3-71 Ramp 4 Ramp up Time

Range: Function:

Size

related*

[ 0.01 -

3600.00

s]

Enter the ramp-up time, i.e. the

acceleration time from 0 RPM to the rated

motor speed n

s

. Choose a ramp-up time

such that the output current does not

exceed the current limit in 4-18 Current

Limit during ramping. The value 0.00

corresponds to 0.01 s in speed mode. See

ramp-down time in 3-72 Ramp 4 Ramp

Down Time.

Par

. 3 − 71 =

t

acc

s

x

n

s

RPM

ref

RPM

3-72 Ramp 4 Ramp Down Time

Range: Function:

Size

related*

[ 0.01 -

3600.00

s]

Enter the ramp-down time, i.e. the

deceleration time from the rated motor

speed n

s

to 0 RPM. Choose a ramp-down

time such that no over-voltage arises in the

inverter due to regenerative operation of

the motor, and such that the generated

current does not exceed the current limit

set in 4-18 Current Limit. The value 0.00

corresponds to 0.01 s in speed mode. See

ramp-up time in 3-71 Ramp 4 Ramp up

Time.

Par

. 3 − 72 =

t

dec

s

x

n

s

RPM

ref

RPM

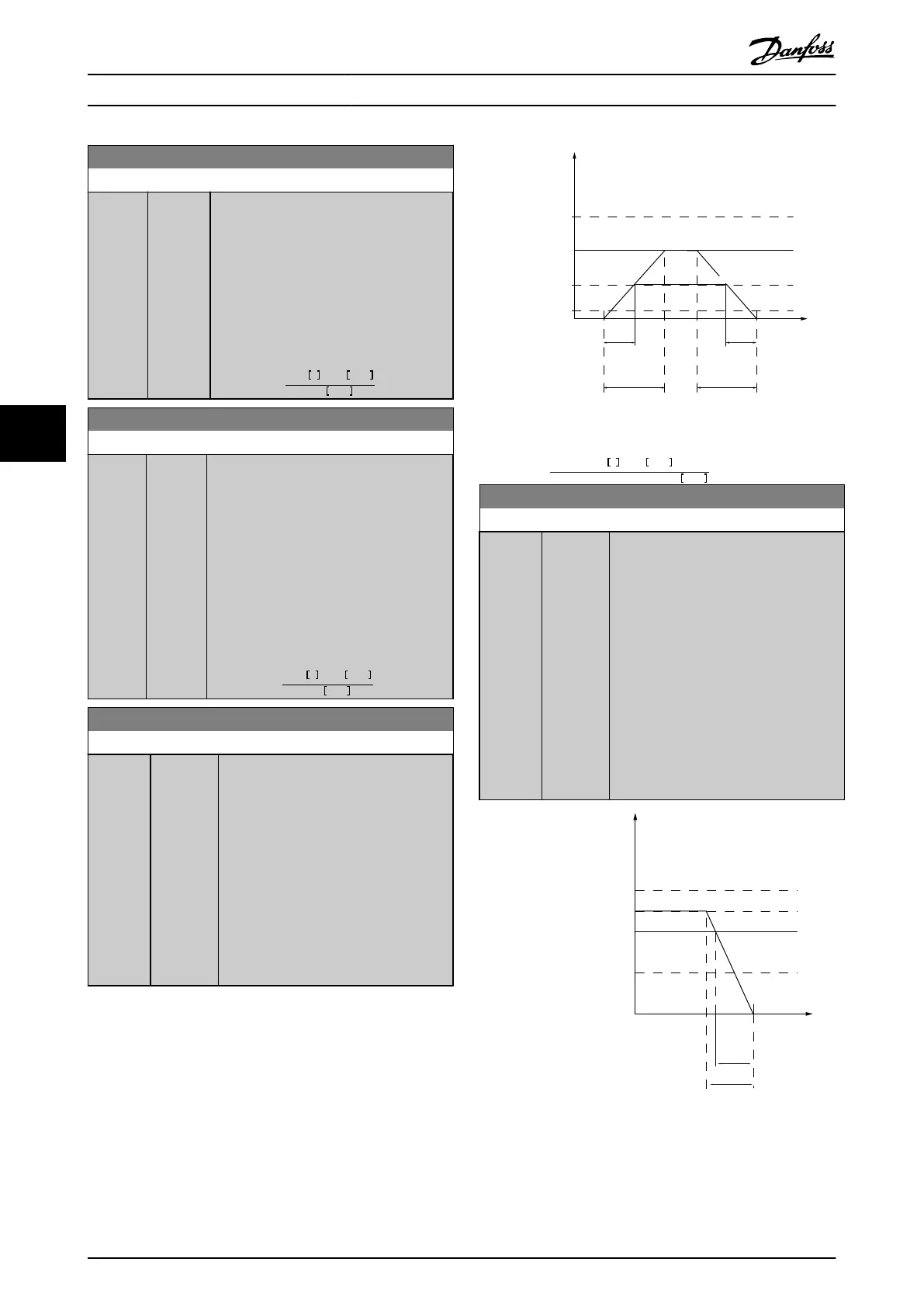

3-80 Jog Ramp Time

Range: Function:

Size

related*

[0.01 -

3600.00 s]

Enter the jog ramp time, i.e. the

acceleration/deceleration time between 0

RPM and the rated motor frequency n

s

.

