6.5 STO Technical Data

The Failure Modes, Eects and Diagnostic Analysis (FMEDA) is performed based on the following assumptions:

•

FC 280 takes 10% of the total failure budget for an SIL2 safety loop.

•

Failure rates are based on the Siemens SN29500 database.

•

Failure rates are constant; wear-out mechanisms are not included.

•

For each channel, the safety-related components are considered to be of type A with a hardware fault tolerance

of 0.

•

The stress levels are average for an industrial environment and the working temperature of components is up to

85 °C (185 °F).

•

A safe error (for example, output in safe state) is repaired within 8 hours.

•

No torque output is the safe state.

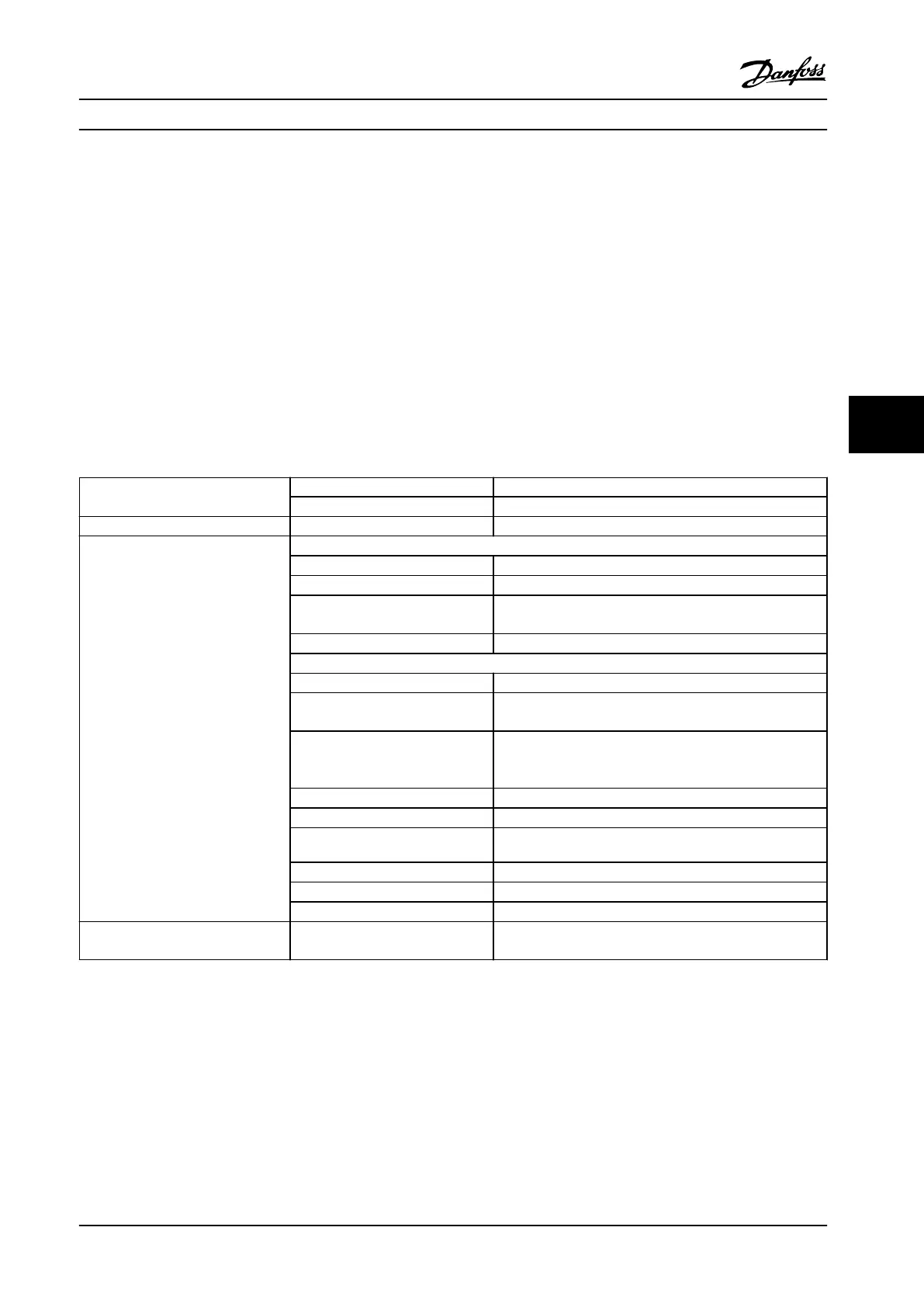

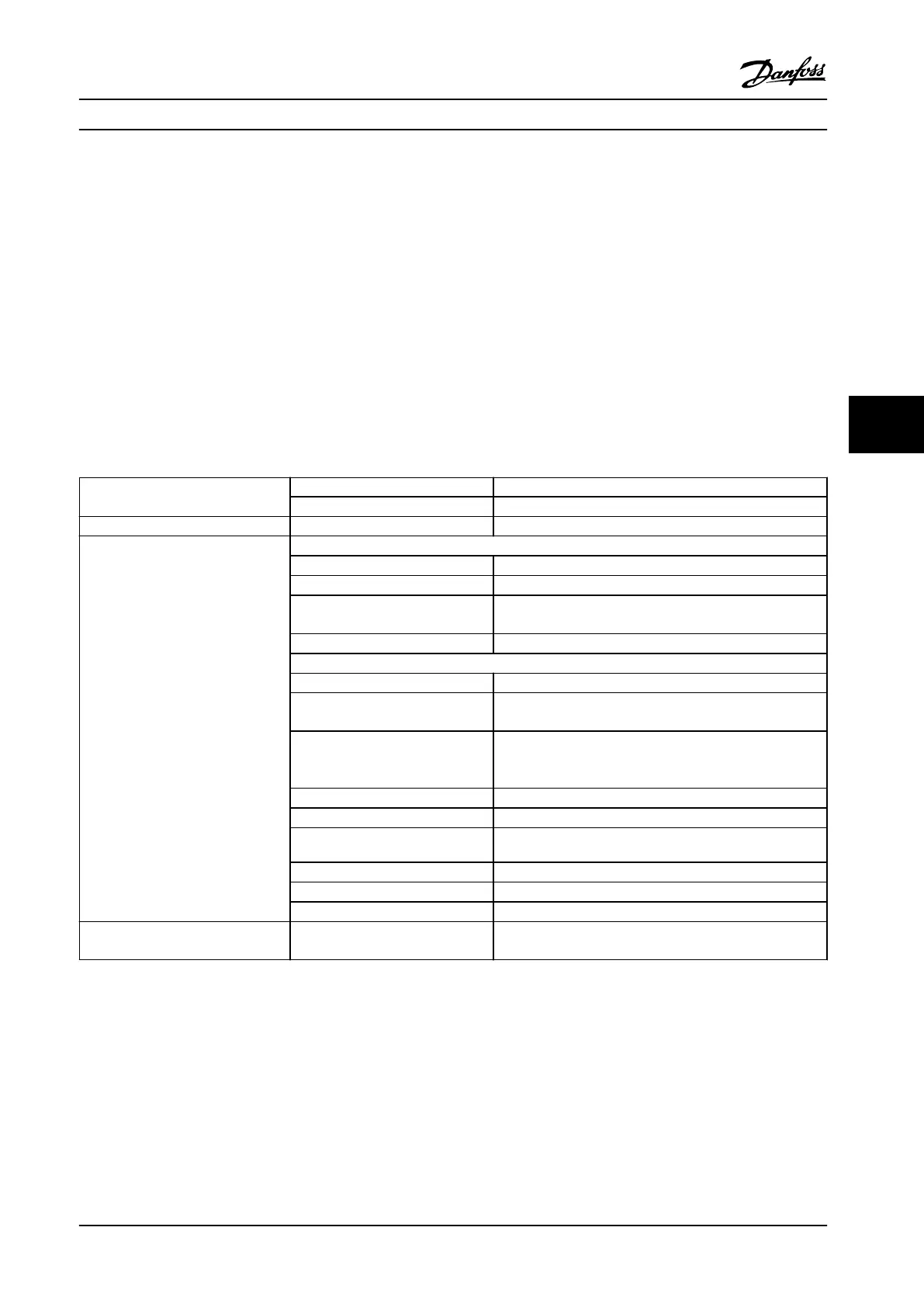

Safety standards

Safety of Machinery ISO 13849-1, IEC 62061

Functional Safety IEC 61508

Safety function Safe Torque O IEC 61800-5-2

Safety performance

ISO 13849-1

Category Cat. 3

Diagnostic Coverage (DC) 60% (Low)

Mean Time to Dangerous Failure

