7

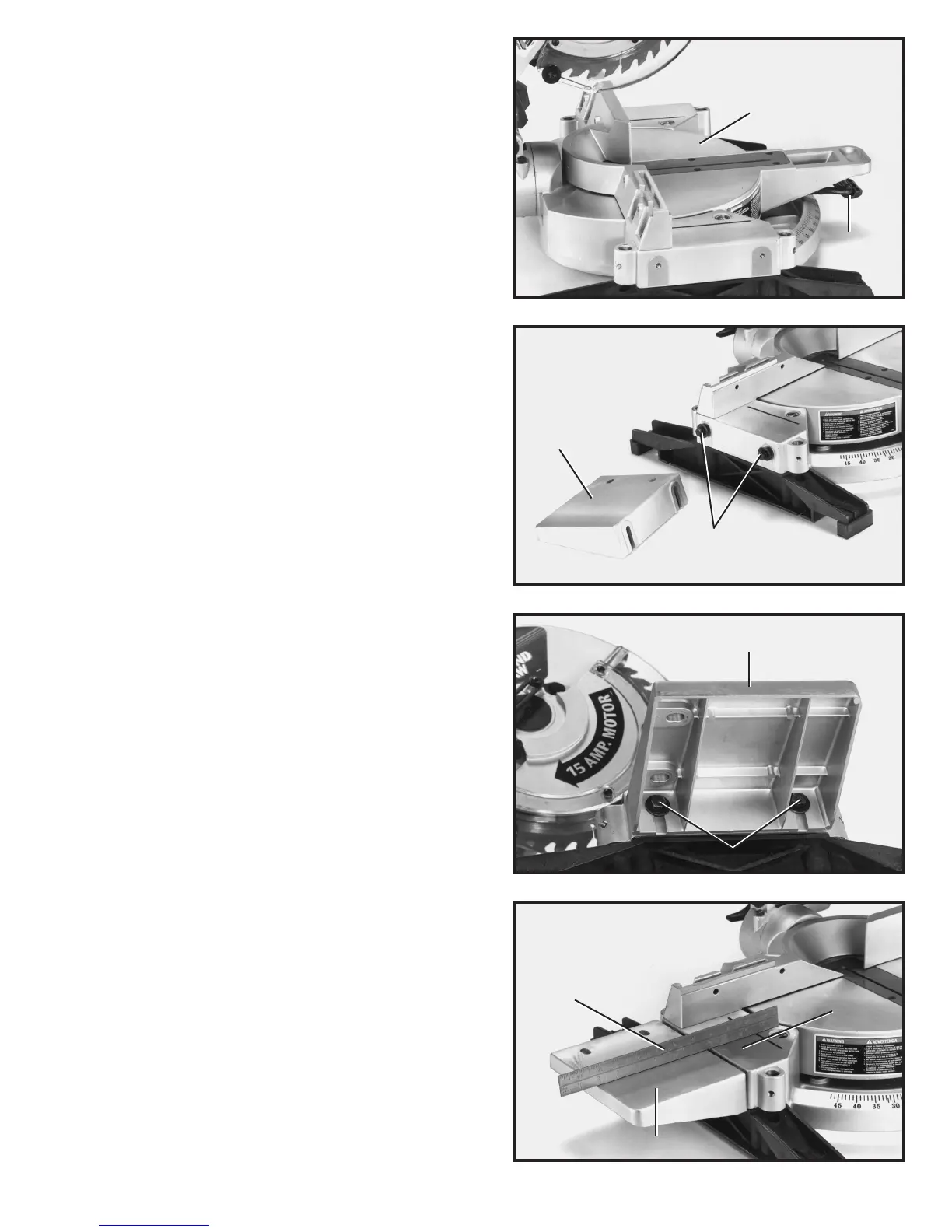

Fig. 7

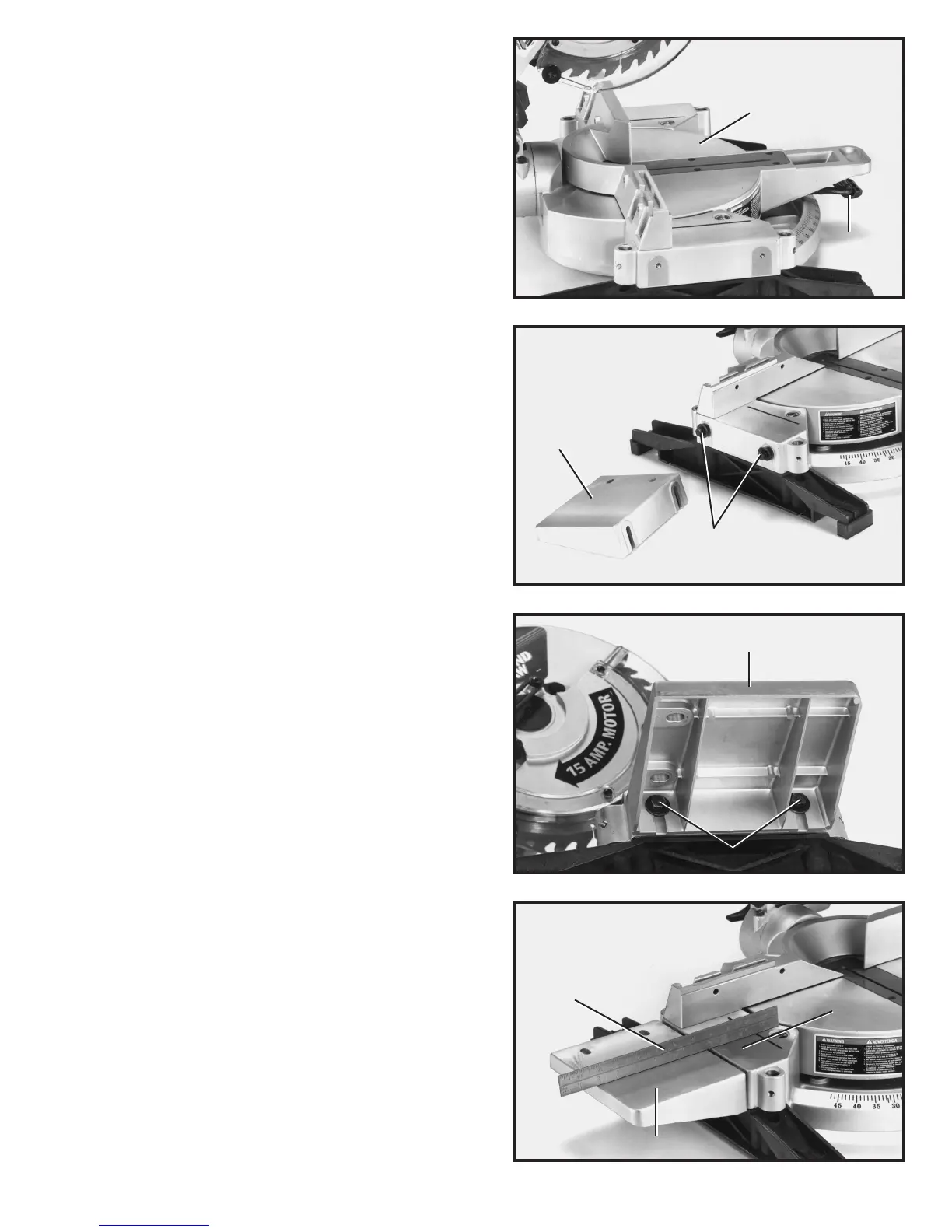

Fig. 7A

Fig. 7B

Fig. 7C

2. Fig. 7, illustrates the t able (B) in the 90 degree

straight cut-of f position. NOTE: Table lock lever (A) must

be depressed when rotating t able. When lock lever (A) is

not depressed, the t able is in the locked position and

cannot be moved.

3. For proper operation and adjustment of the t able, refer

to sections, R O T A TING TABLE FOR MITER CUTTING,

ADJUSTING CLAMPING ACTION O F TABLE LOCKING

MECHANISM and ADJUSTING SLIDING FIT BETWEEN

M O VABLE TABLE AND BASE.

ASSEMBLING EXTENSION

TABLE AND FENCE SLIDE

1. Place 5/16 lockwasher and 5/16 flat washer on

each 1/2 long hex head screw (A) Fig. 7A, and thread

the two screws (A) into the two threaded holes on lef t

side of saw t able, as shown. NOTE: Only thread the

screws a few threads into the holes at this time.

2. Assemble the table extension (B) Figs. 7A and 7B, to

lef t side of saw t able making sure groove of t able exten -

sion (B) is inside flat washers as shown in Fig. 7B.

3. Using a straight edge (C) Fig. 7C, make cert ain

extension t able (B) is level with saw t able (D) as shown,

and tighten the two screws (A) Fig. 7B.

B

A

B

A

B

A

B

C

D

Loading...

Loading...