Ensure that the resultant output current

required for the given jog ramp time

does not exceed the current limit in

4-18 Current Limit. The jog ramp time

starts upon activation of a jog signal via

the LCP, a selected digital input, or the

serial communication port. When jog

state is disabled then the normal

ramping times are valid.

130BA070.10

Time

P 3-80

RPM

P 4-13 RPM

high limit

P 1-25

Motor speed

Jog speed

P 3-19

P 3-80

Ramp up

(acc)

Ramp down

(dec)

t jog t jog

P 4-11 RPM

low limit

Illustration 6.4

Par

. 3 − 80 =

t

jog

s

x

n

s

RPM

Δ

jog

speed

(

par

. 3 − 19

)

RPM

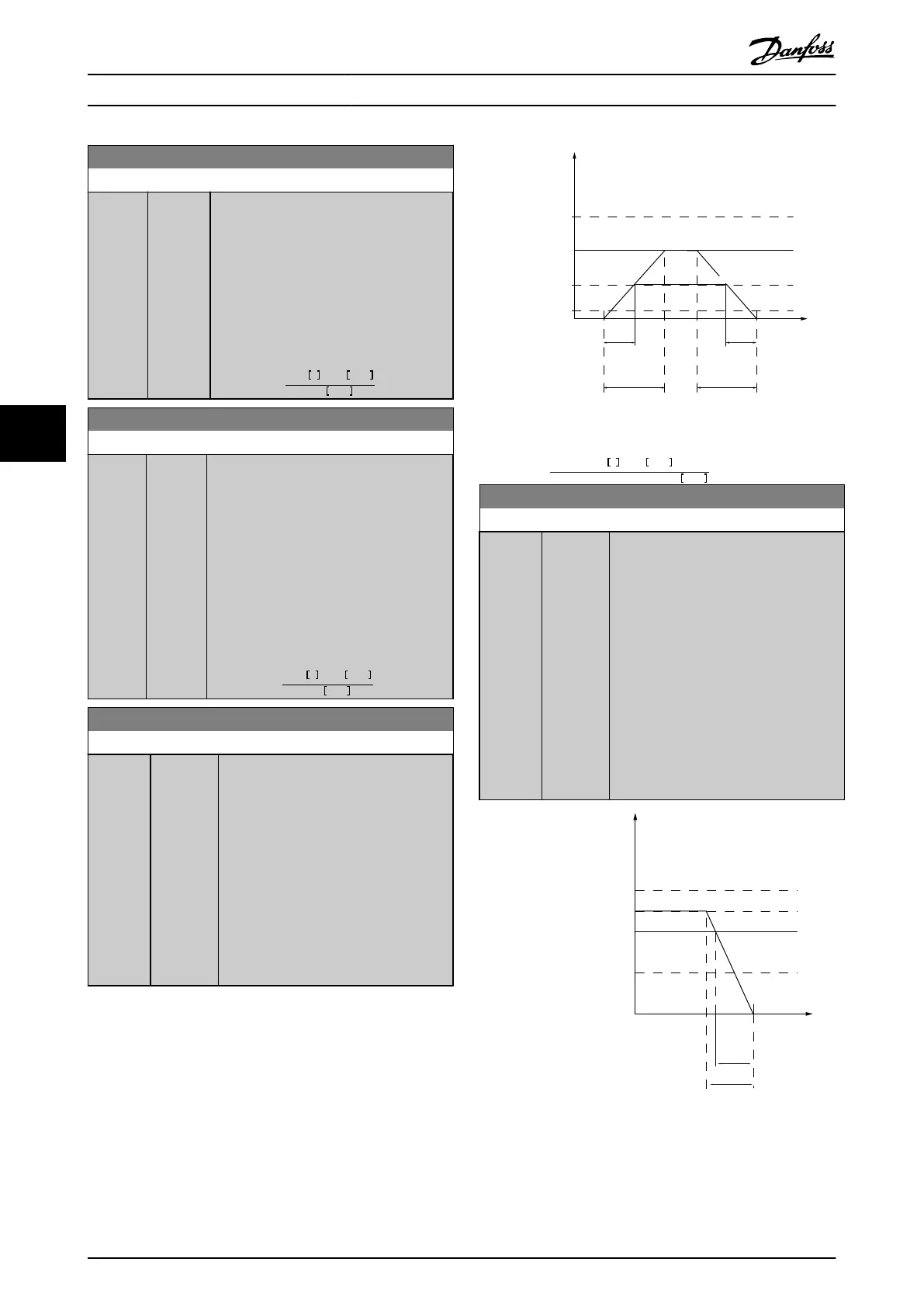

3-81 Quick Stop Ramp Time

Range: Function:

Size

related*

[0.01 -

3600.00 s]

Enter the quick–stop ramp-down time, i.e.

the deceleration time from the

synchronous motor speed to 0 RPM.

Ensure that no resultant over-voltage will

arise in the inverter due to regenerative

operation of the motor required to

achieve the given ramp-down time.

Ensure also that the generated current

required to achieve the given ramp-down

time does not exceed the current limit

(set in 4-18 Current Limit). Quick-stop is

activated by means of a signal on a

selected digital input, or via the serial

communication port.

130BA069.10

Time

RPM

P 4-13 RPM

high limit

Reference

P 1-25

Motor speed

low limit

P 4-11 RPM

P 3-81

Qramp

Qstop

Illustration 6.5

Parameter Descriptions

Operating Instructions VLT

®

CDS302 and CDS303

56 MG34M302 - VLT

®

is a registered Danfoss trademark/Commercial Compressor

6

6

Loading...

Loading...