(MTTFd)

2400 years (High)

Performance Level PL d

IEC 61508/IEC 61800-5-2/IEC 62061

Safety Integrity Level SIL2

Probability of Dangerous Failure per

Hour (PFH) (High Demand Mode)

7.54E-9 (1/h)

Probability of Dangerous Failure on

Demand (PFD

avg

for PTI = 20 years)

(Low Demand Mode)

6.05E-4

Safe Failure Fraction (SFF) > 84%

Hardware Fault Tolerance (HFT) 1 (Type A, 1oo2D)

Proof Test Interval

2)

20 Years

Common Cause Failure (CCF) β = 5%; β

D

= 5%

Diagnostic Test Interval (DTI) 160 ms

Systematic Capability SC 2

Reaction time

1)

Input to output response time Enclosure sizes K1–K3: Maximum 50 ms

Enclosure sizes K4 and K5: Maximum 30 ms

Table 6.3 Technical Data for STO

1) Reaction time is the amount of time from an input signal condition that triggers the STO until the torque is o on the motor.

2) For the way to perform proof test, please refer to chapter 6.4 Maintenance and Service for STO.

Safe Torque O (STO) Instruction Manual

MG07A122 Danfoss A/S © 11/2015 All rights reserved. 37

6

6

Loading...

Loading...