77

MG.10.J8.02 – VLT is a registered Danfoss trade mark

Programmable SyncPos motion controller

■■

■■

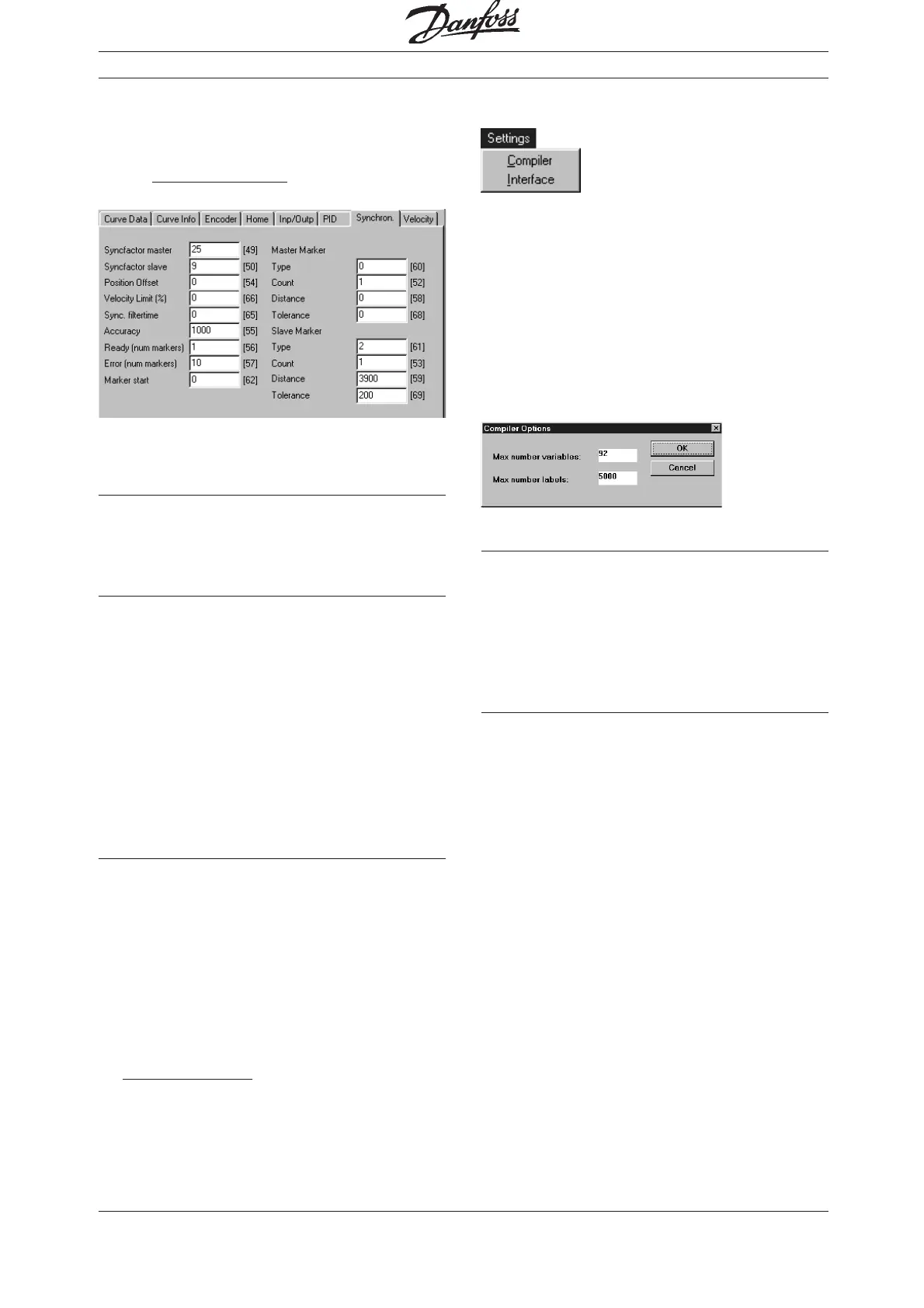

■ Index Card Synchronization

For further information regarding content, units, input

areas and factory settings of these parameters, con-

sult the

Parameter Reference section or select the

input field of the parameter and press [F1].

For a CAM Control you need following parameters:

Syncfactor Master and Slave

The two parameters SYNCFACTM [49] and

SYNCFACTS [50] are used to determine the MU

units in the cam control.

Marker Distance

Enter the distance of the sensor to the processing

point here; in the case of master markers in

SYNCPULSM [58] and in the case of slave markers

in SYNCPULSM [59].

The position of the curve where the marker is detec-

ted is calculated from the master marker position

and the marker distance. This position is shown as a

green line in the curve profile and allows you to fix

the correction area.

Activate → "MASTER MARKER "or "SLAVE

MARKER" for this purpose.

Tolerance

Tolerance window for the appearance of the master

markers (Marker monitoring) SYNCMWINM [68] or

the slave markers SYNCMWINS [69]. The tolerance

window is shown as a green area in the curve

profile. Activate → "MASTER MARKER" or

"SLAVE MARKER" for this purpose.

