital

input 27 to select position 1.

2. Swith on digital 18 to move to position 1.

3. Wait until digital out 42 is turned on, which

means the target position is reached. Make sure

the pallet transfer starts after the position is

reached. Otherwise, adjust the system or

parameters.

4. Switch off digital input 18 to stop positioning.

5. Wait until the pallet is transferred to the cart.

Positioning Control

Application Guide

MG06E102 Danfoss A/S © 11/2014 All rights reserved. 19

4 4

Loading...

Loading...