149

MG.10.J8.02 – VLT is a registered Danfoss trade mark

Programmable SyncPos motion controller

Syntax Example

SETCURVE curve

SYNCCMM 1 // Synchronize 1 x in CAM mode

// with marker correction

Sample

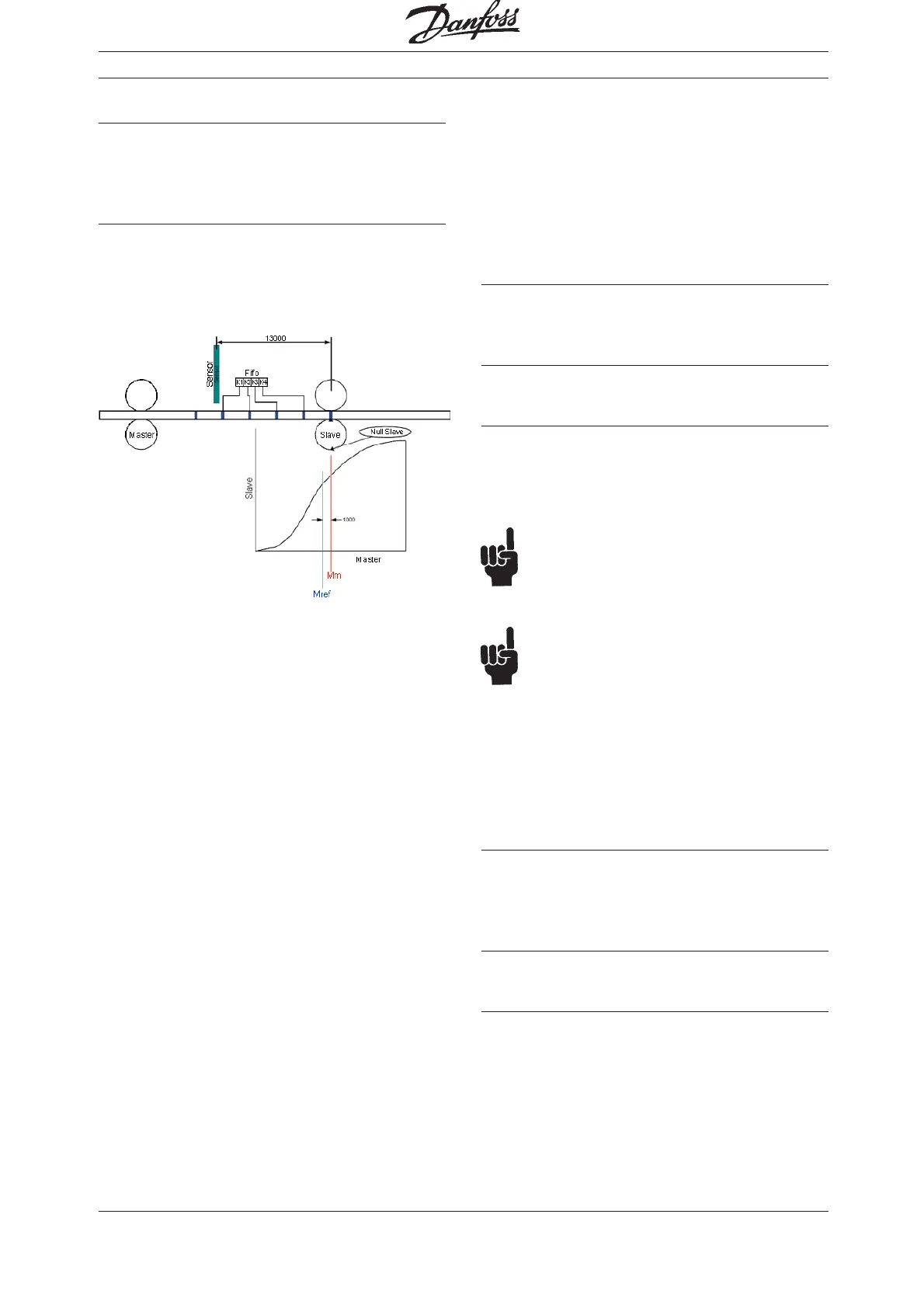

If for example curve length is 3000 and distance of

sensor to working point is 13000, we will have a

FIFO with 4 register and an offset of 1000 which

has to be concerned.

See the following diagram:

■■

■■

■ SYNCCMS

Like SYNCC, the command SYNCCMS brings

about a synchronization in CAM-Mode, but beyond

that it also performs a marker correction of the

slave. Here, the slave position is corrected, not the

curve position.

In contrast to SYNCCMM, no FIFO is created.

Summary

Synchronization in CAM-Mode with slave marker

correction

Syntax

SYNCCMS num

Parameter

num = number of curves to be processed;

0 = the drive remains in CAM-Mode until

another mode is started with commands

such as MOTOR STOP, CSTART, POSA etc.

NB!

SYNCCMS does not start the slave drive nor

does it interrupt on-going motions (e.g. CVEL),

only SYNCCSTART does.

NB!

The drive remains in CAM-Mode until num

curves have been processed successfully.

If the synchronization (after num curves) is being

closed normally, the start stop point pair 2 will be

used – if no SYNCCSTOP with a corresponding

point pair is defined – in order to stop the drive. It

will then come to a stop at the position slavepos

(see parameters).

Marker signal

The marker can be the zero pulse from the enco-

der or an external 24 volt signal:

I5 =master; I6 = slave

Command Group

CAM

Syntax Example

SETCURVE curve

SYNCCMS 0 // Synchronization in CAM-Mode

// with slave marker correction

Software Reference

Loading...

Loading...