[85] SL Digital

Output F

See 13-52 SL Controller Action. The input

will go high whenever the Smart Logic

Action [43] Set dig. out. A high is executed.

The input will go low whenever the Smart

Logic Action [37] Set dig. out. A low is

executed.

[122] No alarm The output is high when no alarm is

present.

[123] Start command

active

The output is high when there is an

active Start command (i.e. via digital input

bus connection or [Hand on] or [Auto on],

and no Stop or Start command is active.

[124] Running

reverse

The output is high when the frequency

converter is running counter clockwise

(the logical product of the status bits

‘running’ AND ‘reverse’).

[125] Drive in hand

mode

The output is high when the frequency

converter is in Hand on mode (as

indicated by the LED light above [Hand

on].

[126] Drive in auto

mode

The output is high when the frequency

converter is in Hand on mode (as

indicated by the LED light above [Auto

on].

[139] Compressor

Inv. Interlock

Use with cascade controller. Logic will

stop the fixed speed compressor and give

a warning.

[140] Compressor

Inv. Interlock

Use with cascade controller. Logic will

stop the fixed speed compressor and give

a warning.

[141] Compressor

Inv. Interlock

Use with cascade controller. Logic will

stop the fixed speed compressor and give

a warning.

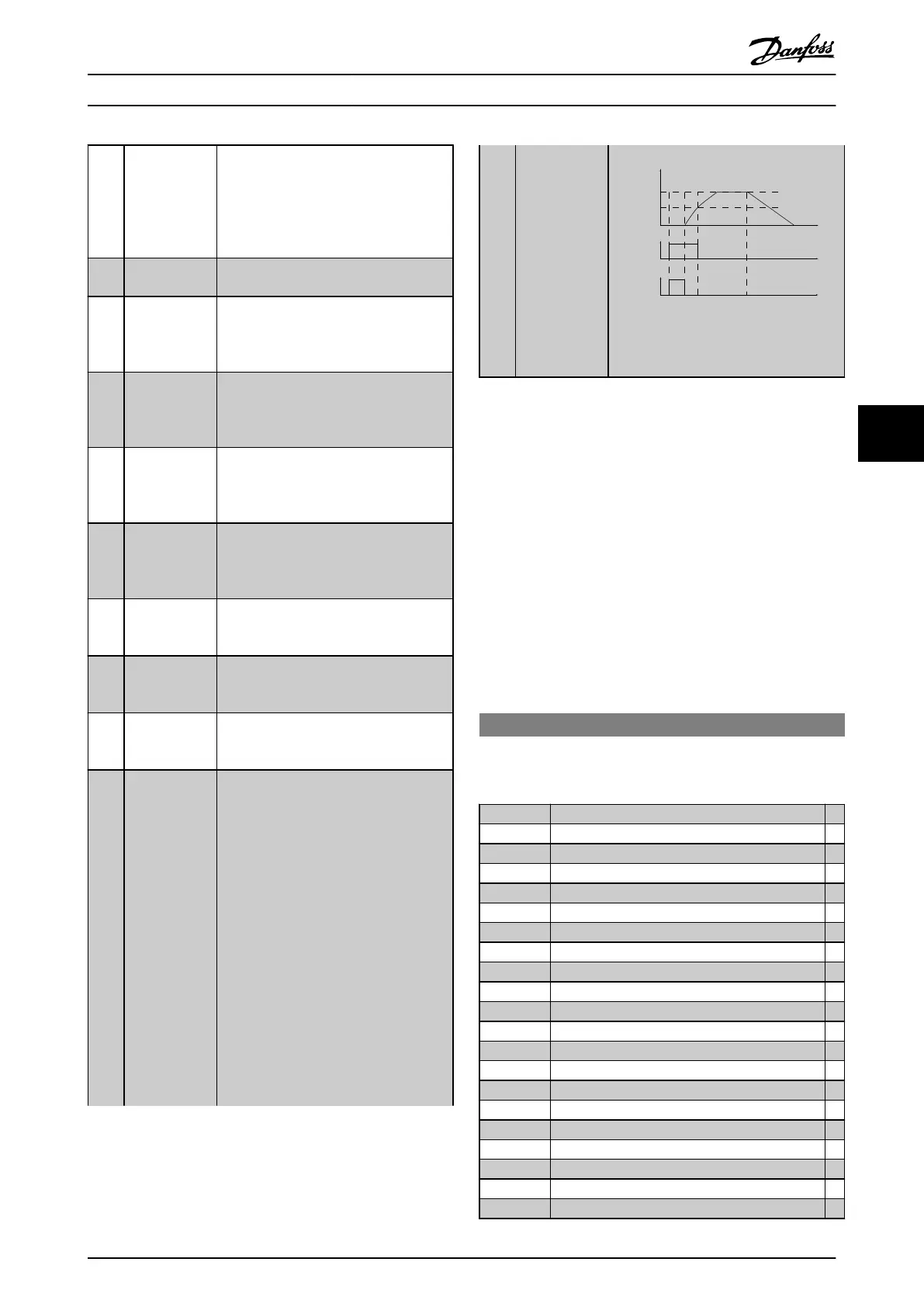

[195] Bypass Valve

Control

The bypass valve control (Digital/Relay

output in the frequency converter) is used

for compressor systems to unload the

compressor during start-up by using a

bypass valve. After the start command is

given the bypass valve will be open until

the frequency converter reaches

4-11 Motor Speed Low Limit [RPM]). After

the limit has been reached the bypass

valve will be closed, allowing the

compressor to operate normally. This

procedure will not be activated again

before a new start is initiated and the

frequency converter speed is zero during

the receiving of start signal. 1-71 Start

Delay can be used in order to delay the

motor start. The bypass valve control

principle:

Time

REF

Min

Speed

ON

Time

Time

OFF

ON

OFF

Start

Stop

130BA251.10

Speed

Illustration 6.6

The below setting options are all related to the Cascade

Controller.

Wiring diagrams and settings for parameter, see parameter

group 25-** Cascade Pack Controller or more details.

6.6.5

5-4* Relays (Dry Contacts)

NOTE

Relays 7, 8, and 9 are only available if MCB 105 relay card

is installed.

NOTE

Relay 1 is dedicated to controlling the solenoid valve.

Parameters for configuring the timing and the output

functions for the relays.

5-40 Function Relay

Array [8] (Relay 1 [0], Relay 2 [1], Relay 7 [6], Relay 8 [7],

Relay 9 [8])

[0]

No Operation

[1] Control Ready

[2] Drive Ready

[3] Drive Ready/Remote

[4] Stand-by/No Warning

[5] * Running

[6] Running/No Warning

[8] Run on Ref./No Warning

[9] Alarm

[10] Alarm or Warning

[11] At Torque Limit

[12] Out of Current Range

[13] Below Current, low

[14] Above Current, high

[15] Out of Speed Range

[16] Below Speed, low

[17] Above Speed, high

[18] Out of Feedb. Range

[19] Below Feedback, low

[20] Above Feedback, high

[21] Thermal Warning

Parameter Descriptions

Operating Instructions VLT

®

CDS302 and CDS303

MG34M302 - VLT

®

is a registered Danfoss trademark/Commercial Compressor 65

6

6

Loading...

Loading...