Hexa. Deci. Hexa. Deci.

CVIx II - Data Outputs => PLC Inputs

0x0000 0000 0x0000 0000 CVIx II Outputs R 1 Bool

--- --- --- --- --- --- --- ---

CVIx II - Data Inputs <= PLC Outputs

0x0000 0000 0x0000 0000 CVIx II Inputs W 1 Bool

--- --- --- --- --- --- --- ---

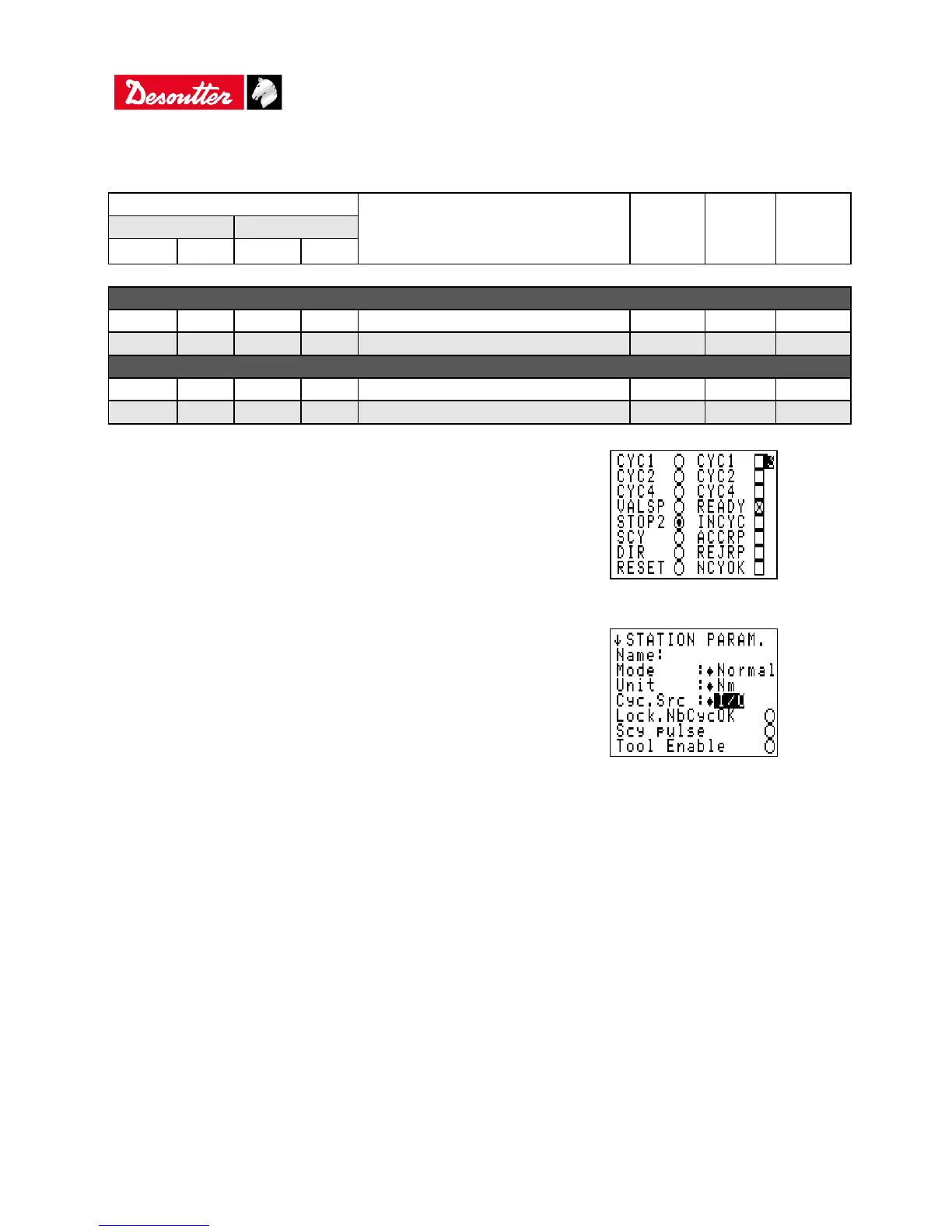

2.2.1. Inputs & Outputs assignment

The inputs & outputs mapping depends on Station I/O configuration.

You can configure Inputs and Outputs to match your requirements.

NOTE: For CVIL II controllers, the input 5 is always linked to Quick stop 2.

2.2.2. Inputs Descriptions

Cycle 1/2/4/8: Binary coded 1-2-4-8 cycle selection.

