45

MG.10.J8.02 – VLT is a registered Danfoss trade mark

Programmable SyncPos motion controller

■■

■■

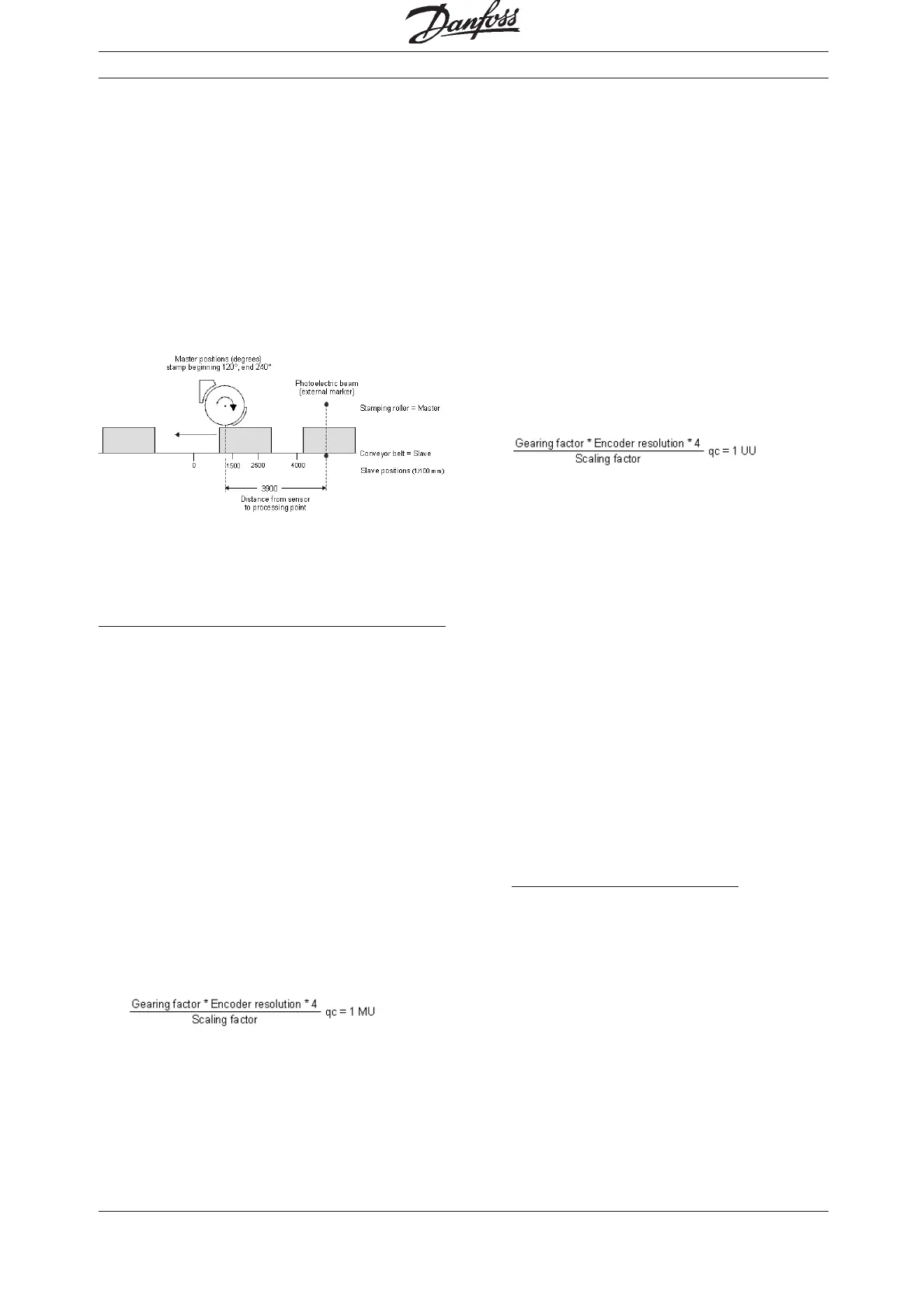

■ Example: Slave Synchronization with Marker

In the following example, the conveyor belt is the

slave and the stamp roller the master, since the

take-up and delivery of the dye must be conti-

nuous for a uniform printing process. A maximum

of 20 cardboard boxes are transported on the con-

veyor belt per minute. The distance of the boxes is

not larger than one master cycle length. Stamp roller

and box must run in sync during the printing

operation:

In contrast to the synchronization with master

marker correction, here the slave position is being

corrected instead of the curve.

How to edit a curve for the Slave Synchronization

1. Set the VLT with the required parameters and

save these user parameters with

"PARAMETERS" → "SAVE TO FILE" with the

extension „cnf“.

2. Start the → "CAM-EDITOR" and load this cnf

file with "FILE" → "LOAD CNF".

3. Determine the gearing factor of the master in

MU units.

Gearing factor = 5/1

Encoder resolution (Increm. encoder) = 500

One revolution of the roller is 360 degrees. We

are going to work with a resolution of

1/10 degrees. Therefore we are dividing one

revolution of the roller into 3600 work units:

Scaling factor = 3600

Enter these whole number values in the index

card → "SYNCHRONIZATION":

Syncfactor Master [49] = 25

Syncfactor Slave [50] = 9

4. Enter the gearing factor of the slave in user

untis [UU]:

The input should be possible in 1/10 mm

resolution.

The drive is connected with the conveyor belt

by means of a gearing of 25:11; i.e. the motor

makes 25, the drive pulley 11 revolutions.

Gearing factor = 25/11

Incremental encoder directly on the master

drive; encoder resolution = 4096

The drive pulley has 20 teeth/revolution,

2 teeth correspond to 10 mm, thus 1 revolution

corresponds to = 100 mm conveyor belt feed

or 1000/10 mm.

Thus, the scaling factor is 1000

Enter these values in the index card →

"ENCODER":

User factor numerator [23] = 2048

User factor denominator [26] = 55

5. Determine a whole number factor for the inter-

vals in the index card → "CURVE DATA" so

that the fixpoints are on the interpolation

points.

A complete cycle length of the master is

360 degrees; this corresponds to 3600 MU.

The → "NUMBER OF INTERVALS" = 36 pro-

duces a reasonable interval time of 27.7ms.

6. Define → "FIX POINTS" for the roller (slave)

and the conveyor belt (master) and the point

type „1“ for curve points. The function →

"SNAP ON GRID" should be activated.

Points Master Slave Type

10 0 1

2 1200 1500 1

3 2400 2500 1

4 3600 4000 1

7. Master and slave must run synchronously with

the same velocity between the master position

1200 to 2400. For this, you need to have a

straight line which is determined with two tan-

gent points. Thus, for these two fixpoints you

must define the → "TYPE" = 2 for tangent point

and insert two fixpoints so that the curve can be

calculated.

CAM Control

Loading...

Loading...