■■

■■

■ Index card Velocity

For further information regarding content, units, input

areas and factory settings of these parameters, consult

the

Parameter Reference section or select the input

field of the parameter and press [F1].

In addition, the maximum velocity and acceleration

reached in the current application are calculated

here in qc/scan time. The display in the curve profile

occurs in units. Activate → "VELOCITY" or

"ACCELERATION" for this purpose.

■■

■■

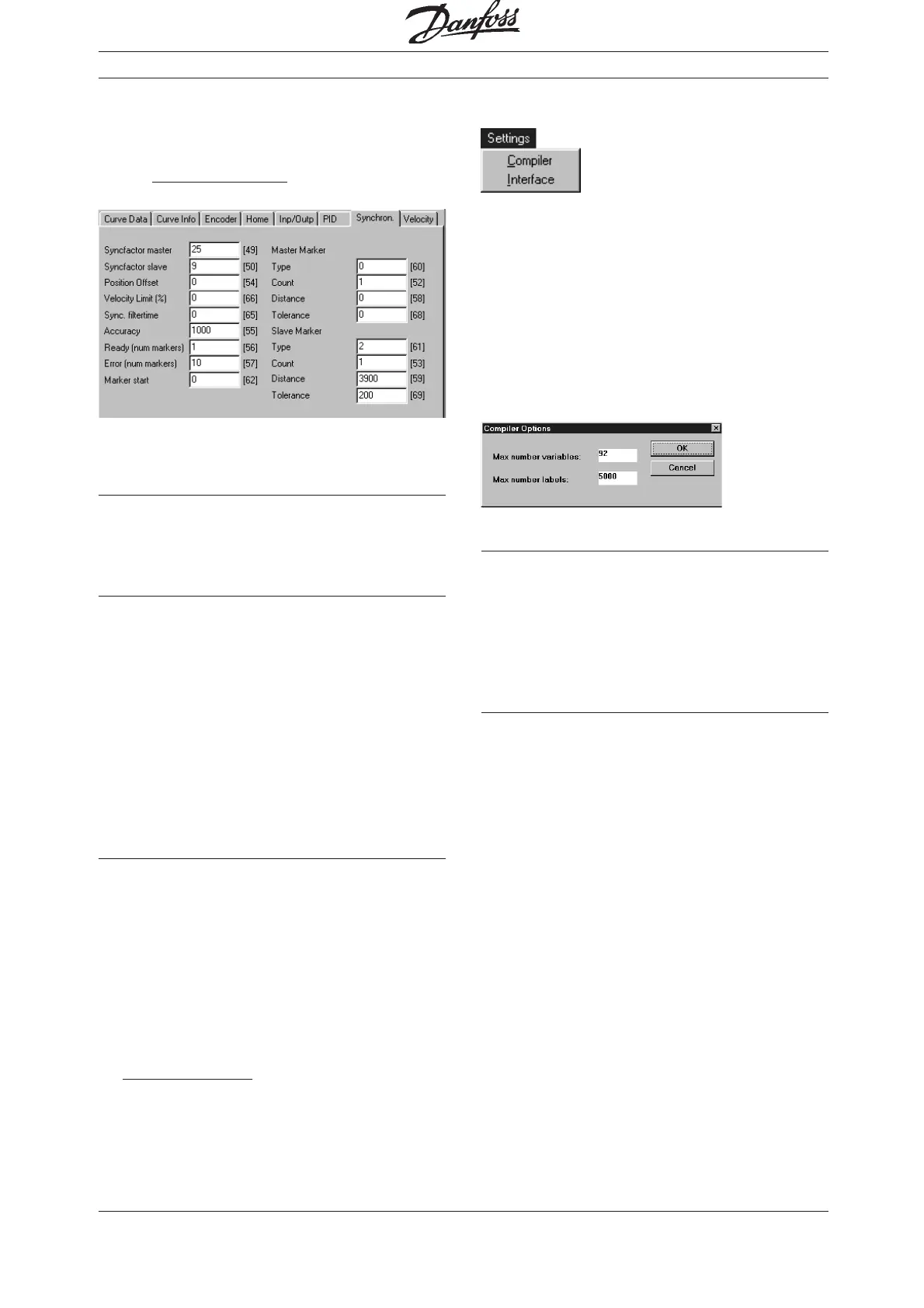

■ "SETTINGS" menu

This menu offers compiler options and interface

settings. You can set the colors in the editor as you

wish. If you would like to change the language of the

user interface, please see below.

■■

■■

■ "COMPILER"

The default values for the compiler options are set

accordingly for most applications. Thus, they do not

require too much memory and, at the same time,

they allow the necessary input to be made.

Maximum number of variables

The number of variables has a direct effect on the

amount of memory available in the option. It is im-

portant to remember that an array also occupies the

space of a variable.

If you need more than 92 variables (incl. arrays)

then increase this number.

Maximum number of labels

The maximum number of labels determines how

much memory is available for internal hyperlinks.

Internal hyperlinks are automatically created for all

branches of the program (GOTO, IF, LOOP, REPEAT,

WHILE, GOSUB) during compiling. The

recommended range is between 100 and 500 inter-

nal labels.

Increase the maximum values permitted if the num-

ber of labels is not sufficient for text input.

Loading...

Loading...