N O T I C E

Electronic thermal protection (ETR) is used in combination with a VZH Danfoss compressor.

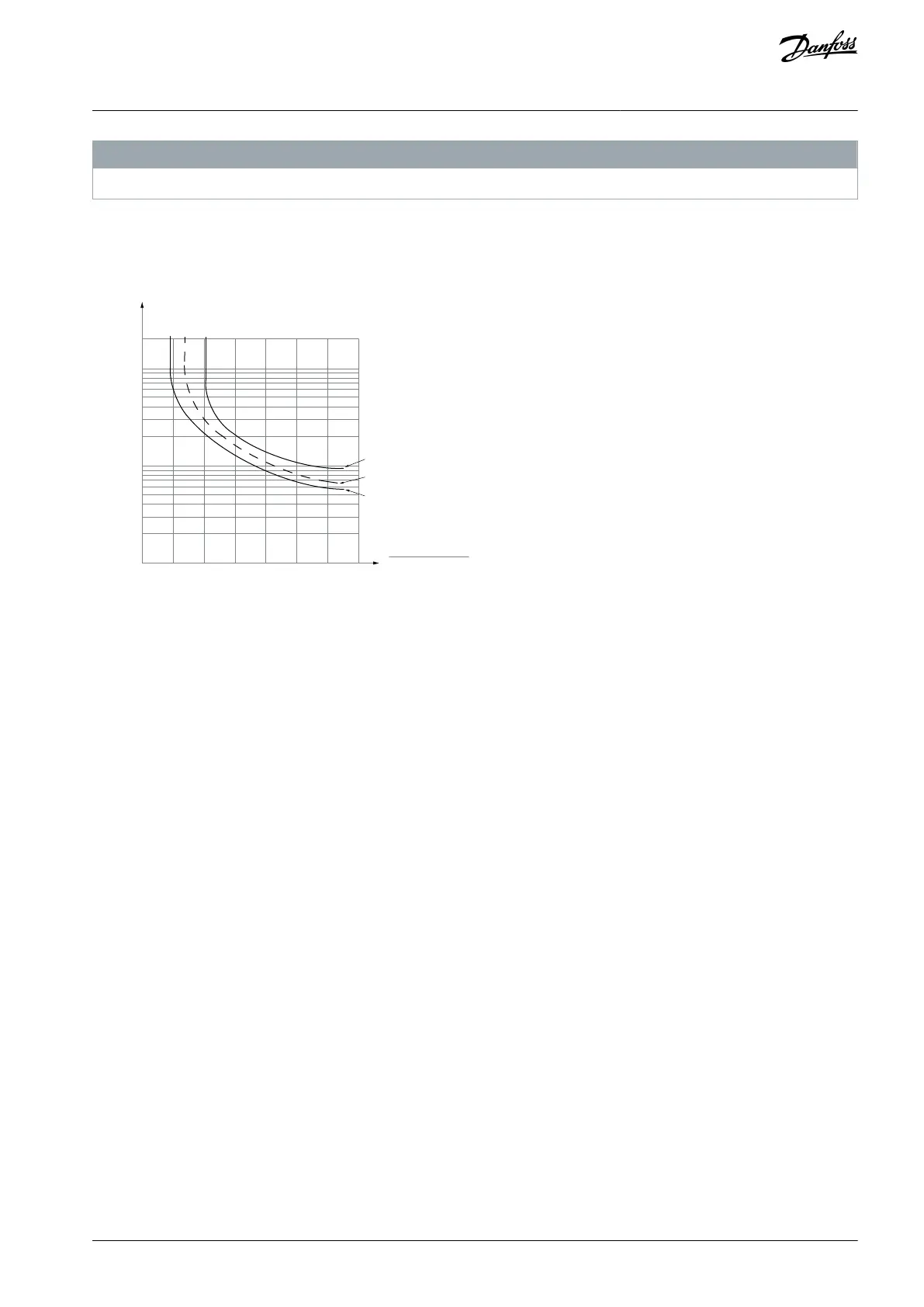

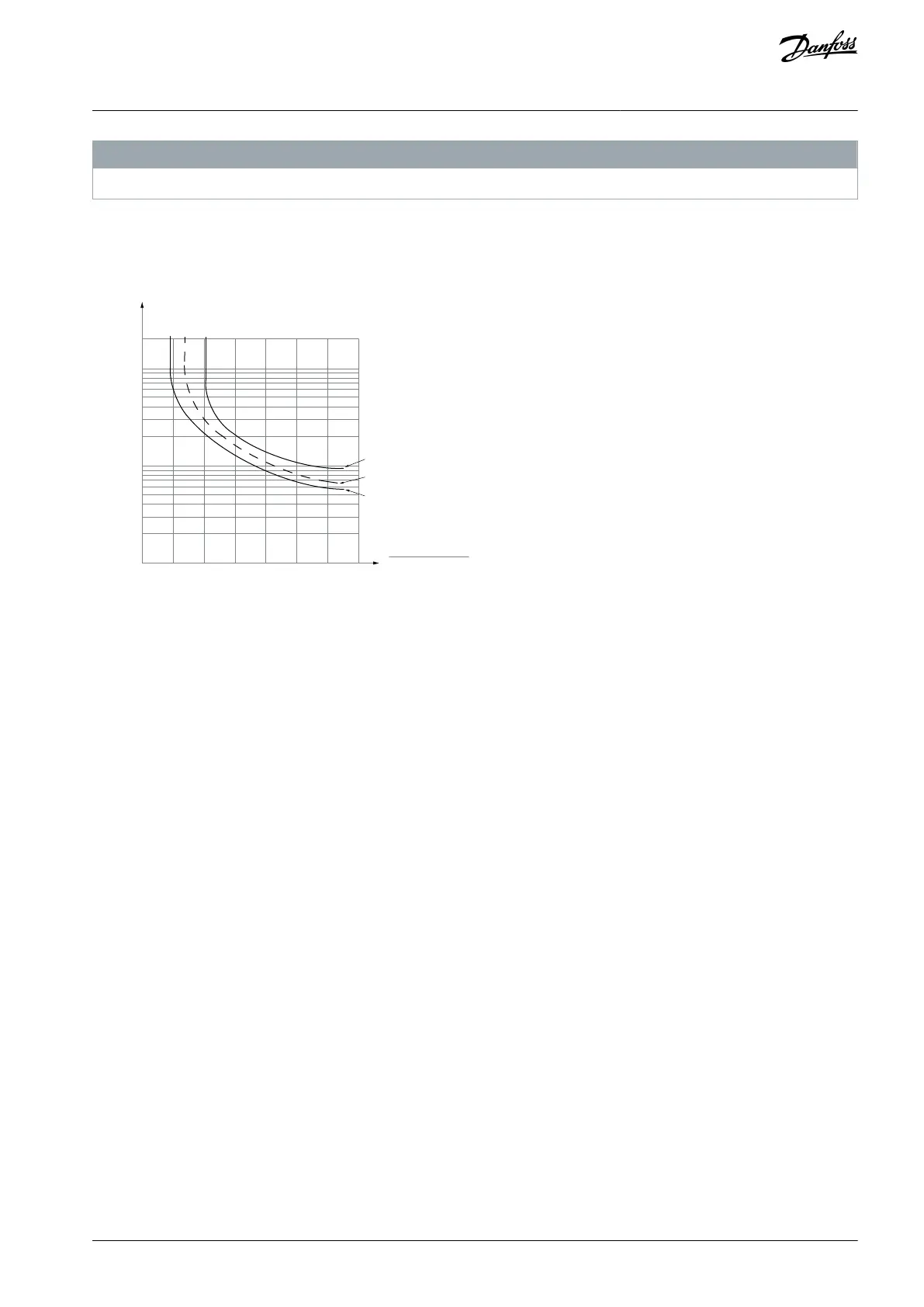

ETR calculates motor temperature by measuring current, frequency, and operating time. The drive shows the thermal load on the

motor in percentage and can issue a warning at a programmable overload setpoint. Programmable options at the overload allow

the drive to stop the motor, reduce output, or ignore the condition. Even at low speeds, the drive meets I2t Class 20 electronic

motor overload standards.

1000

600

t [s]

e75za052.13

I

M,N

(parameter 1-24)

I

M

f

OUT

= 2 x f

M,N

(parameter 1-23)

f

OUT

= 1 x f

M,N

f

OUT

= 0.2 x f

M,N

Illustration 8: ETR Characteristics

The X-axis shows the ratio between I

motor

and I

motor

nominal. The Y-axis shows the time in seconds before the ETR cuts off and trips

the drive. The curves show the characteristic nominal speed at twice the nominal speed and at 0.2 x the nominal speed. At lower

speed, the ETR cuts off at lower heat due to less cooling of the motor. In that way, the motor is protected from being overheated

even at low speed. The ETR feature calculates the motor temperature based on actual current and speed. The calculated tempera-

ture is visible as a readout parameter in parameter 16-18 Motor Thermal.

3.2.2.3 Built-in PID Controller

The built-in proportional, integral, derivative (PID) controller eliminates the need for auxiliary control devices. The PID controller

maintains constant control of closed-loop systems where regulated pressure, flow, temperature, or other system requirements must

be maintained.