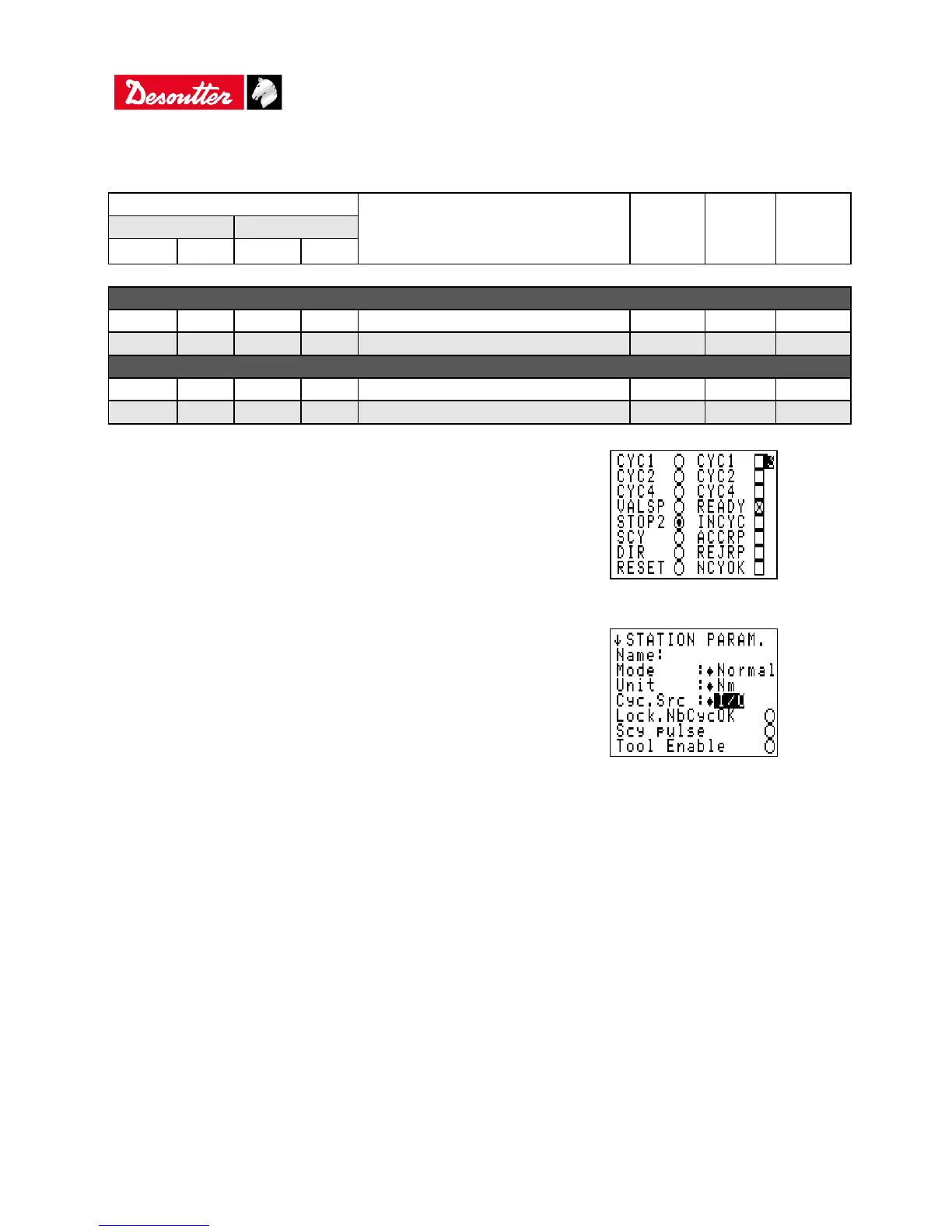

The Cycle number selection 00 to 15 is only taken

into consideration by the CVIx II if the “Source of

cycle number” is set to “I/O” in the station parameters.

Start Cycle: The tool runs as long as the signal is on “1”. When the signal drops, the cycle stops.

Direction: Activates the untightening direction mode of the spindle at the “Start cycle”.

Reset: Reset station tightening reports, all cycles’ counters, saved barcode.

Error Acknowledge: When the error acknowledgement option is activated in the station parameters, the start of

the spindle is not authorized after a reject report. The “error acknowledgement” input must

be validated (pulse) to let the spindle start again.

By activating the error acknowledge input, the reject report output is reseted.

Spindle Validation: Allows, or not, the start cycle of the spindle(s).

The spindle validation input is only taken into consideration by the CVIxII if the spindle

validation source is set in the station parameters.

Spindle Val Rev: Untightening validation is only controlled when “Spindle validation on reverse” option is

activated in the station parameters.

Synchro IN: Used in conjunction with Synchro OUT output to synchronise the tightening cycle phases of

several controllers (synchro waiting phase).

Loading...

Loading...