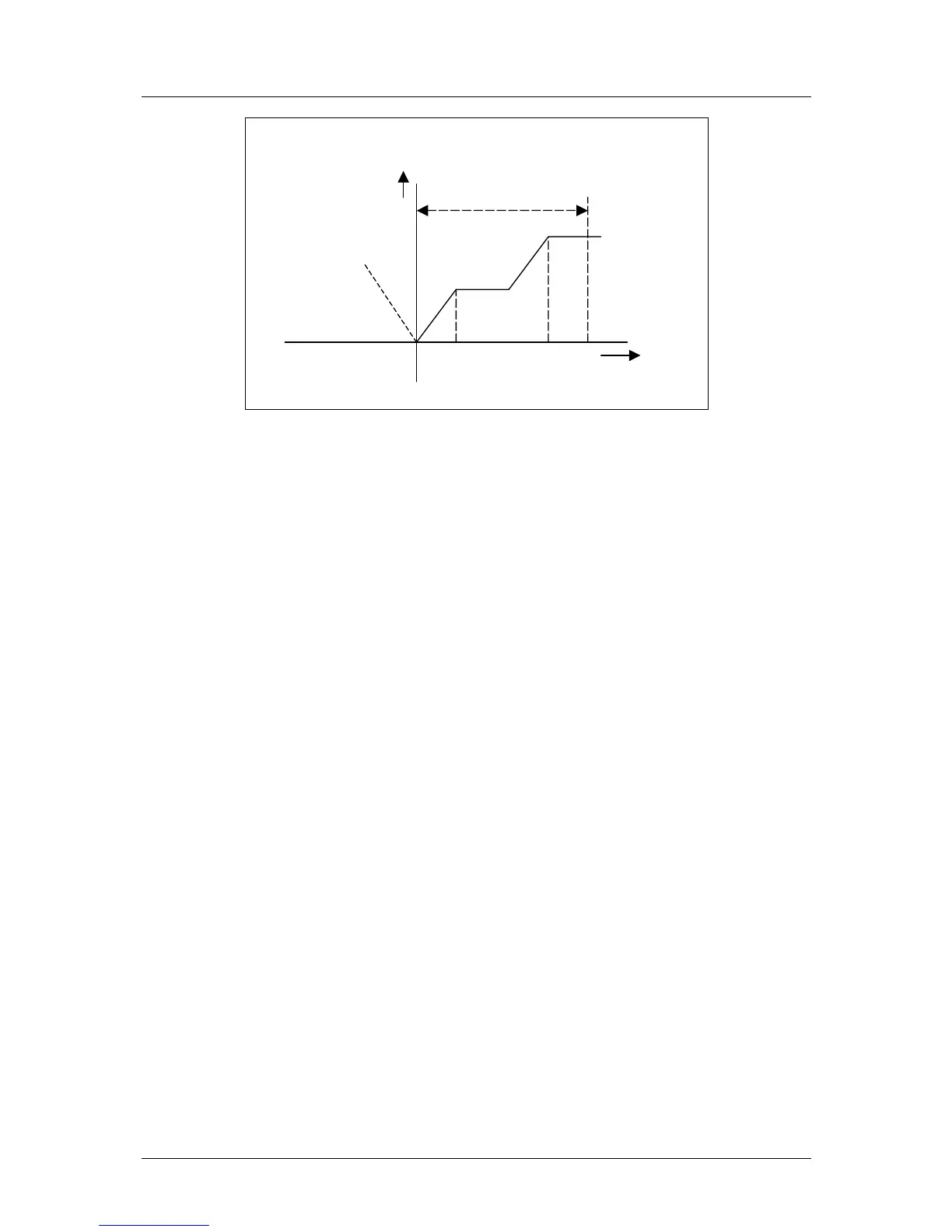

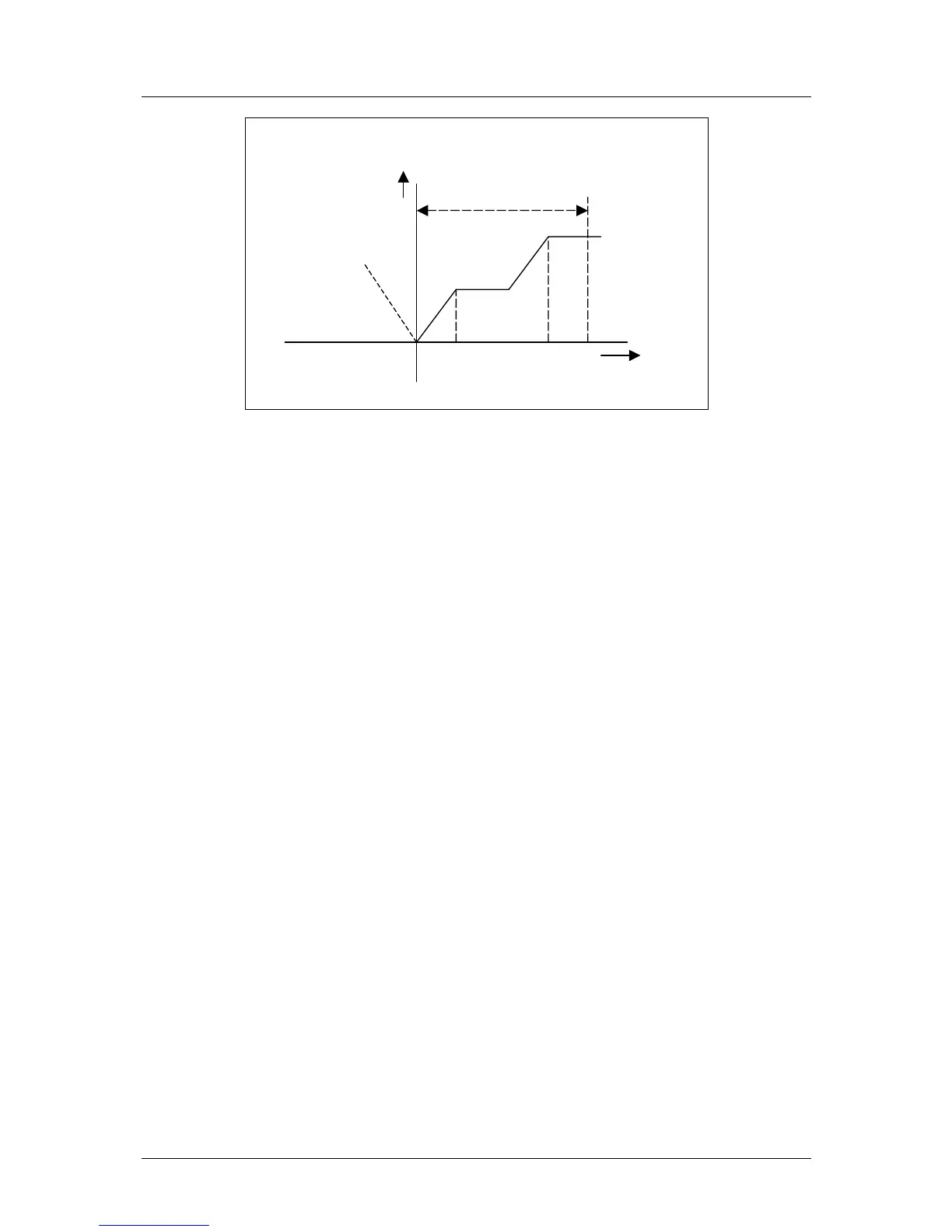

One side positioning is useful to overcome mechanical inaccuracies in the spindle. Final

positioning of the axis is always done from a higher to a lower position. So when the axis

moves from a high to a low position, positioning is done immediatly. When the axis moves

from a low to a high position, the axis will move to the overrun position (= programmed

position +OR). After that, the axis starts moving in the opposite direction and positioning

takes place.

When the difference between the new programmed position and the actual position is smaller

then BSS the axis is always moved to the overrun position first, also in case of two side

positioning.

Choosing 1-side or 2-side positioning is done with the parameter ‘Spindle allowance’.

2.3.3. Unipolar system

A unipolar system is a modified AC system. Normally, the analog output can be used for AC

control: positive voltage (one or two levels) for one direction, negative voltage for the other

direction.

In a unipolar system the output voltage is always positive, the movement direction is indicated

by digital outputs. This is the only difference between standard AC implementation and

unipolar AC implementation.

Loading...

Loading...