The drive can use 2 feedback signals from 2 different devices, allowing the system to be regulated with different feedback require-

ments. The drive makes control decisions by comparing the 2 signals to optimize system performance.

3.2.2.4 Automatic Restart

The drive can be programmed to restart the motor automatically after a minor trip, such as momentary power loss or fluctuation.

This feature eliminates the need for manual resetting and enhances automated operation for remotely controlled systems. The

number of restart attempts and the duration between attempts can be limited.

3.2.2.5 Flying Start

Flying start allows the drive to synchronize with an operating motor rotating at up to full speed in either direction. This prevents

trips due to overcurrent draw. It minimizes mechanical stress to the system since the motor receives no abrupt change in speed

when the drive starts.

3.2.2.6 Frequency Bypass

In some applications, the system can have operational speeds that create a mechanical resonance. This mechanical resonance can

generate excessive noise and possibly damage mechanical components in the system. The drive has 4 programmable bypass-fre-

quency bandwidths (parameters 4-60 to 4-63). The bandwidths allow the motor to step over speeds that induce system resonance.

3.2.2.7 Motor Preheat

Instead of using a space heater, Danfoss provides motor preheat functionality. To preheat a motor in a cold or damp environment, a

small amount of DC current can be trickled continuously into the motor to protect it from condensation and cold starts.

AJ330233902305en-000201 / 130R0596 | 17Danfoss A/S © 2021.05

Product Overview

VLT® Compressor Drive CDS 803

Design Guide

Loading...

Loading...